Carbon nanotube film and preparation method thereof

A carbon nanotube film, carbon nanotube technology, applied in nanotechnology, chemical instruments and methods, carbon compounds, etc., can solve the problems of low degree of axial orientation, inability to maintain structural stability, etc. Good chemical potential and structural self-sustainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

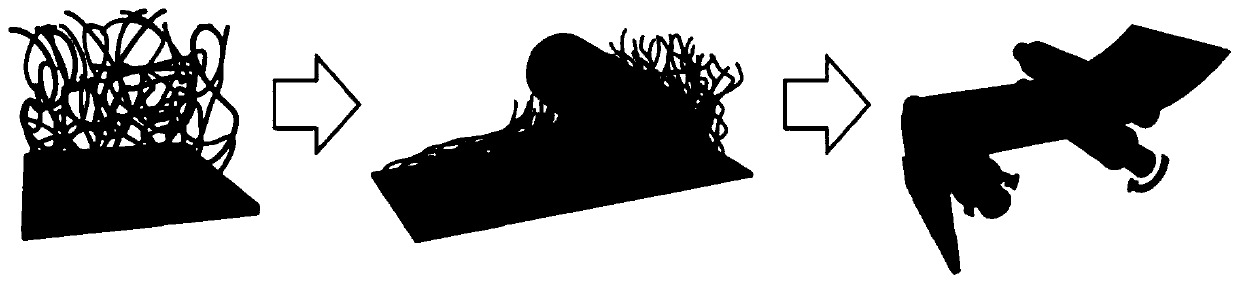

[0028] The present invention also provides a kind of preparation method of carbon nanotube thin film, and this preparation method comprises the following steps:

[0029] In the first step, the non-array carbon nanotube material is grown on the silicon wafer by ion reactive etching method and water-assisted chemical vapor deposition method. Specifically, by controlling the reaction gas flow rate, growth time and other conditions, the power of the ion reactive etching is 18W, the gas source is Ar, the growth temperature of the water-assisted chemical vapor deposition method is 750°C, and the C 2 h 4 The flow rate is 100sccm, and the growth time is 20min; the prepared non-array carbon nanotube material is mainly composed of 3-walled (average tube diameter: 8.1nm) carbon nanotubes, the purity is as high as 99.98%, the length of the carbon nanotubes is greater than 800μm, and the density About 9.7mg / cm 3 .

[0030] Step 2, peeling the prepared non-array carbon nanotube material ...

Embodiment 1

[0034] The preparation method of the carbon nanotube film provided by the first embodiment of the present invention mainly includes the following steps:

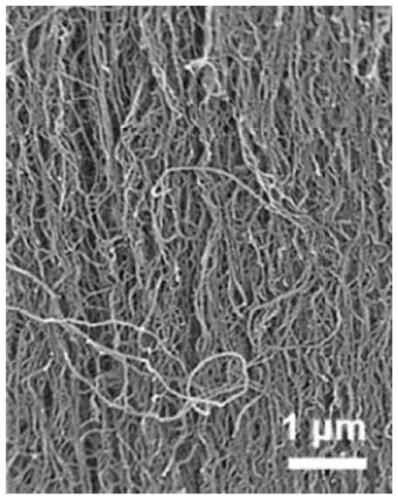

[0035] (1) The silicon wafer (5 cm in diameter) was ultrasonically cleaned in ethanol for 10 min to remove dust on the surface, and then blown to a dry state with nitrogen. After plating the catalyst film on the silicon wafer, the ion reactive etching method was used to reduce the density of the catalyst, and the non-array carbon nanotube material was grown in a tube furnace (750°C). The prepared non-array carbon nanotube material was mainly composed of 3 The wall (average tube diameter is 8.1nm) is composed of carbon nanotubes, the purity is as high as 99.98%, the length of carbon nanotubes is greater than 800μm, and the density is about 9.7mg / cm 3 .

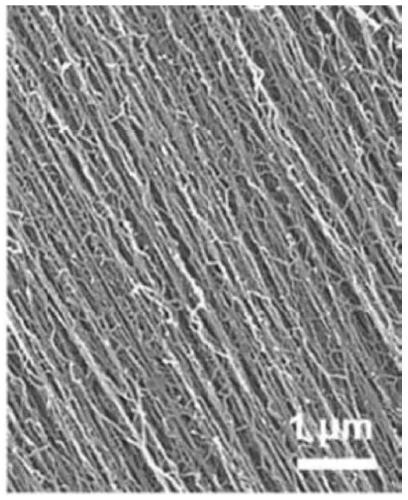

[0036] (2) peeling off the non-array carbon nanotubes from the silicon wafer, and preparing a carbon nanotube film with a nano-groove structure through a mechanical stretchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com