Vine hanging control system and method for greenhouse planting

A control system and control method technology, applied in the field of agriculture, can solve the problems that the vine hanging technology cannot be effectively linked with the real-time data and the vine hanging device, and the vine crops are time-consuming and labor-intensive, so as to save manpower and time costs, shorten the maturity cycle, and improve yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The system and method for controlling hanging vines for greenhouse planting of the present invention will be described in detail below with reference to the accompanying drawings through specific embodiments.

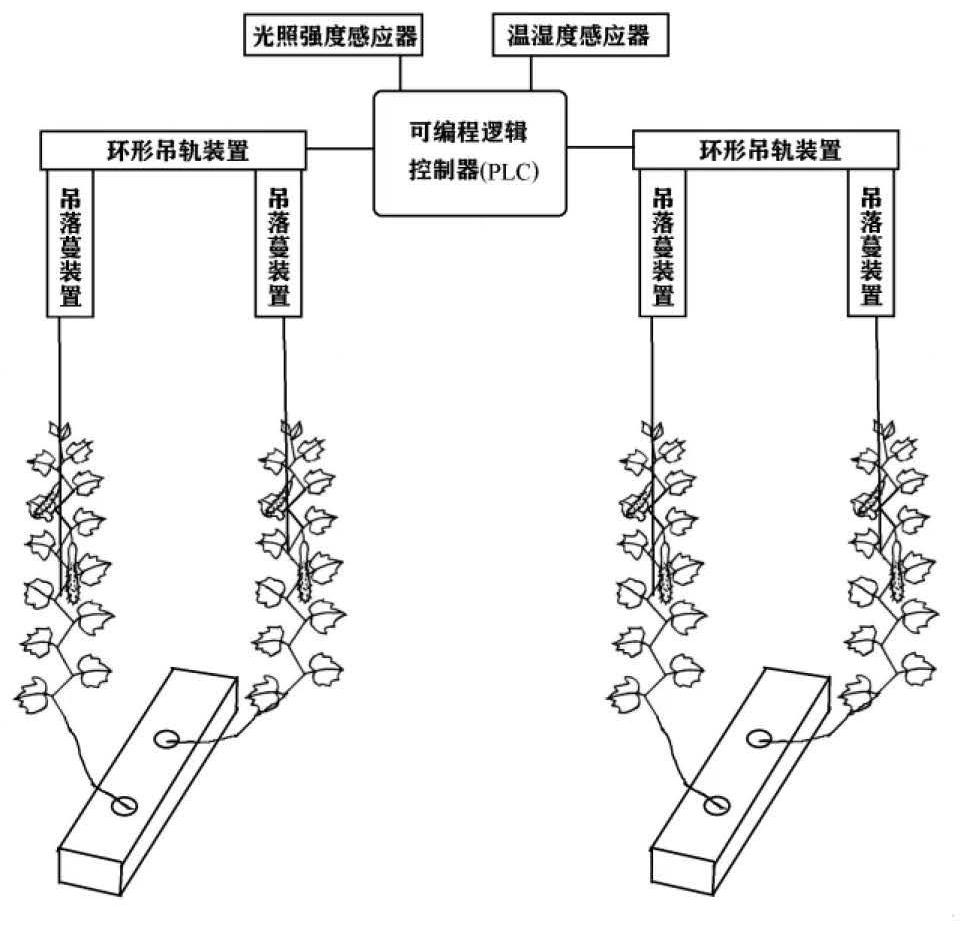

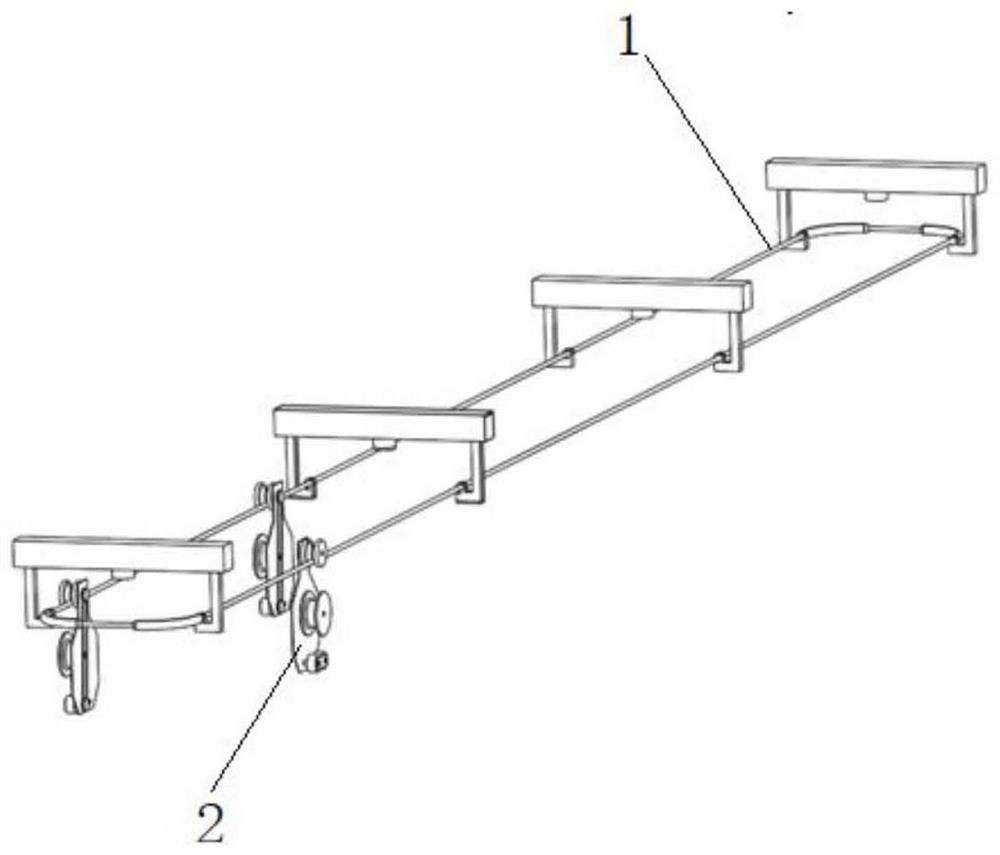

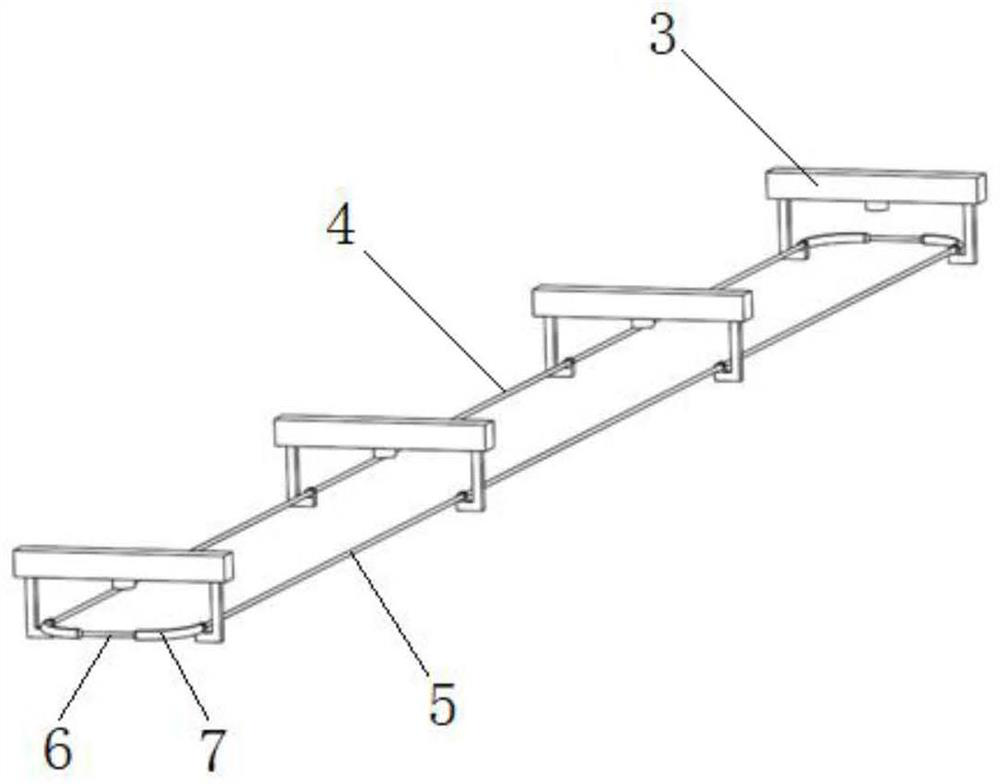

[0042] see Figure 1-2 , According to the present invention, a hanging vine control system for greenhouse planting mainly includes an annular hanging rail device 1, a hanging vine device 2 and an automatic control device. Among them, the hanging vine device 2 is suspended on the annular hanging rail device 1 for lowering the vine rope and translation of the device. The automatic control device includes an environment monitoring module, an information transmission module and a central control module. The environmental monitoring module includes a temperature and humidity sensor and a light intensity sensor. The temperature and humidity sensors are located in the upper part of the high and high school plants on both sides of the greenhouse, and the light intensit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com