Method for improving quality of whole-plant wheat ensiling

A wheat and quality technology, applied in the field of plant silage, can solve problems such as unsatisfactory silage effect, and achieve the effects of accelerating fermentation speed, improving silage quality and reducing pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The whole wheat plant is harvested between the milk ripening stage and the wax ripening stage. After harvesting, the whole wheat plant is cut to a length of 2 cm. The water content of the whole wheat plant is 65%, and the dry matter content is 35%.

[0028] Mix the whole wheat with Lactobacillus plantarum and molasses evenly, put it into a polyethylene bag, seal it with a vacuum sealing machine, and silage it at room temperature in the dark for 45 days after sealing.

[0029] The capacity of the polyethylene bag is 250g, the amount of Lactobacillus plantarum added is 0.04‰ of the whole wheat plant, and the effective bacteria content in Lactobacillus plantarum is 4×10 10 More than CFU / g;

[0030] The amount of molasses added is 2% of the whole plant wheat, the sugar content of molasses is 50.43%, and the crude protein content is 9.24%;

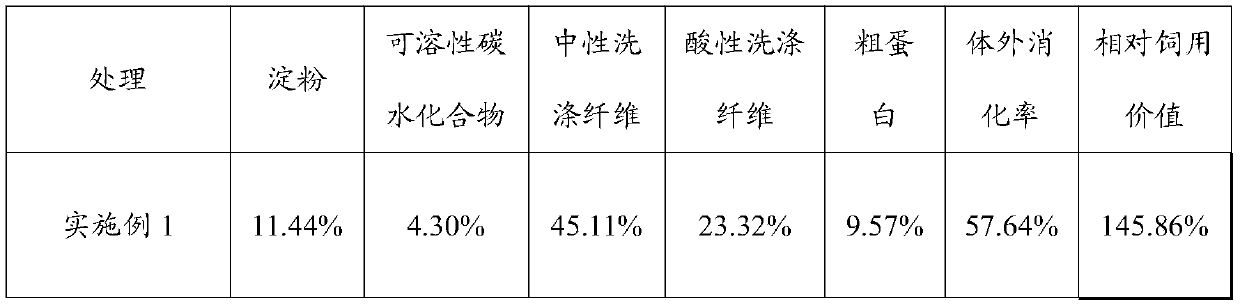

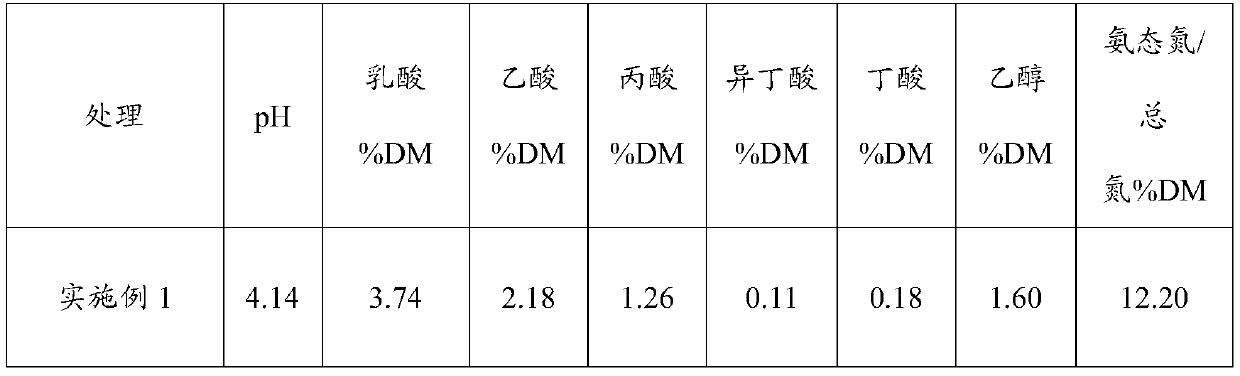

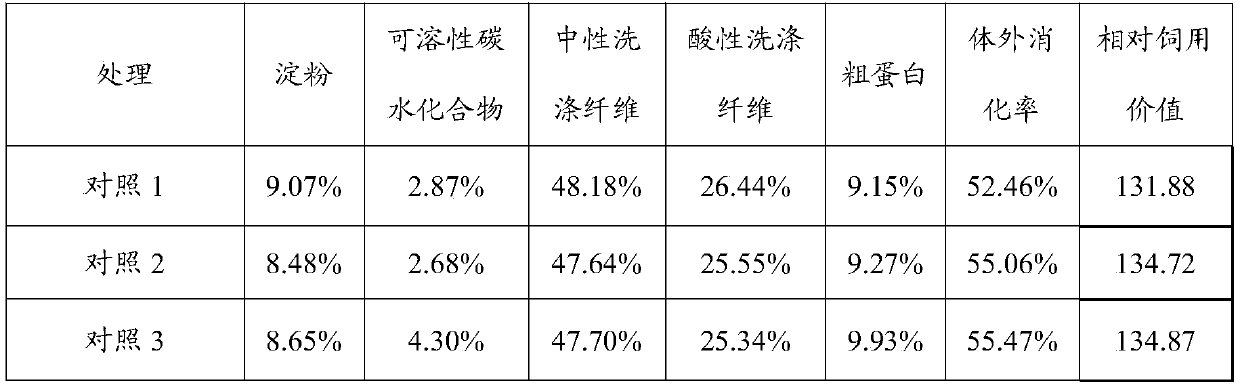

[0031] After the silage was finished, the silage was tested, and the results are shown in Tables 1-3.

[0032] Table 1 Feed ingredien...

Embodiment 2

[0049] The whole wheat plant is harvested between the milk ripening stage and the wax ripening stage. After harvesting, the whole wheat plant is cut to a length of 3 cm. The water content of the whole wheat plant is 72%, and the dry matter content is 28%.

[0050] Mix the whole wheat with Lactobacillus plantarum and molasses evenly, put it into a polyethylene bag, seal it with a vacuum sealing machine, and silage it at room temperature in the dark for 50 days after sealing.

[0051] The capacity of the polyethylene bag is 250g, the amount of Lactobacillus plantarum added is 0.04‰ of the whole wheat plant, and the effective bacteria content in Lactobacillus plantarum is 4×10 10 More than CFU / g;

[0052] The amount of molasses added is 1% of the whole plant wheat, the sugar content of molasses is 50.43%, and the crude protein content is 9.24%;

[0053] After the silage was finished, the silage was tested, and the results are shown in Tables 7-9.

[0054] Table 7 Feed ingredien...

Embodiment 3

[0071] The whole wheat plant is harvested between the milk ripening stage and the wax ripening stage. After harvesting, the whole wheat plant is cut to a length of 3 cm. The water content of the whole wheat plant is 70% and the dry matter content is 30%.

[0072] Mix the whole wheat with Lactobacillus plantarum and molasses evenly, put it into a polyethylene bag, seal it with a vacuum sealing machine, and silage it at room temperature in the dark for 45 days after sealing.

[0073] The capacity of the polyethylene bag is 250g, the amount of Lactobacillus plantarum added is 0.02‰ of the whole wheat plant, and the effective bacteria content in Lactobacillus plantarum is 4×10 10 More than CFU / g;

[0074] The amount of molasses added is 2% of the whole plant wheat, the sugar content of molasses is 50.43%, and the crude protein content is 9.24%;

[0075] After the silage is finished, the silage is tested, and the results are shown in Tables 13-15.

[0076] Table 13 Feed ingredien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective viable count | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com