Preparation method of patterned graphene gas sensitive sensor

A gas-sensing sensor and graphene technology, applied in the field of nano-sensors, can solve the problems of reduced graphene conductivity and difficult control of active groups, and achieve the effect of safety in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In order to solve the technical problems existing in the background technology, the present invention provides a method for preparing a patterned graphene gas sensor, that is, using an ultrashort pulse laser to pattern the complete graphene so that it has a specific topological structure, each The edge of each topological structure contains abundant dangling bonds and vacancy defects. Different defect types have different adsorption characteristics for different gases, so that different gases can be selectively sensed by designing different topological structures.

[0024] A kind of preparation method of patterned graphene gas sensor provided by the invention comprises the following steps:

[0025] Step 1. Put the copper foil sample loaded with graphene into the corrosion solution to etch the copper foil. After the copper in the sample is completely etched, transfer the graphene to deionized water and soak for 30 minutes. Repeat this process for 2-3 times, and then the ...

Embodiment 1

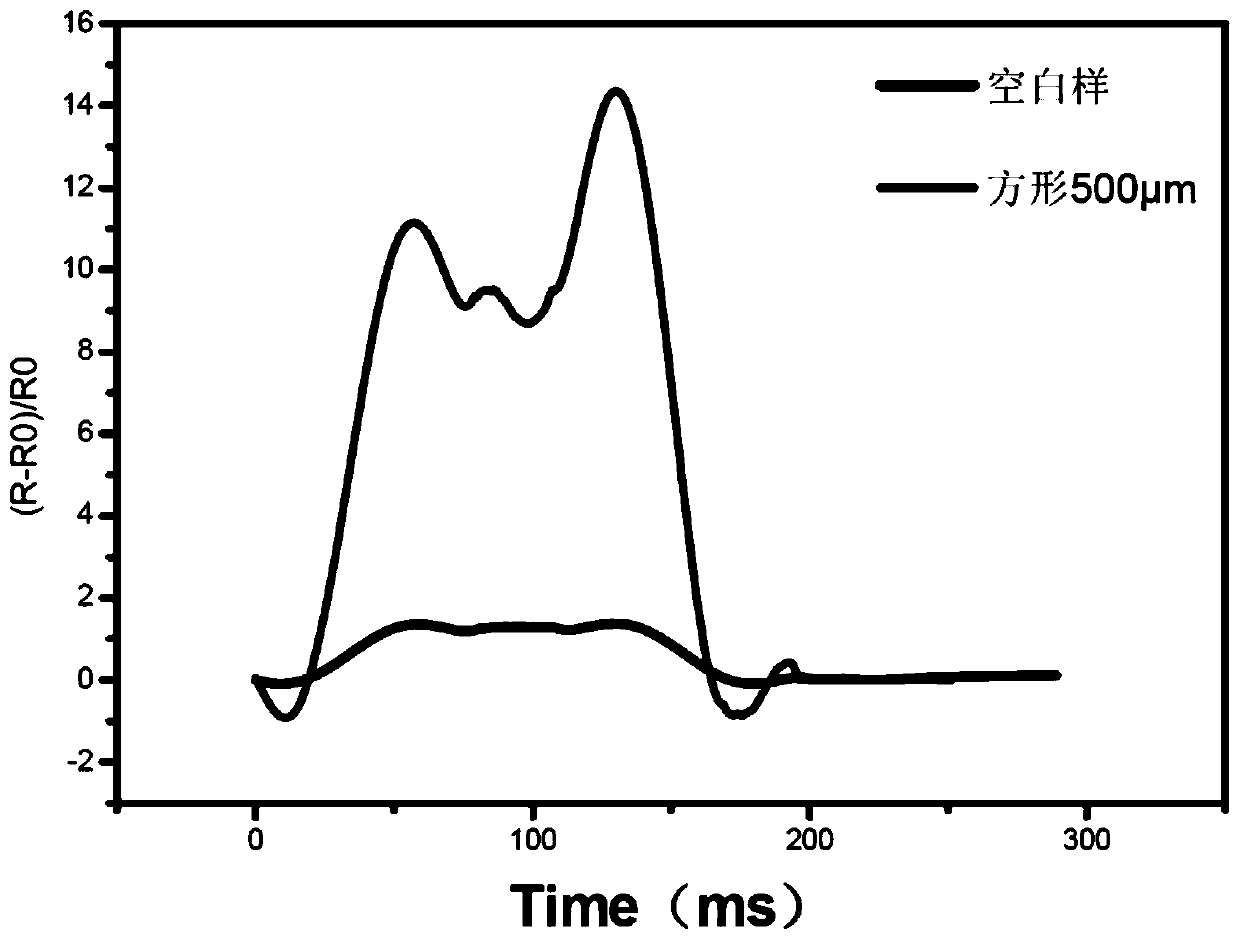

[0036] The graphene on polydimethylsiloxane (PDMS) was square-etched by a picosecond laser, and the adsorption and desorption performance of the patterned graphene sample on formaldehyde was detected.

[0037] The preparation steps are as follows:

[0038] (1) Preparation of transparent substrate PDMS

[0039] Mix DC184 and curing agent in a ratio of 10:1, stir well to generate air bubbles, put it into an ultrasonic cleaning instrument until the air bubbles completely disappear, pour it into a mold (150mm*150mm*10mm), and place it in an oven at 80°C for 2 hours to cure .

[0040] (2) Graphene transfer

[0041] Prepare FeCl with a concentration of 0.5mol / l 3 / HCl solution is used to etch copper, and the graphene / copper foil with an area of 10mm*10mm is cut and placed on the surface of the etching solution. After etching for 2 to 4 hours, transfer the graphene to deionized water with filter paper, soak for 30 minutes, then transfer to new deionized water, soak for 30 minutes...

Embodiment 2

[0047] The graphene on polydimethylsiloxane (PDMS) was square-etched by a femtosecond laser, and the adsorption and desorption performance of the patterned graphene sample on formaldehyde was detected.

[0048] The preparation steps are as follows:

[0049] (1) Preparation of transparent substrate PDMS

[0050] Mix DC184 and curing agent in a ratio of 10:1, stir well to generate air bubbles, put it into an ultrasonic cleaning instrument until the air bubbles completely disappear, pour it into a mold (150mm*150mm*10mm), and place it in an oven at 80°C for 2 hours to cure .

[0051] (2) Graphene transfer

[0052] Prepare FeCl with a concentration of 0.5mol / l 3 / HCl solution is used to etch copper, and the graphene / copper foil with an area of 10mm*10mm is cut and placed on the surface of the etching solution. After etching for 2 to 4 hours, transfer the graphene to deionized water with filter paper, soak for 30 minutes, then transfer to new deionized water, soak for 30 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com