Light weight, high-strength and environmentally-friendly type nonmetallic sound barrier

A sound barrier and environment-friendly technology, applied in construction, noise absorption devices, etc., can solve problems such as inorganic fibers and perlite sound-absorbing boards, and achieve controllable production quality, reduce installation labor intensity, mechanical Excellent performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

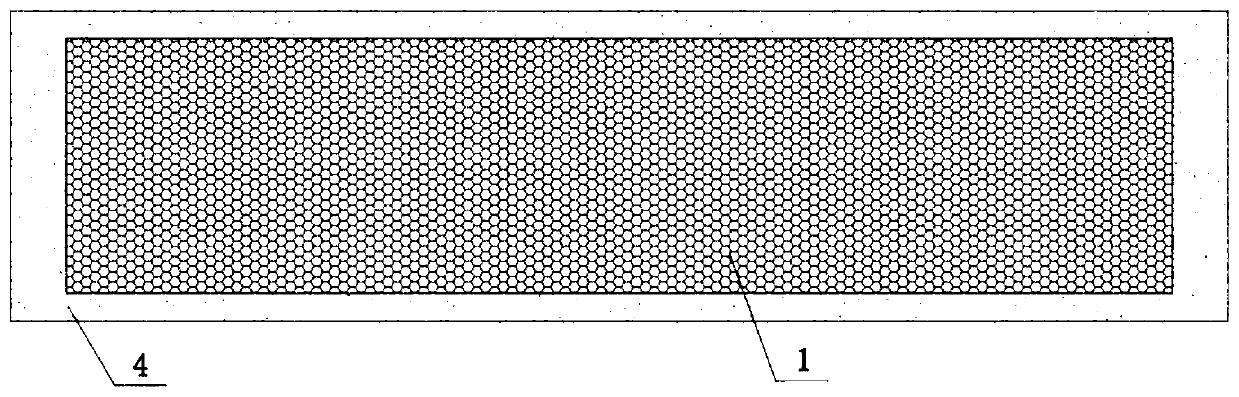

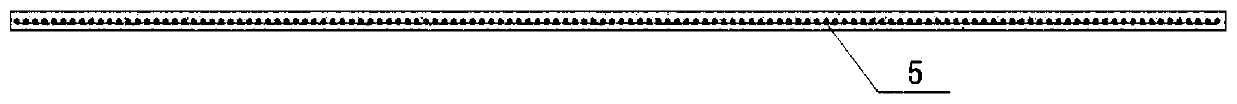

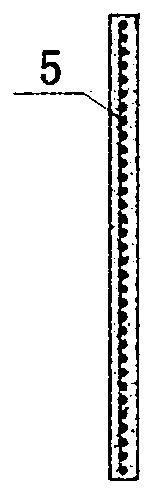

[0040] A light-weight, high-strength, environment-friendly non-metallic sound barrier, consisting of a sound-absorbing panel, a sound-insulating panel, and a fixing device; the fixing device is an H-shaped steel column, and a U-shaped groove is arranged in the H-shaped steel column. The limit block, the lower waist of the U-shaped groove is inserted between the web of the H-shaped steel column and the limit block, the upper opening is fixed with the web of the H-shaped steel column by bolts, and the H-shaped steel column is fixed on the edge of the bridge deck or road surface. Several microporous particle sound-absorbing panels and concrete sound-insulating panels are inserted between the columns to form a sound barrier. The contact parts between the sound-absorbing panel and the concrete sound-insulating panel, the H-shaped steel flange plate and the U-shaped groove are flexibly connected by rubber strips, and an air separation cavity is left between the microporous particle s...

Embodiment 2

[0054] It is basically the same as Example 1, except that the microporous particle sound-absorbing panel is equipped with a transverse reinforcing plate in the middle besides the reinforcing plate around it. The concrete sound insulation board and the microporous particle sound-absorbing panel have the same size. There is a rubber block in the middle to separate the concrete sound insulation board from the microporous particle sound absorption board. The contact part between the concrete sound insulation board and the microporous particle sound absorption board and the H-shaped steel flange plate is flexibly connected by a P-type rubber plate, and the sound absorption The distance between the board and the sound insulation board is 120mm.

[0055] The microporous particle sound-absorbing panel is made of 16 parts by weight of inorganic adhesive A, 80 parts of granular material, 0.5 part of water reducing agent, and 3.0 parts of water, and is poured with three layers of reinforc...

Embodiment 3

[0067] It is basically the same as Example 1, except that a sound-absorbing wedge structure is provided on the surface of the microporous particle sound-absorbing board, and the distance between the sound-absorbing board and the sound-insulating board is 100mm.

[0068] The microporous particle sound-absorbing panel is made of 20 parts by weight of inorganic adhesive A, 75 parts of granular material, 0.4 part of water reducing agent, and 3.5 parts of water, and two layers of reinforced mesh are laid inside and poured, with a length of 1960mm. The width is 500mm and the thickness is 20mm; when the microporous particle sound-absorbing board is poured, 40 parts of inorganic adhesive B, 45 parts of aggregate, 2.5 parts of water reducing agent, 6 parts of fiber material and 6 parts of water are used as reinforcement boards to pour together forming. According to the appearance, it is necessary to add additives such as pigments to ensure that the sound-absorbing panels have different...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com