Stereoscopic transition structure based on air gap waveguide in complex feed network

A technology of air gap and feed network, applied in the direction of waveguide, electrical components, waveguide type devices, etc., can solve the problems of no mention of insertion loss, no mention of, and reduction of insertion loss, and achieve low loss and convenient integration , The effect of reducing the requirements of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

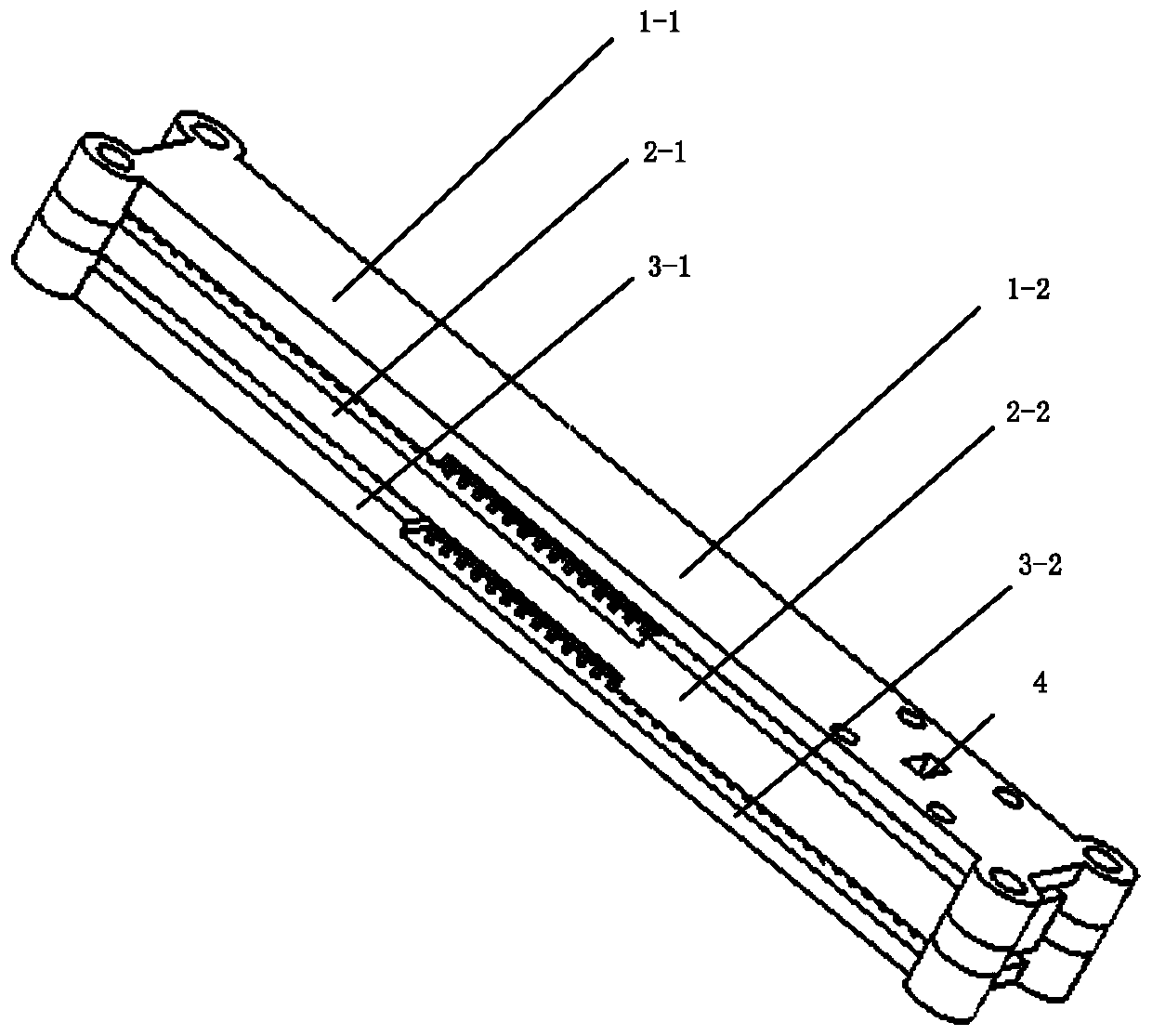

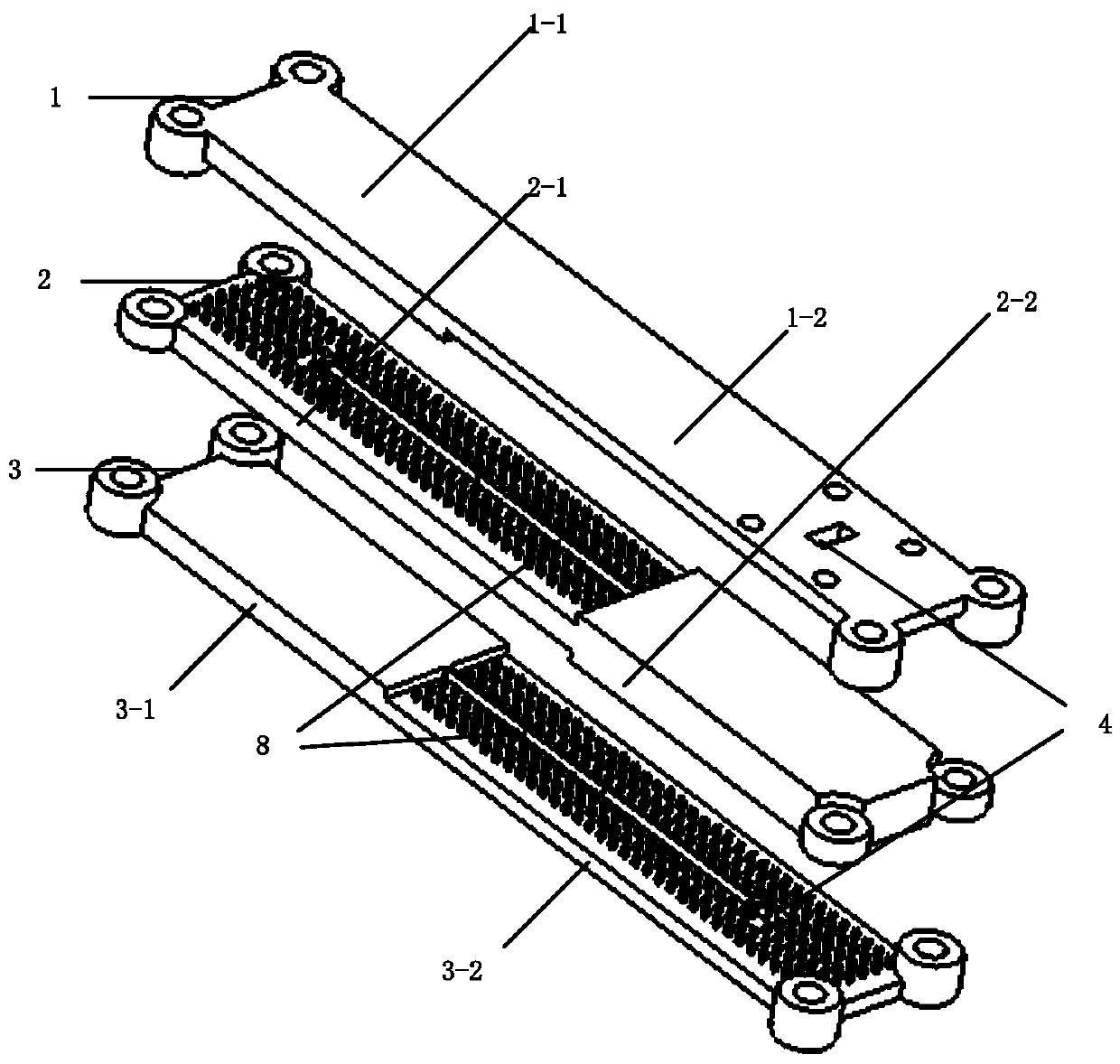

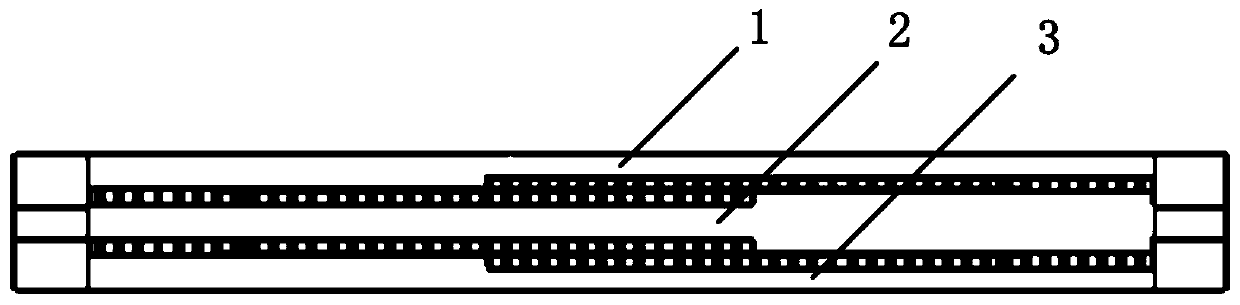

[0024] combine Figure 1 to Figure 5 , the three-dimensional transition structure based on the air gap waveguide in the complex feeding network of the present invention includes a top layer board 1, an intermediate layer board 2 and a bottom layer board 3, and the middle layer board 2 is arranged between the top layer board 1 and the bottom layer board 3, The three are connected by bolts.

[0025] The top board 1 includes a first ideal conductance wall 1-1, a first artificial magnetic conductance wall 1-2, a ridge-gap waveguide structure 8, an air-gap waveguide-coupling slot matching structure 7, a rectangular waveguide transition structure 4, and several electromagnetic bandgap EBGs Structure 5, one end of the first ideal conductance wall 1-1 is directly connected to one end of the first artificial magnetic conductance wall 1-2, the length of the first idea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com