Industrial method for continuously producing sodium bisulfite from byproduct Na2SO4

A technology of by-product sodium sulfate and sodium bisulfite, applied in the preparation of alkali metal sulfite, chemical instruments and methods, alkali metal sulfite/sulfite, etc., can solve the problem of sodium sulfate being worthless, Achieve the effect of avoiding clogging and ensuring reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

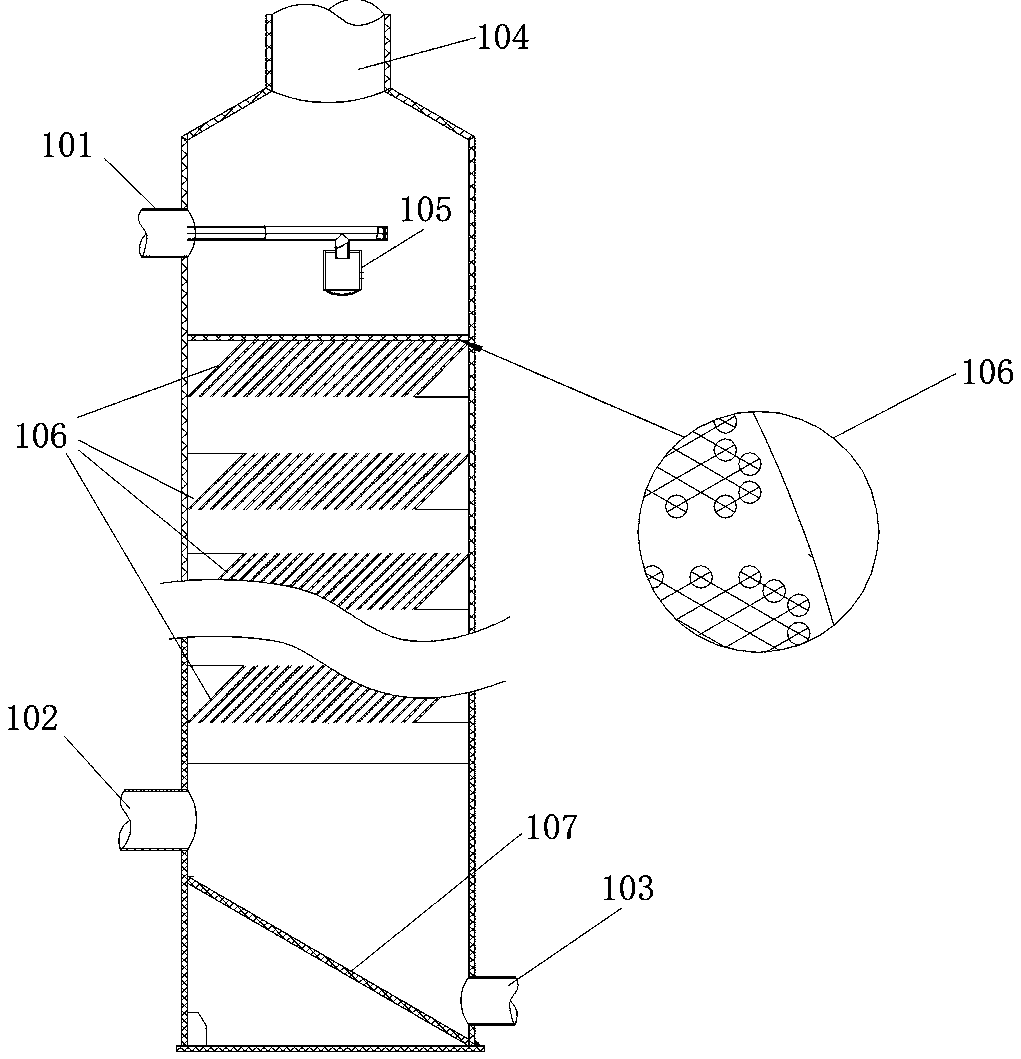

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

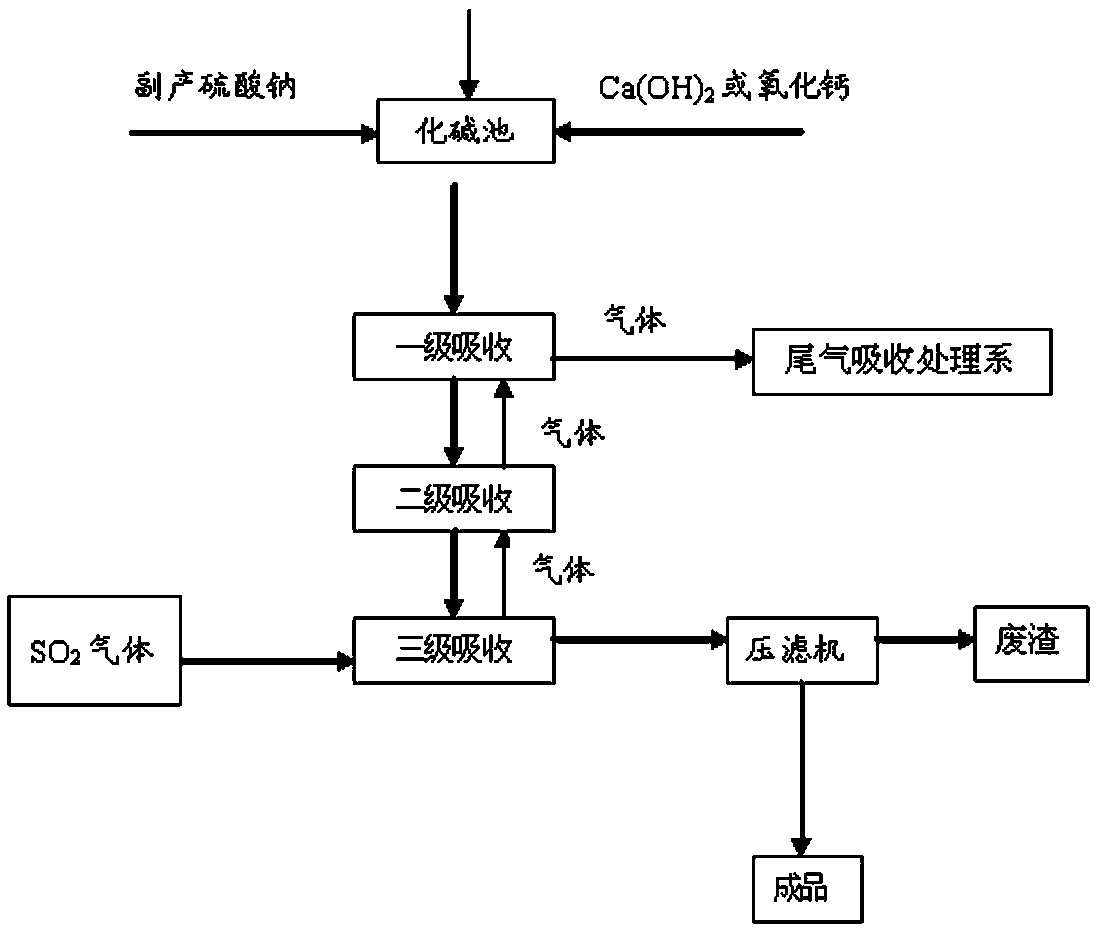

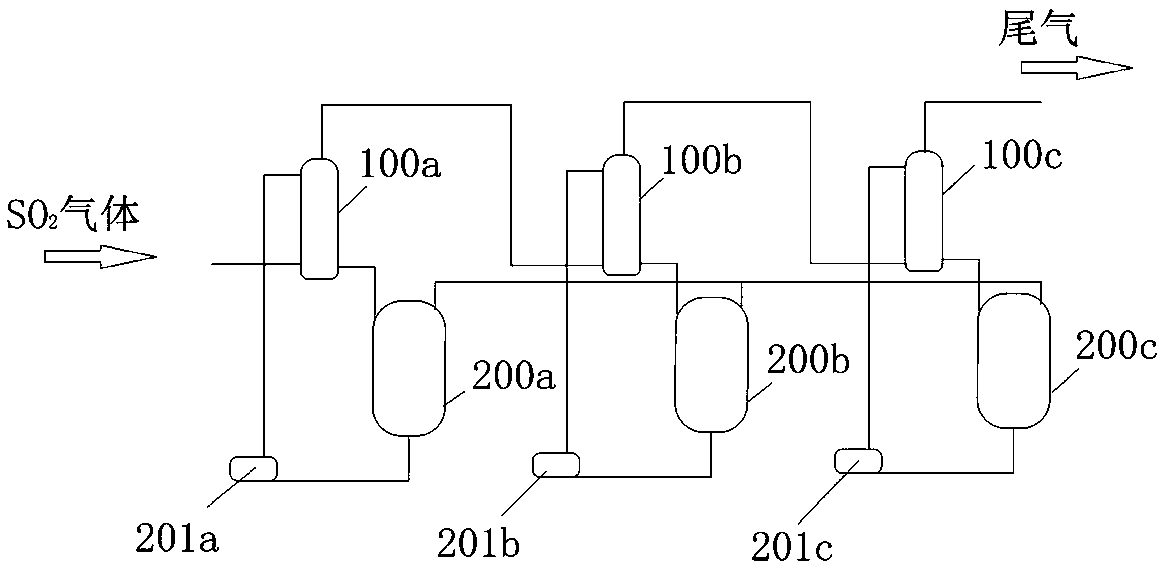

[0032] The main train of thought of the process route of the present invention is: utilize sulfur dioxide and calcium hydroxide to react to generate calcium bisulfite solution, make the calcium ion in calcium bisulfite react with sodium sulfate to generate precipitate calcium sulfate, filter out the precipitate, and the filtrate is It is sodium bisulfite solution, and the filter residue is calcium sulfate or calcium sulfite solid.

[0033] The reaction mechanism of operational route of the present invention is as follows:

[0034] SO 2 It is a colorless and irritating acid gas, easily soluble in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com