Yellow tea and preparation process thereof

A production process and technology of yellow tea, which is applied in the field of yellow tea and its production process, can solve the problems of yellow tea color and taste reduction, reduce the nutritional value of yellow tea, etc., achieve a clear fragrance, rich vitamin C, and fresh taste soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

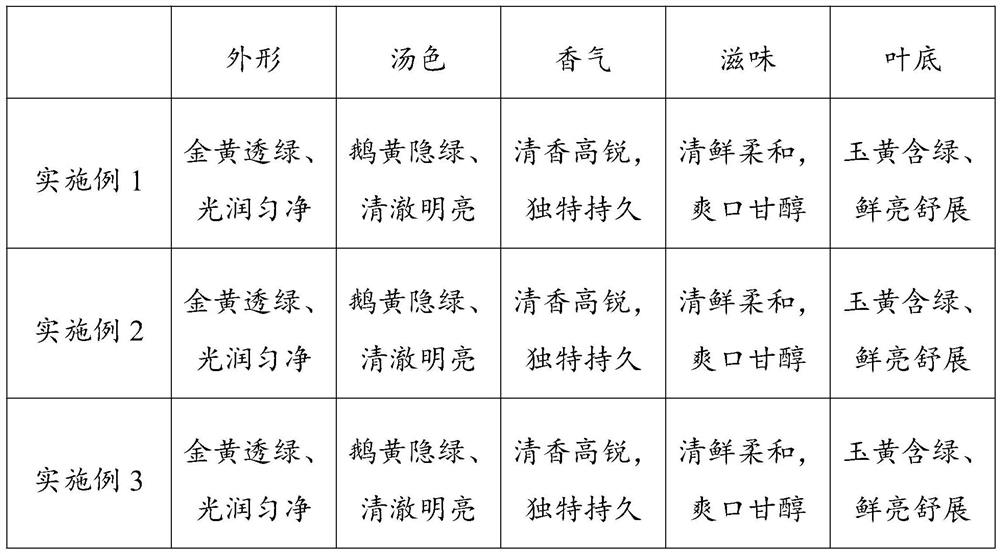

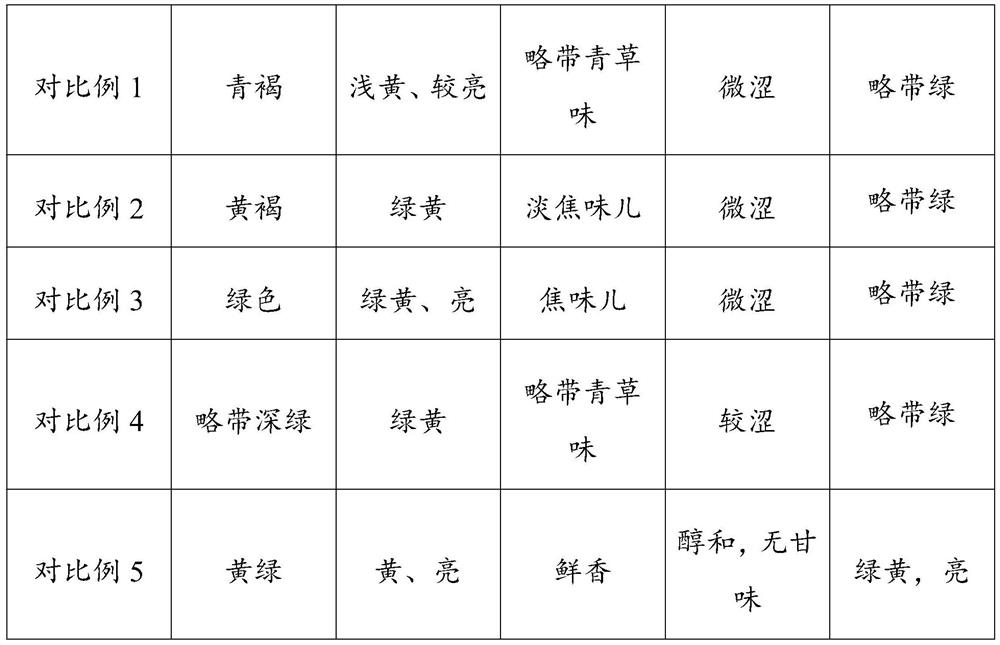

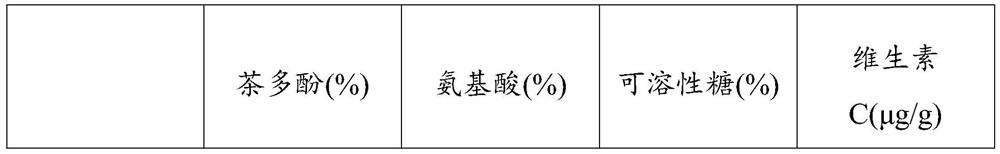

Examples

Embodiment 1

[0038] A kind of yellow tea production process, comprises the following steps:

[0039] S1. Picking fresh leaves: One month before and after Qingming, harvest "Zhonghuang No. 1" and "Zhonghuang No. 2" teas. No other impurities;

[0040] S1. Cooling: spread the fresh leaves thinly by 3cm, spread them for 5 hours, turn them lightly every 2 hours, until the water content of the fresh leaves reaches 65%, then they can enter the greening stage;

[0041] S2. Finishing: Before finishing, measure the temperature at 1 / 3 of the tea outlet and start throwing leaves when the temperature reaches 120°C. The amount of leaves thrown is 1.5kg / min. The tea is divided into one leaf and one bud, one bud and two leaves, and one bud and three leaves. Levels 1 to 3, start batches from level 1 to level 3; spread the fresh leaves 1cm thinly into the steam cleaning machine, and control the steam temperature at 150°C until the water content of fresh leaves is 50%;

[0042] S3. Drying: adopt low-temper...

Embodiment 2

[0047] A kind of yellow tea production process, comprises the following steps:

[0048] S1. Picking fresh leaves: One month before and after Qingming, harvest "Zhonghuang No. 1" and "Zhonghuang No. 2" teas. No other impurities;

[0049] S1. Cooling: spread the fresh leaves thinly by 3 cm, spread them for 7 hours, turn them lightly every 2 hours, and mix them gently until the water content of the fresh leaves reaches 70%, then it can enter the greening stage;

[0050] S2. Finishing: Before finishing, measure the temperature at 1 / 3 of the tea outlet and start throwing leaves when the temperature reaches 120°C. The amount of leaves thrown is 1.5kg / min. The tea is divided into one leaf and one bud, one bud and two leaves, and one bud and three leaves. Levels 1 to 3, starting from level 1 to level 3, start to kill in batches; spread the fresh leaves 1cm thinly into the steam killing machine, and control the steam temperature at 155°C until the water content of fresh leaves is 55%;...

Embodiment 3

[0056] A kind of yellow tea production process, comprises the following steps:

[0057] S1. Picking fresh leaves: One month before and after Qingming, harvest "Zhonghuang No. 1" and "Zhonghuang No. 2" teas. No other impurities;

[0058] S1. Cooling: spread the fresh leaves thinly by 3cm±0.5cm for 5-7 hours, gently turn and mix every 2 hours, until the water content of the fresh leaves reaches 65-70%, then it can start killing stage;

[0059] S2. Finishing: Before finishing, measure the temperature at 1 / 3 of the tea outlet and start throwing leaves when the temperature reaches 120°C. The amount of leaves thrown is 1.5kg / min. The tea is divided into one leaf and one bud, one bud and two leaves, and one bud and three leaves. From level 1 to level 3, degreening is carried out in batches from level 1 to level 3; the temperature of the steam degreening machine is adjusted by controlling the temperature of the boiler; the fresh leaves are thinly spread 1 cm into the steam degreenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com