A method for preparing concrete that can self-report damage

A concrete and reporting technology, applied in the field of concrete structure health monitoring, can solve the problems of large detection position limitation, poor accuracy, inability to real-time in-situ detection, etc., and achieve the effect of increasing construction difficulty and simple construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

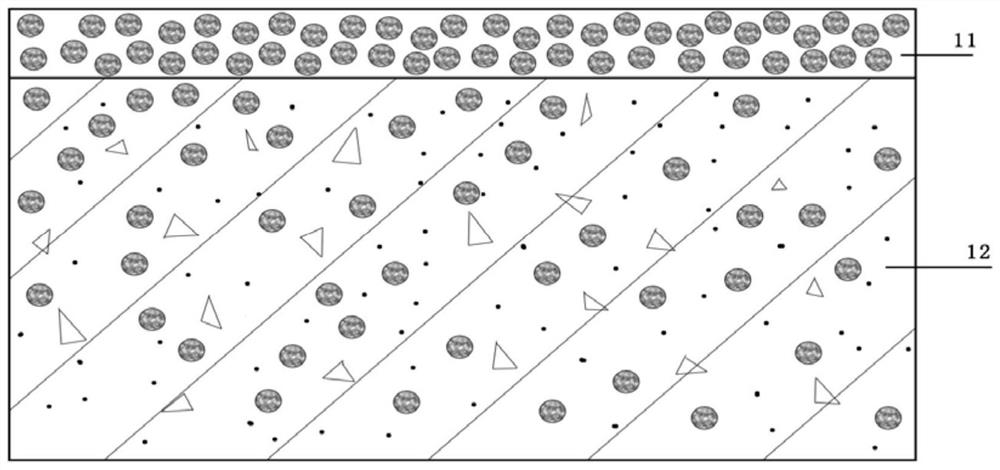

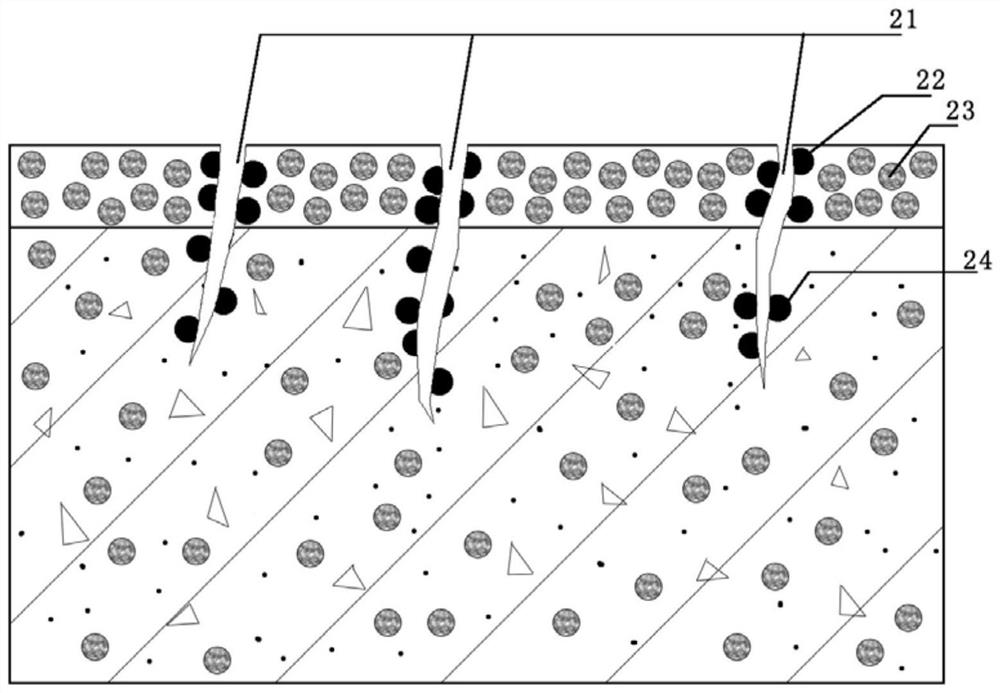

[0060] In conjunction with the accompanying drawings, the present invention proposes a method for preparing concrete that can self-report damage. The method combines visual sensing with concrete damage monitoring, and cracks appear when the color changes, which is intuitive and clear (especially when monitoring structures that do not allow cracks) more convenient); and reduce the difficulty of construction, the optical fiber sensor needs to dig grooves on the concrete surface, while the self-reported damage concrete based on microcapsule technology introduced in the present invention is easy to prepare, can be completed before pouring, and some steps can be prefabricated; High sensitivity, as long as the concrete is damaged, it can be triggered regardless of cracking, abrasion, or crushing. The microcapsules are evenly distributed throughout the structure, and real-time in-situ monitoring can be realized in all parts of the structure.

[0061] The present invention selects the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com