LED flame lamp adopting flame light-emitting assemblies on both sides

A technology of light-emitting components and LED lamp beads, which is applied in the field of LED flame lamps and lighting fixtures, can solve problems such as unfavorable automatic production, poor damage, and complex component structures, so as to save labor and materials, improve production efficiency, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

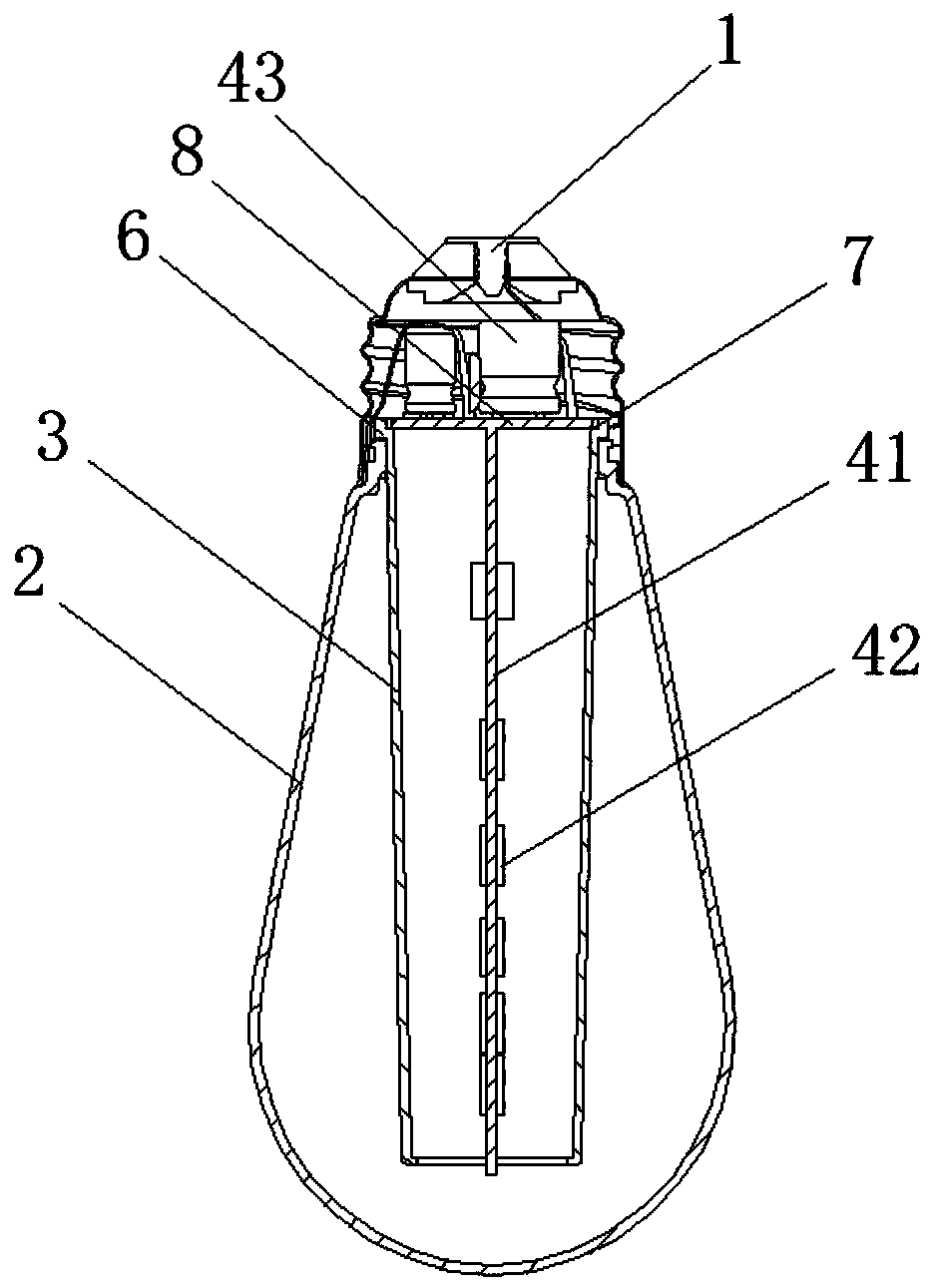

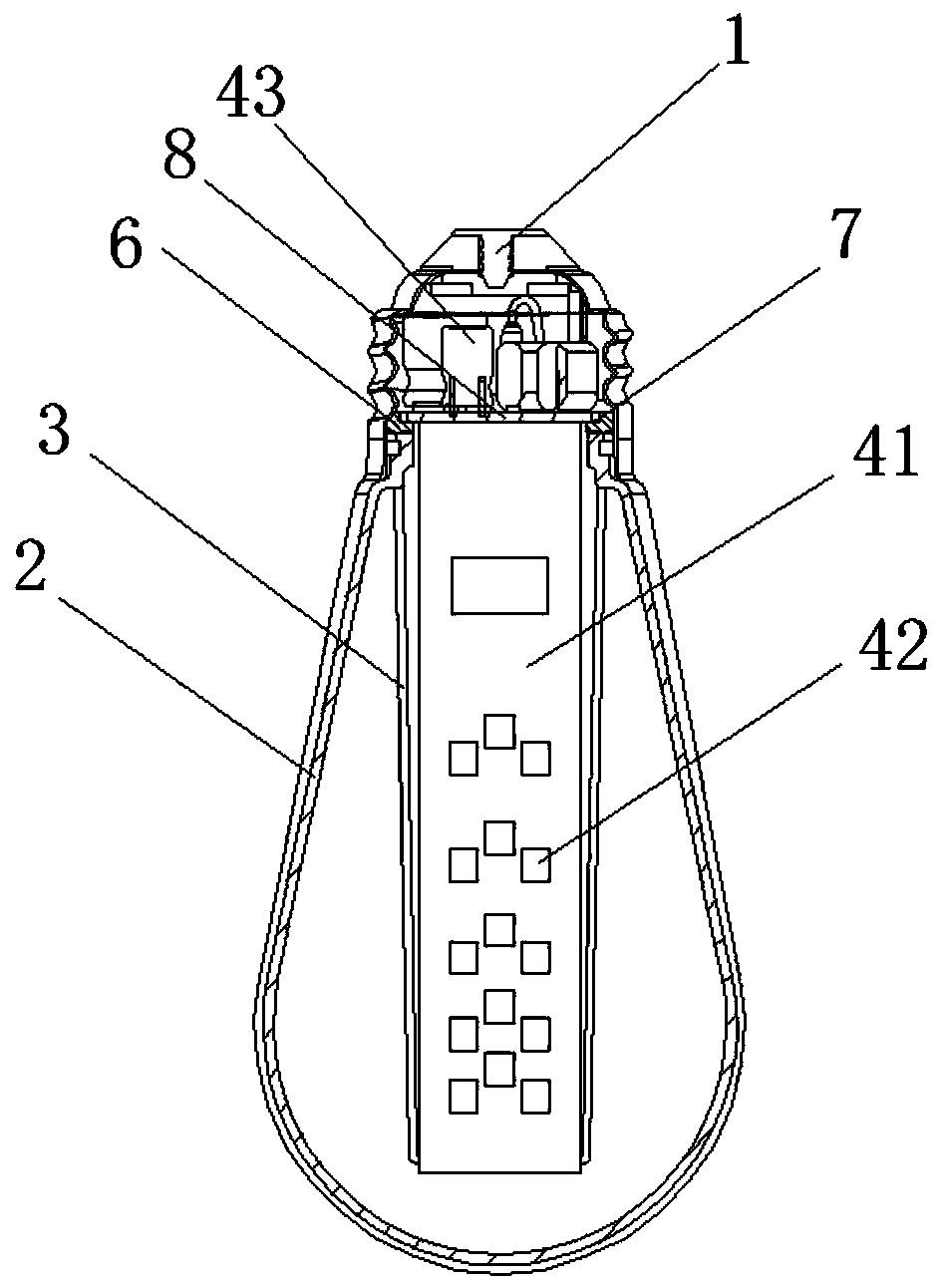

[0032] refer to figure 1 and figure 2 , the present invention is an LED flame lamp using a double-sided flame light-emitting component, including a lamp base 1, a bulb shell 2, a light guide tube 3 and a flame light source plate 4, the inner wall of the lamp base 1 is provided with a bulb shell 2, and the inside of the bulb shell 2 A light guide tube 3 is provided, and a flame light source board 4 is arranged inside the light guide tube 3. The flame light source board 4 includes a double-sided circuit board 41, LED lamp beads 42 and a driving power supply 43. The front and back sides of the double-sided circuit board 41 are welded. There are LED lamp beads 42, and the LED lamp beads 42 and the driving power supply 43 on the flame light source board 4 are respectively welded to two circuit boards, which are split structure flame light source boards, split structure flame light source boards, and double-sided circuit boards 41 are welded with LED lamp beads, the top of the dou...

Embodiment 2

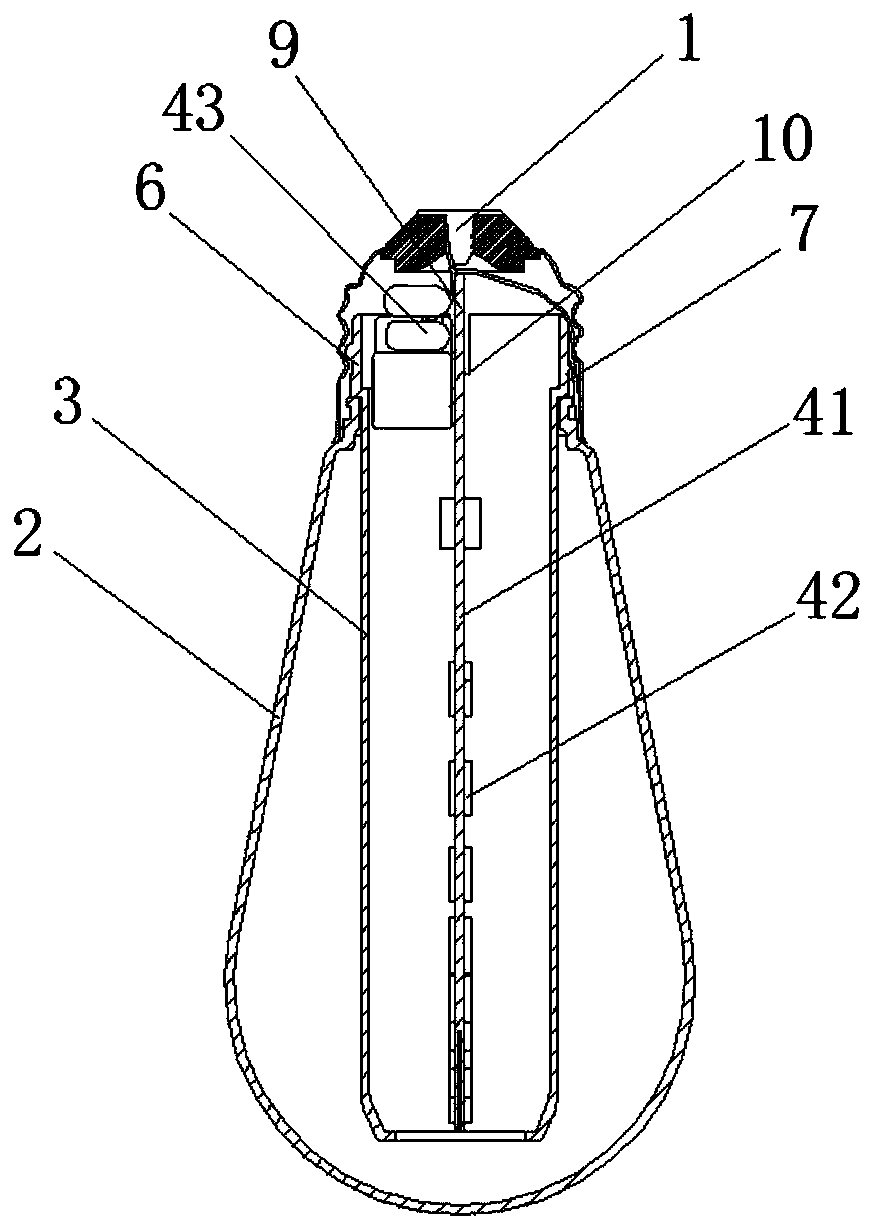

[0034] refer to image 3 , Figure 4 , Figure 5 and Figure 6 In this embodiment, on the basis of the first embodiment, the split structure of the first embodiment is changed into a T-shaped integrated structure. The LED lamp bead 42 and the driving power supply 43 are welded on the same double-sided circuit substrate 41, and the driving power supply 43 Lugs 9 are provided outward on both sides of the end of the double-sided circuit board 41. The double-sided circuit board 41 has a T-shaped structure. The lugs 9 are embedded in the slot 10 of the light guide tube 3 and fixed. One end and the center hole of one end of the light guide tube 3 are inscribed and clamped. The bulb shell 2 is made of plastic material. The top of the light guide tube 3 can be provided with external threads or not, which can make the structure of the LED bulb or lamp simpler and more optimized. Improve assembly efficiency, reduce manual labor, and its cost performance is more advantageous.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com