Online purification device for aluminum alloy melt

A technology of aluminum alloy melt and melt, which is applied in the field of non-ferrous metallurgy, can solve the problems of inclusion blockage, shorten the life of the filter plate, and fail to solve the problems of the spoiler falling off and entering the melt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

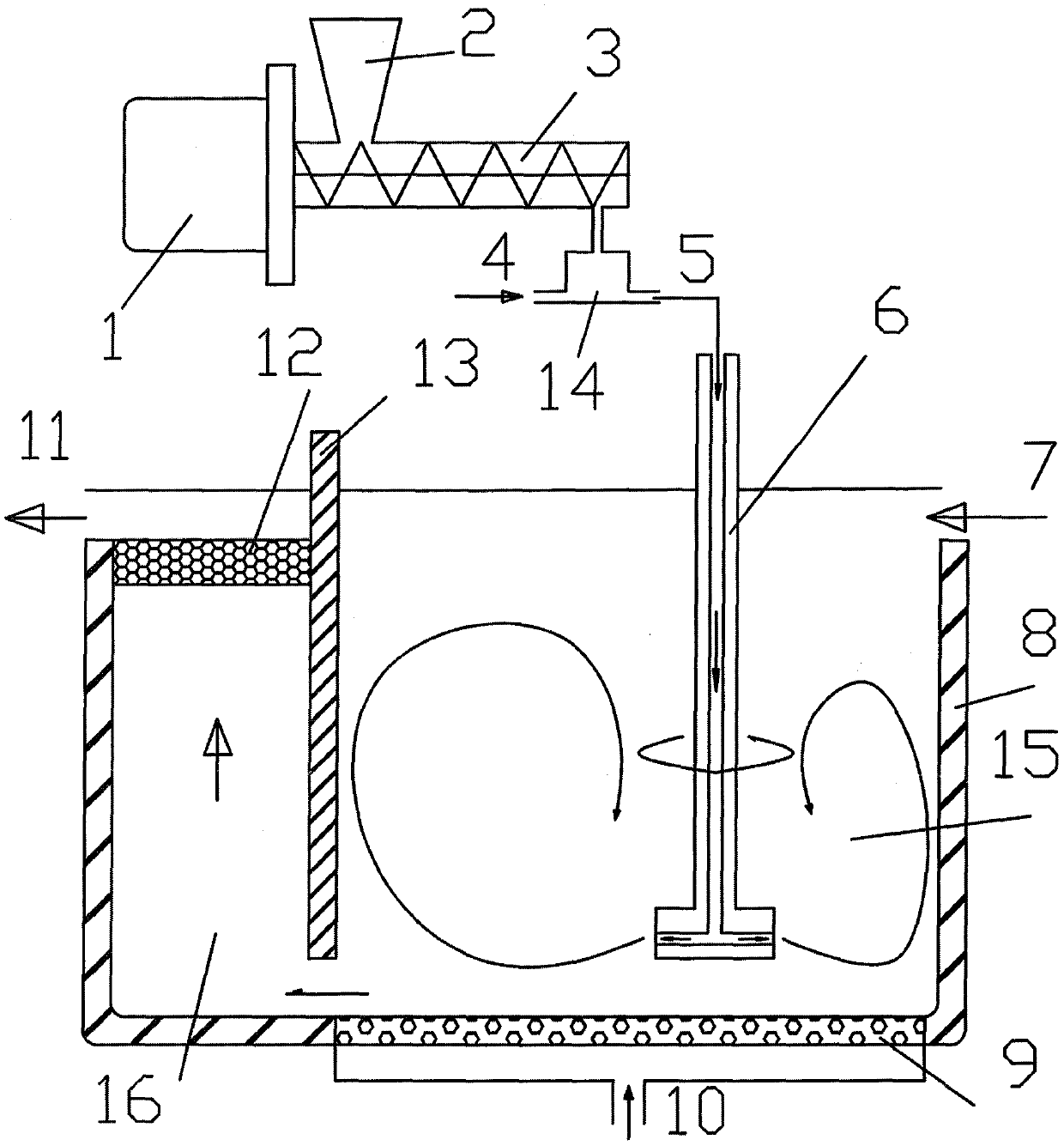

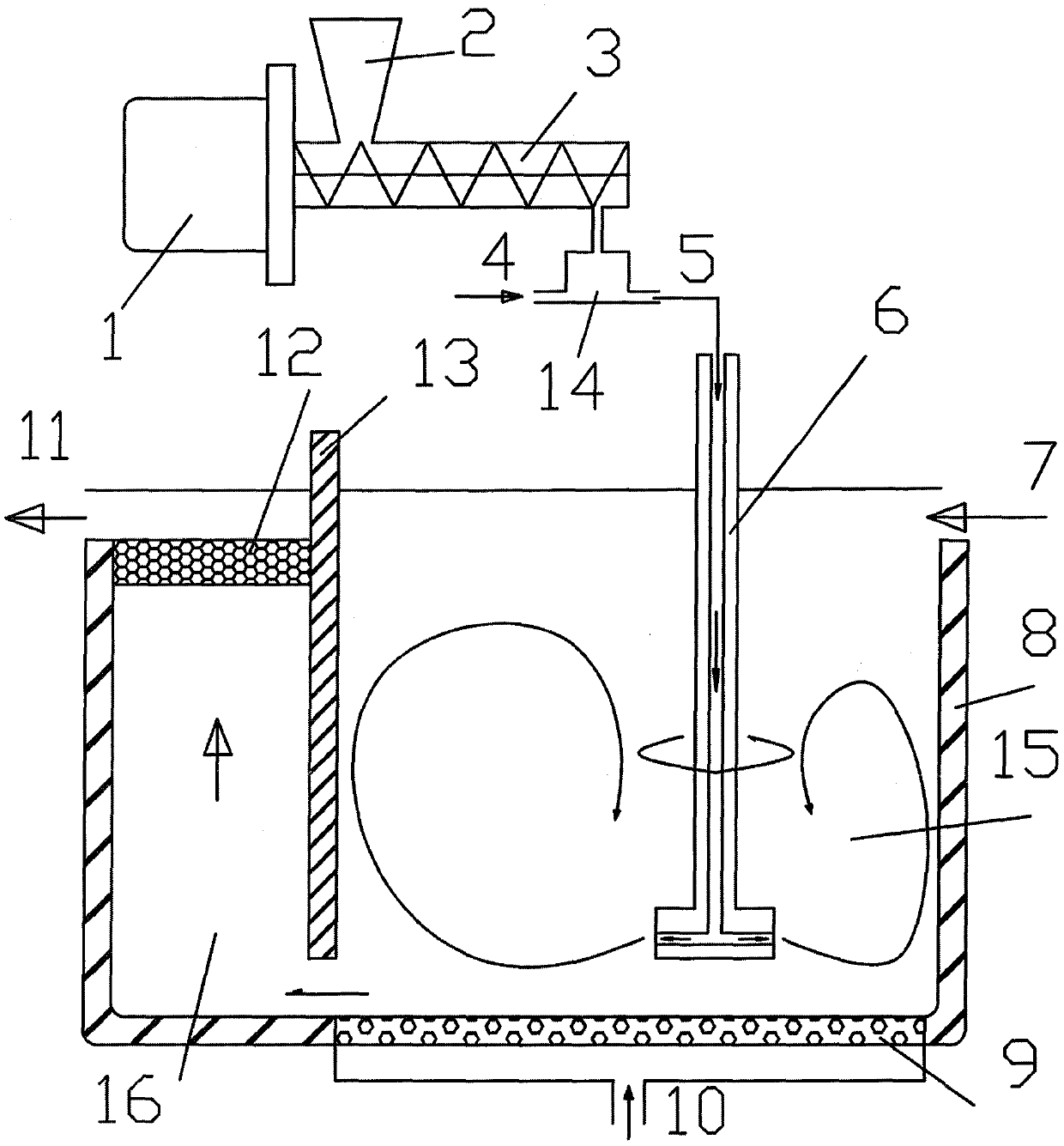

[0014] The aluminum melt flows into the purification chamber 15 from the melt inlet 7 from top to bottom at a flow rate of 400kg / h, and the temperature of the aluminum melt is 750°C; the diameter of the bottom of the purification chamber 15 is 400mm, and the liquid level height is 350mm; the dry refining agent is put into In the hopper 2, adjust the frequency conversion motor 1 to control the speed of the screw 3, so that the flow rate of the refining agent is 0.6kg / h, and the industrial argon gas with a purity of 99.9% is blown into the gas powder at an intake rate of 160ml / min and a gas pressure of 0.1MPa. Room 14, fully mixed to form gas-powder flow 5 into the offset rotary powder spraying device 6; the rotor diameter of the offset rotary powder spraying device 6 is 40 mm, 60 mm away from the bottom of the clean room, and the central axis of the rotor is offset from the center of the clean room 15 The distance is 100mm, the rotation speed of the rotor is 600rpm, the shearing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com