A method for anti-clogging of heat storage elements at cold end of air preheater by separating rings

An air preheater and anti-clogging technology, which is applied in combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problems of low flow rate of anti-clogging ash hot air, large temperature drop of hot air, and poor removal effect, etc. Achieve remarkable anti-blocking effect, low operating cost and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

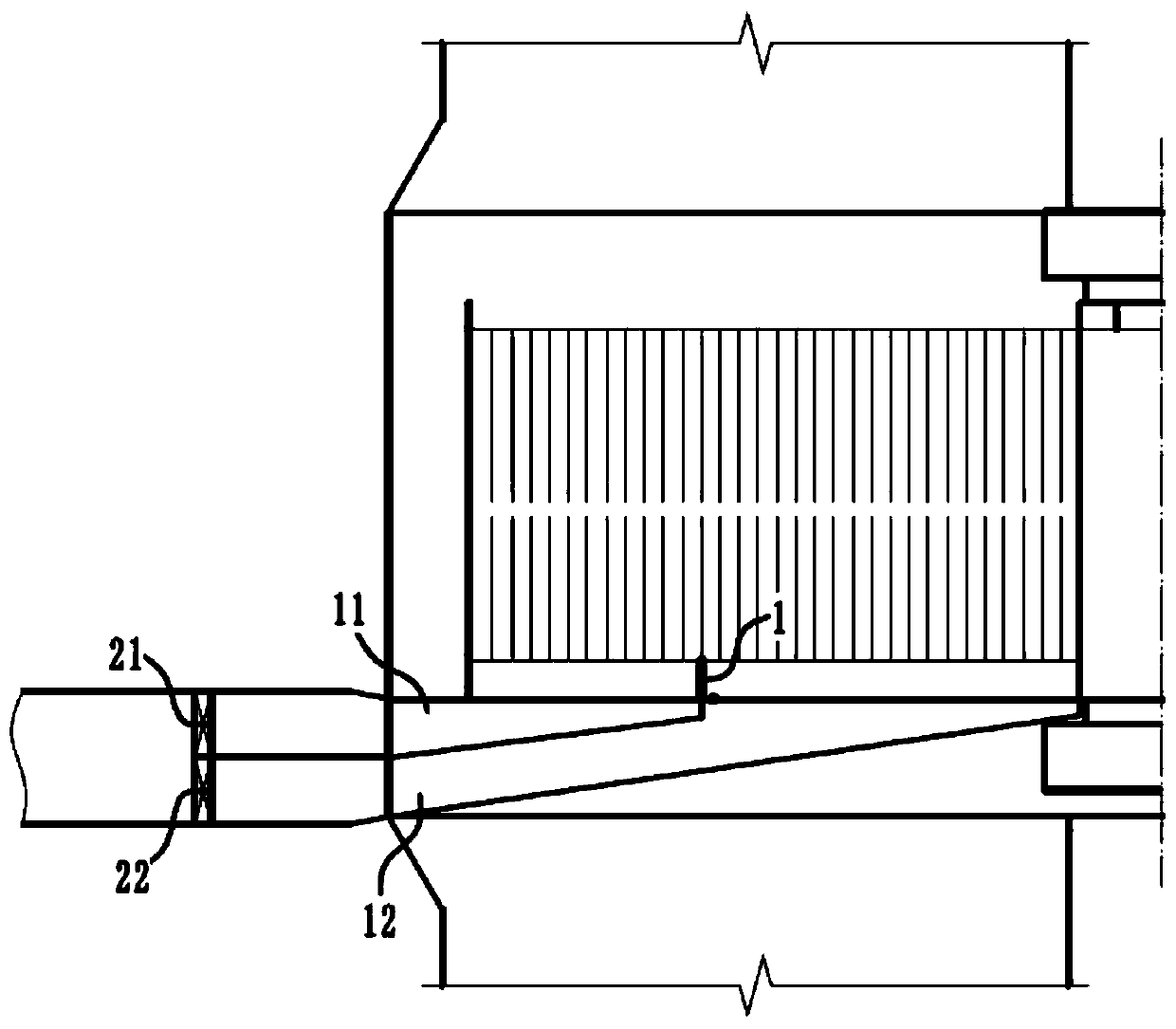

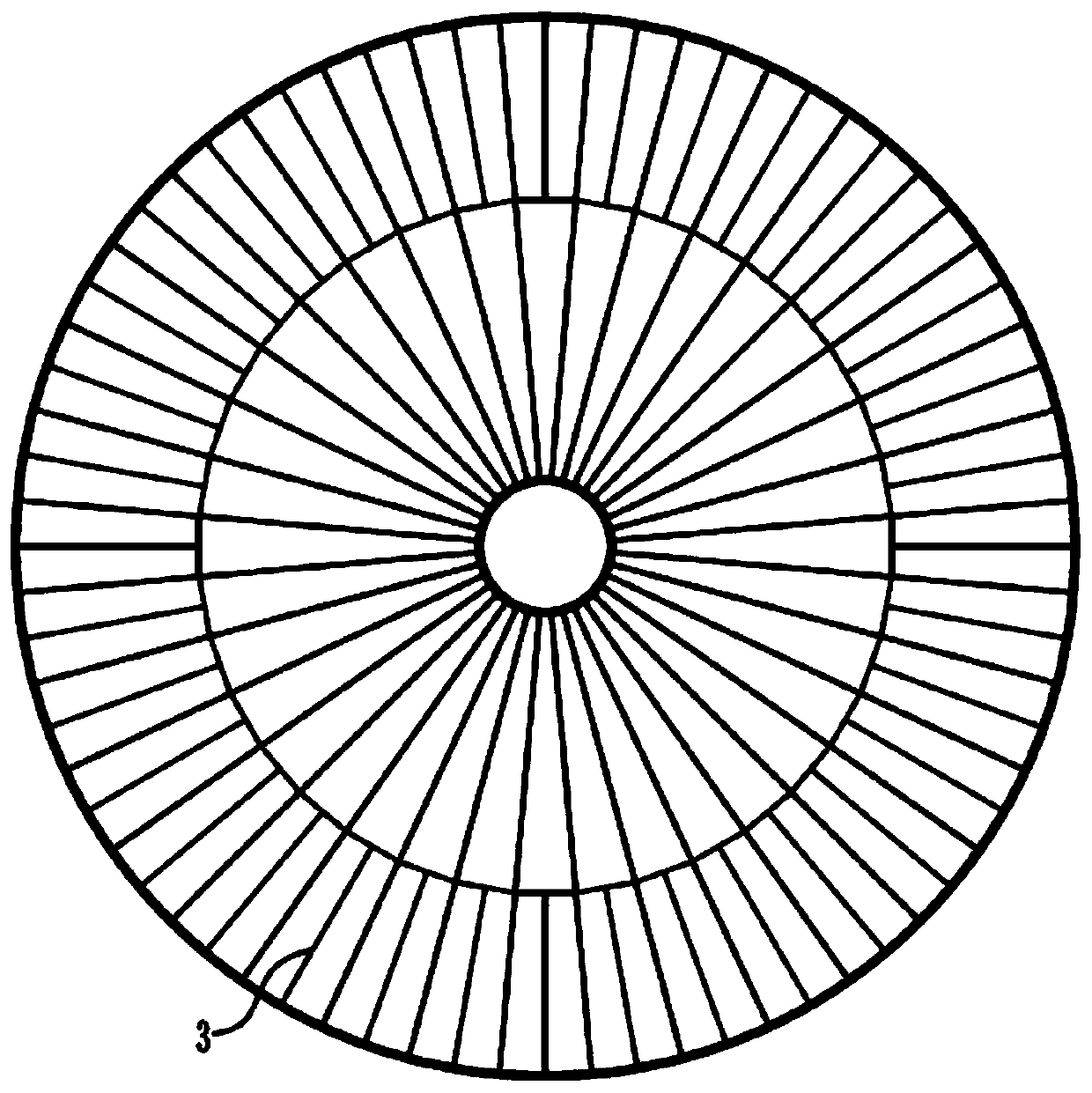

[0044] like Figure 1-2 As shown in the figure, a method of dividing the heat storage element at the cold end of the air preheater to prevent blockage. A first circumferential baffle with a circular structure is arranged on the cold end face of the rotor of the air preheater of the 300MW unit, and the cold end is separated. The end face is divided into 2 independent concentric annular air inlet channels. In order to improve the utilization efficiency of the anti-clogging ash hot air and reduce the leakage rate of the cold end of the anti-clogging ash bin, the rotor cold end face of the annular air inlet channel of the outermost ring is set. The intermediate radial partitions connected with the circumferential partitions, each rotor compartment corresponds to an intermediate radial partition, and the intermediate radial partitions are arranged along the angular bisector of the corresponding rotor compartment. Using the above technical measures, when When the air preheater rotor...

Embodiment 2

[0049] On the basis of Example 1, the following improvements were further made: in order to further improve the utilization efficiency of the anti-clogging ash hot air and reduce the leakage rate of the cold end of the anti-clogging ash warehouse, the above-mentioned circumferential partitions were provided with circumferential sealing sheets, and the diameter of the An intermediate radial seal is mounted to the bulkhead.

Embodiment 3

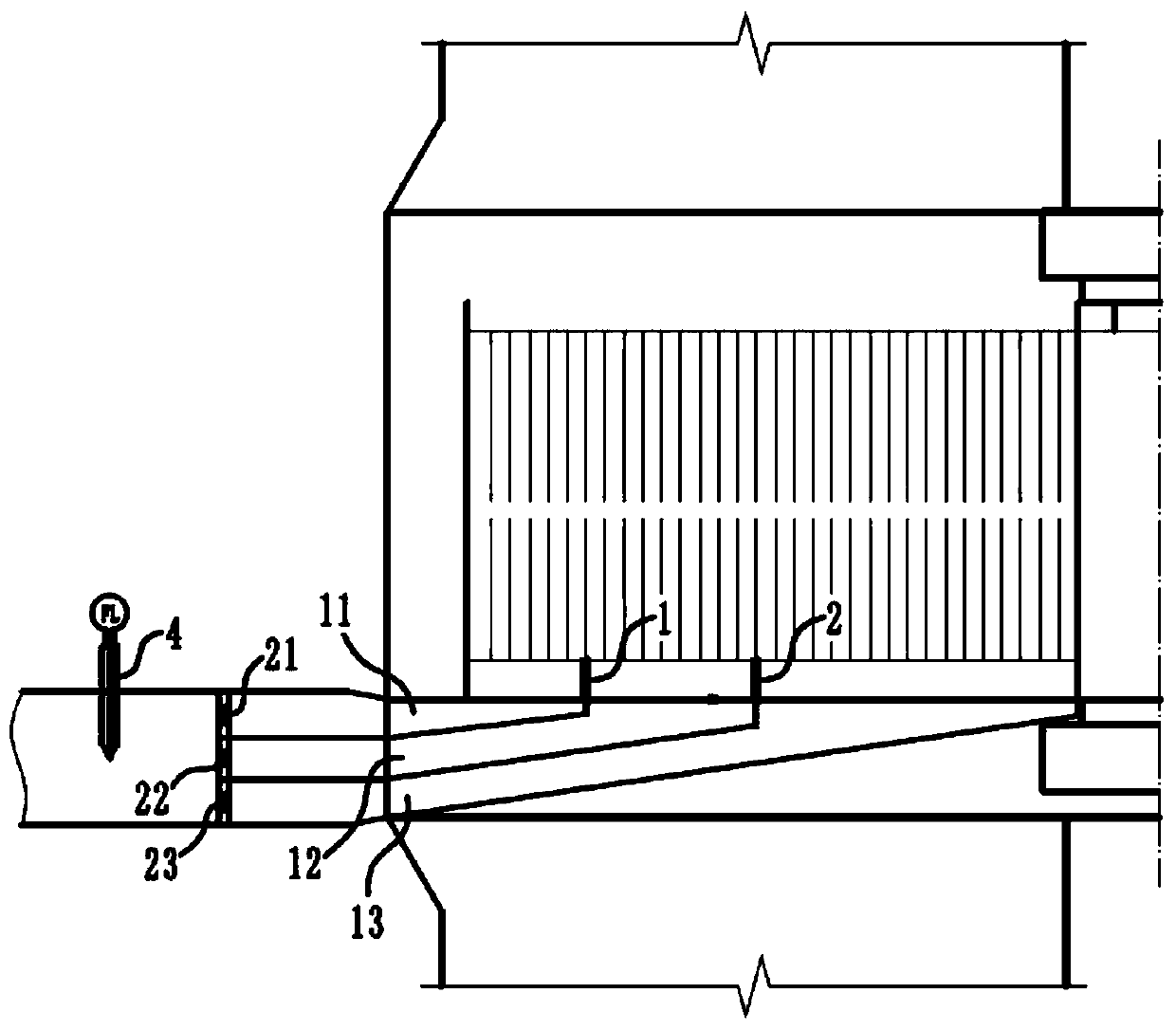

[0051] like Figure 3-4 As shown in the figure, a method for dividing the heat storage element at the cold end of an air preheater to prevent clogging, is to set two circumferential baffles with a ring structure on the cold end face of the rotor of the air preheater of a 600MW unit (respectively the first circle The end face of the cold end is divided into 3 independent coaxial annular air inlet channels; each annular air inlet channel is provided with an anti-blocking ash air chamber that communicates with it independently , that is, there are 3 anti-blocking gray air chambers, namely the first anti-blocking gray air chamber, the second anti-blocking gray air chamber and the third anti-blocking gray air chamber, the first anti-blocking gray air chamber, the second anti-blocking gray air chamber The upstream of the gray air chamber and the third anti-blocking gray air chamber all converge in the same anti-blocking gray air box, and an anti-blocking gray hot air flow meter is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com