Polypropylene-basic magnesium sulfate whisker composite material for thin-wall automotive product

A technology of magnesium sulfate whiskers and composite materials, which is applied in the field of polymer materials, can solve problems such as not being able to meet the high rigidity of materials, and achieve the effects of strong rigidity, low density and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

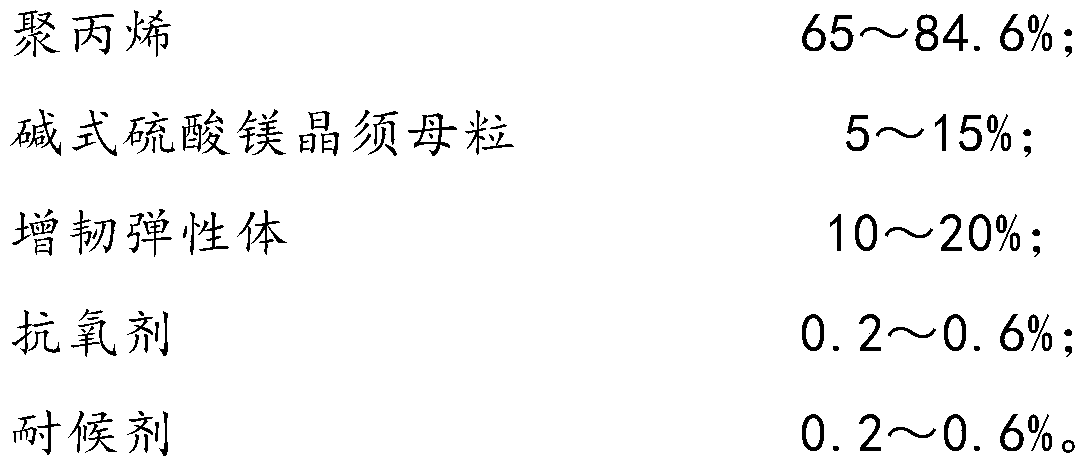

Method used

Image

Examples

Embodiment 1

[0026] Be the high flow polypropylene of 83.4 parts by weight, the elastomer of 10 parts, the basic magnesium sulfate whisker master batch of 6 parts (whisker active ingredient is 80%), 0.2 part of antioxidant A, 0.2 part of antioxidant Add agent B and 0.2 parts of weathering agent into the mixer and mix evenly. Wherein, the temperature of the mixer is 63° C., and the rotation speed of the mixer is 130 rpm, and then the mixed material is put into a twin-screw extruder for extrusion, cooling, granulation, and packing. The temperature of the extruder is 180°C, 195°C, 195°C, 190°C, 190°C, 190°C, 185°C, 185°C from the feeding section to the machine head, the screw speed is 180 rpm, and the screw length-to-diameter ratio It is 36:1.

Embodiment 2

[0032] The parts by weight are 76.9 parts of high flow polypropylene, 10 parts of elastomer, 12.5 parts of basic magnesium sulfate whisker masterbatch (whisker active ingredient is 80%), 0.2 part of antioxidant A, 0.2 part of antioxidant Add agent B and 0.2 parts of weathering agent into the mixer and mix evenly. Wherein, the temperature of the mixer is 63° C., and the rotation speed of the mixer is 130 rpm. Then put the mixed material into a twin-screw extruder for extrusion, cooling, granulation, and packaging. The temperature of the extruder is 180°C, 195°C, 195°C, 190°C, 190°C, 190°C, 185°C, 185°C from the feeding section to the machine head, the screw speed is 180 rpm, and the screw length-to-diameter ratio is 36:1.

Embodiment 3

[0044] Be the high flow polypropylene of 73.4 parts by weight, the elastomer of 20 parts, the basic magnesium sulfate whisker master batch of 6 parts (whisker active ingredient is 80%), 0.2 part of antioxidant A, 0.2 part of antioxidant Add agent B and 0.2 parts of weathering agent into the mixer and mix evenly. Wherein, the temperature of the mixer is 63° C., and the rotation speed of the mixer is 130 rpm. Then put the mixed material into a twin-screw extruder for extrusion, cooling, granulation, and packaging. The temperature of the extruder is 180°C, 195°C, 195°C, 190°C, 190°C, 190°C, 185°C, 185°C from the feeding section to the machine head, the screw speed is 180 rpm, and the screw length-to-diameter ratio is 36:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com