A kind of carbon nanotube fiber and preparation method thereof

A carbon nanotube fiber, carbon nanotube technology, applied in the direction of fiber chemical characteristics, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of poor capacitance characteristics of carbon nanotube fibers, Fermat twist, etc., to reduce Effective surface area available, reduced inter-embedding, improved structural recoverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

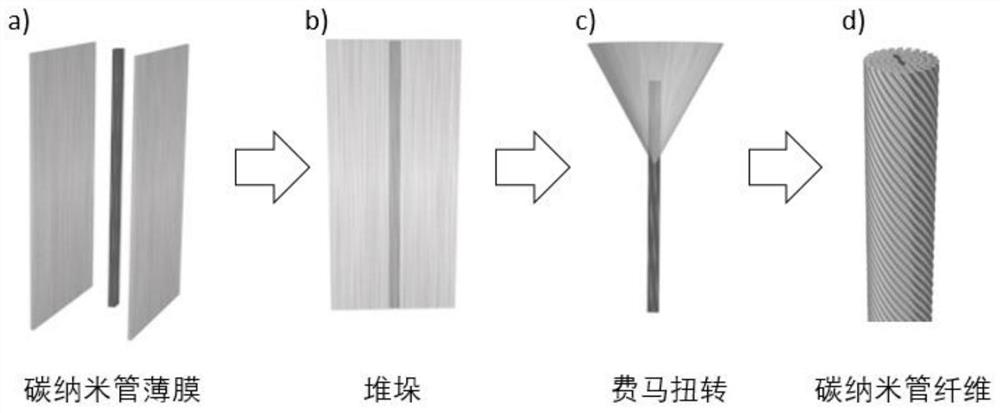

[0031] The present invention also provides a kind of preparation method of carbon nanotube fiber, and this preparation method comprises the following steps (wherein steps 1, 2 and steps 3, 4 are in no particular order):

[0032] Step 1, using the physical vapor deposition method and the water-assisted chemical vapor deposition method to grow the carbon nanotube array material on the silicon wafer.

[0033] Wherein, the physical vapor deposition process is aimed at the catalyst. Preferably, a multi-target radio frequency reactive magnetron sputtering instrument is used to physically deposit a catalyst thin film system on a clean silicon wafer substrate, including: firstly coating the substrate by reactive magnetron sputtering Aluminum oxide film, and then iron film, by controlling the coating time to obtain a catalyst film system of appropriate thickness, wherein the coating time is less than 30s for aluminum oxide and 30s-60s for iron.

[0034] The water-assisted chemical vapo...

Embodiment 1

[0045] The preparation method of the carbon nanotube fiber provided by the first embodiment of the present invention mainly includes the following steps:

[0046] (1) Sonicate silicon wafers (10 cm in diameter) in ethanol for 20 minutes to remove dust on the surface, and then blow them to a dry state with nitrogen. After coating the catalyst film on the silicon wafer, place it in a tube furnace (750°C) to grow arrayed carbon nanotube materials. The prepared arrayed carbon nanotube materials are mainly composed of 2 walls (average tube diameter is 5.4nm) and 3 walls ( The average tube diameter is 7.3nm) composed of carbon nanotubes, the purity is as high as 99.5%, the length of the carbon nanotubes is greater than 700μm, and the density is 41.3mg / cm 3 .

[0047] (2) The arrayed carbon nanotube material is peeled off from the silicon wafer, and prepared into an arrayed carbon nanotube film by a mechanical rolling process. Among them, the bulk density of the array carbon nanotu...

Embodiment 2

[0057] The preparation method of the carbon nanotube fiber provided by the first embodiment of the present invention mainly includes the following steps:

[0058](1) Sonicate silicon wafers (10 cm in diameter) in ethanol for 20 minutes to remove dust on the surface, and then blow them to a dry state with nitrogen. After coating the catalyst film on the silicon wafer, place it in a tube furnace (750°C) to grow arrayed carbon nanotube materials. The prepared arrayed carbon nanotube materials are mainly composed of 2 walls (average tube diameter is 5.4nm) and 3 walls ( The average tube diameter is 7.3nm) composed of carbon nanotubes, the purity is as high as 99.5%, the length of the carbon nanotubes is greater than 700μm, and the density is 41.3mg / cm 3 .

[0059] (2) The arrayed carbon nanotube material is peeled off from the silicon wafer, and prepared into an arrayed carbon nanotube film by a mechanical rolling process. Among them, the bulk density of the array carbon nanotub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com