Synthesis of ammonia with internal cooling circuit

An ammonia synthesis and circulating cooling technology, which is applied in ammonia compound, refrigeration and liquefaction, solidification and other directions, can solve the problems of limited cooling capacity of the internal cooling circuit, insufficient to meet the refrigeration needs of ammonia synthesis, and achieve the effect of improving cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

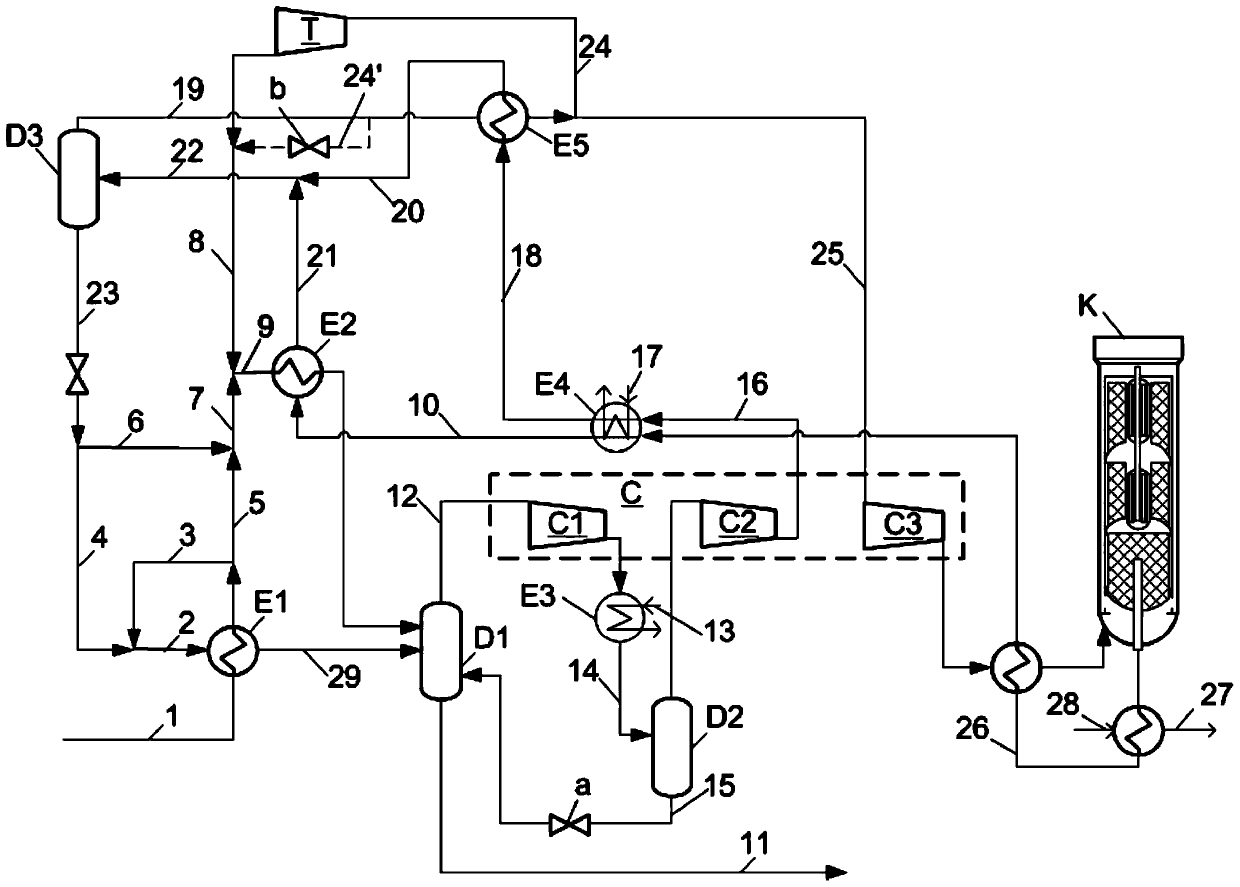

[0022] The fresh gas 1, which is present at a pressure between 20 and 30 bar(a) and mainly consists of hydrogen and nitrogen, is precooled in the precooler E1 by means of a coolant stream 2 composed of precooled fresh gas The first part 3 of 1 and liquid ammonia 4 are formed. In order to be able to fully utilize the cooling potential of the precooled fresh gas fraction 3, the amount of liquid ammonia 4 is determined in such a way that liquid ammonia is also present in the heated coolant stream 29 in the precooler E1, which is then separated off at low pressure. In device D1, the gas phase saturated with ammonia is separated.

[0023] In order to further reduce the temperature, the second part 5 of the precooled fresh gas 1 is also mixed with liquid ammonia 6 which, due to the pressure, temperature and quantity of the fresh gas 5, initially evaporates only a small part. In order to reduce the partial pressure of ammonia and to be able to evaporate larger quantities of ammonia,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com