Method for comprehensively utilizing waste concrete and seawater sea-sand with low energy consumption

A technology for waste concrete and waste concrete blocks, applied in beams, manufacturing tools, surface layering devices, etc., can solve the problems of increasing sea sand usage, noise and dust pollution, high energy consumption, etc., to alleviate the shortage of river sand, Good seismic performance and the effect of saving fresh water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

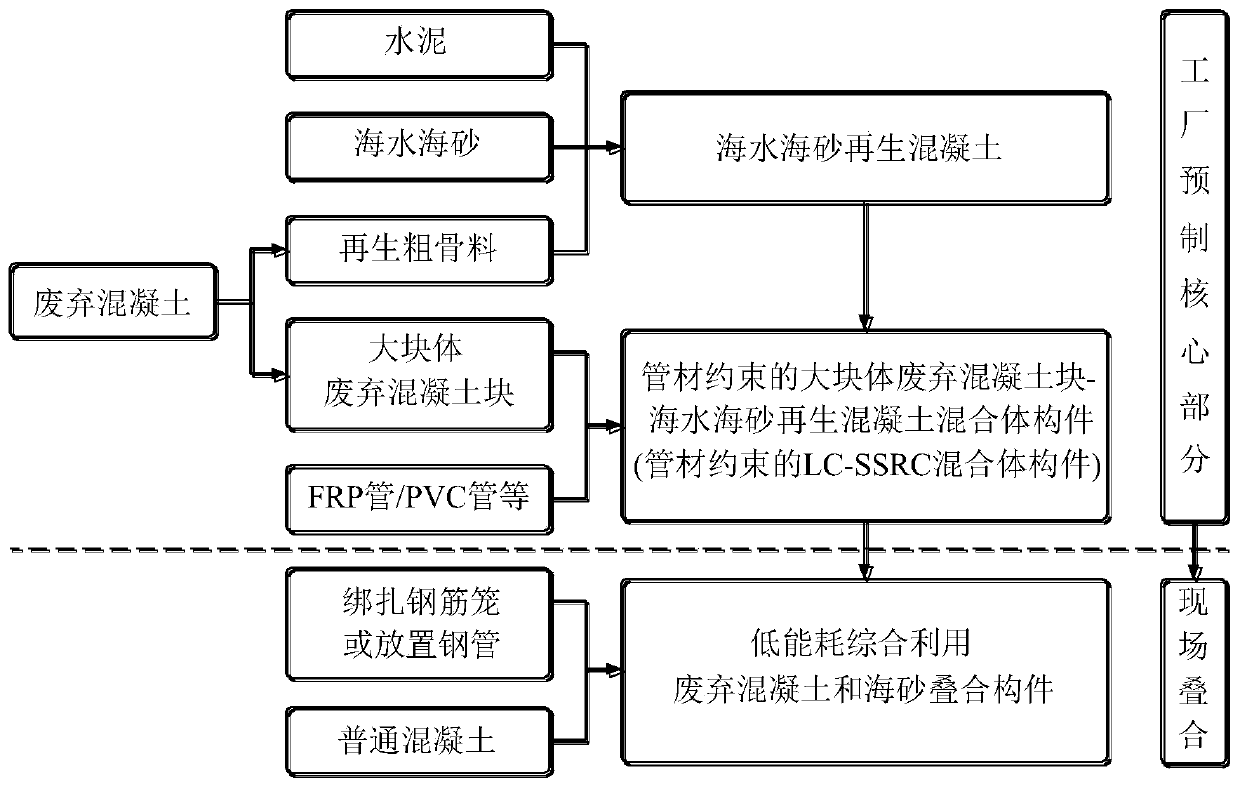

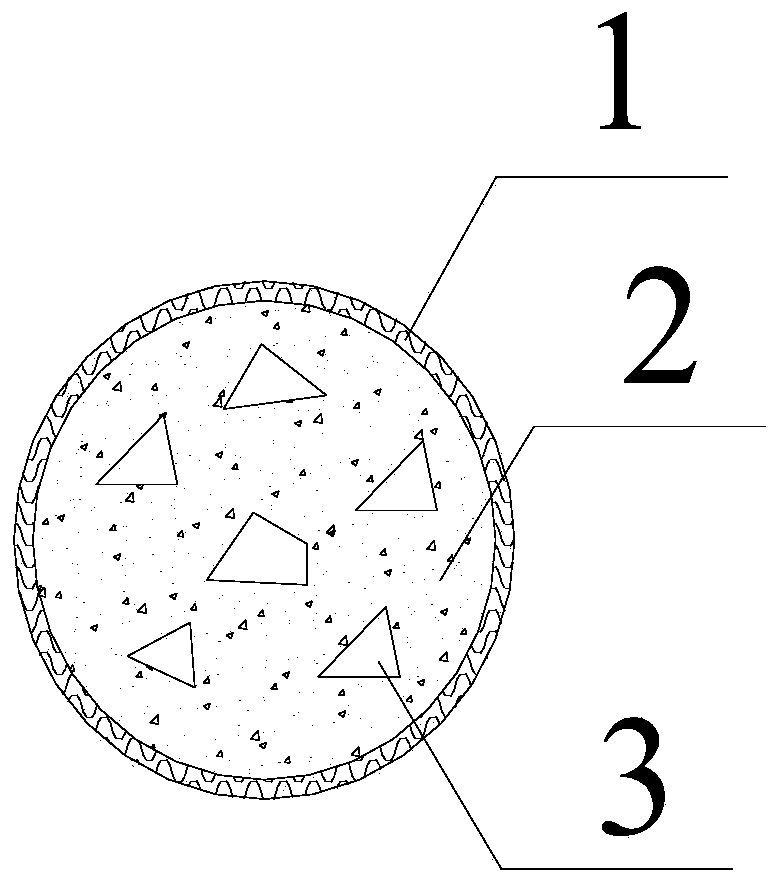

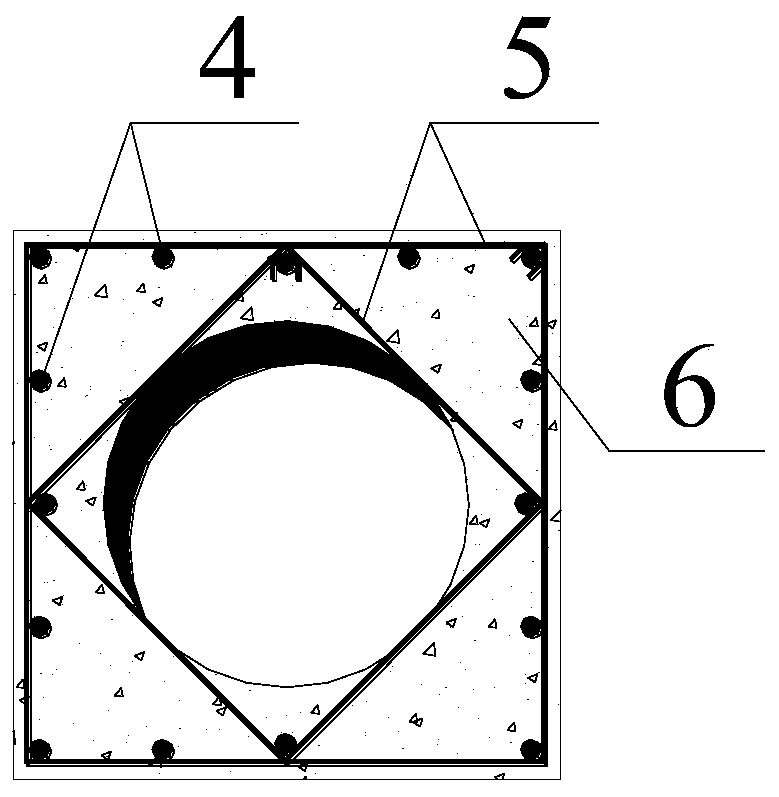

[0038] refer to figure 1 , figure 2 , image 3 and Figure 4 , this embodiment is a way of comprehensively utilizing waste concrete and seawater and sea sand with low energy consumption, and the composite components produced can be used for components such as columns, beams and supports; the steps are as follows:

[0039] (1) Crushing, removing impurities and grading the collected waste concrete into recycled coarse aggregate and large waste concrete blocks 3, wherein the recycled coarse aggregate should meet the requirements of the current national standards, and the large waste concrete blocks 3 The maximum external dimension shall not exceed 2 / 3 of the short side dimension or diameter of the LC-SSRC hybrid component constrained by the pipe; the quality requirements of sea sand particle gradation, mud content, mud content, firmness index and organic matter content shall meet Requirements of relevant national norms;

[0040] (2) According to the requirements of the requi...

Embodiment 2

[0045] refer to figure 1 , figure 2 , Figure 5 and Figure 6, the difference between this embodiment and Embodiment 1 is that the shape of the peripheral cast-in-place part can be made into a circular section superimposed component according to the design requirements and engineering site conditions, so that after the construction is completed, it can be consistent with the construction party's intention and the surrounding environment. Match with architectural modeling etc.; The implementation steps of this embodiment are different from Embodiment 1 in the shape of reinforcement cage and peripheral formwork, others can be carried out according to Embodiment 1, according to this implementation finally obtain circular cross-section superimposed member, as Figure 6 shown.

Embodiment 3

[0047] combine figure 1 , figure 2 , Figure 7 and Figure 8 , this embodiment is another way of comprehensive utilization of waste concrete and seawater and sea sand with low energy consumption, and the composite components produced can be used for components such as walls and floors; the steps are as follows:

[0048] The fabrication of the tube-constrained LC-SSRC hybrid member in this embodiment is the same as that in Embodiment 1.

[0049] When this embodiment is a wall, the prefabricated pipe-constrained LC-SSRC hybrid member is transported to the construction site, hoisted in place, and the first steel bar 7 along one length direction of it is bound and the first steel bar 7 along its other length direction is bound. The second steel bar 8 and the tension bar 9 are used for template making. After cleaning up the sundries in the formwork and the LC-SSRC hybrid member constrained by the prefabricated pipes, pour concrete 6 and vibrate and compact it for curing, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com