Adsorbent material for removal of hydrogen sulfide

A technology of adsorbent and hydrogen sulfide, applied in other chemical processes, chemical instruments and methods, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

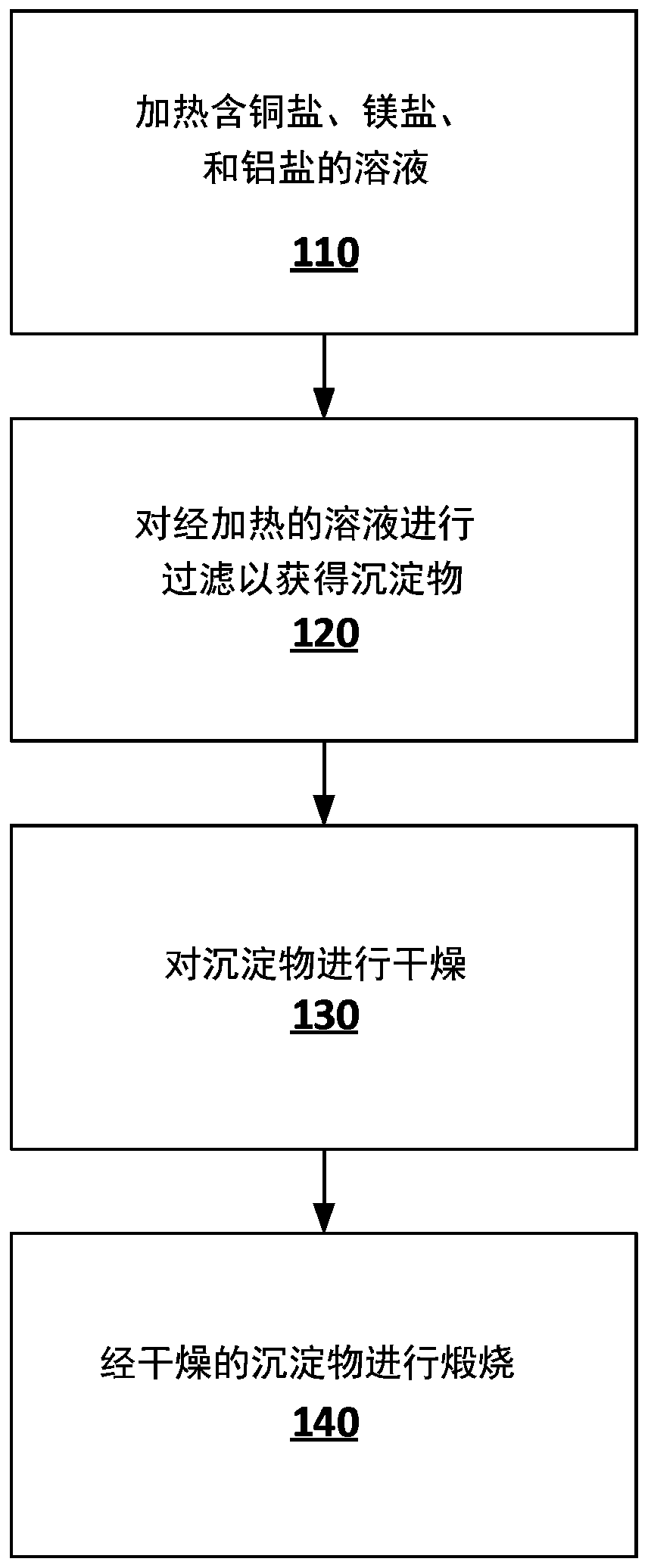

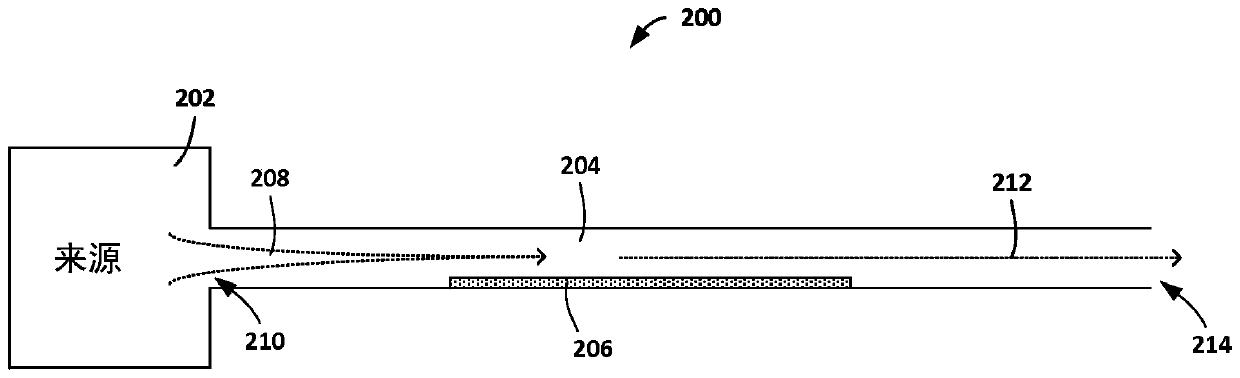

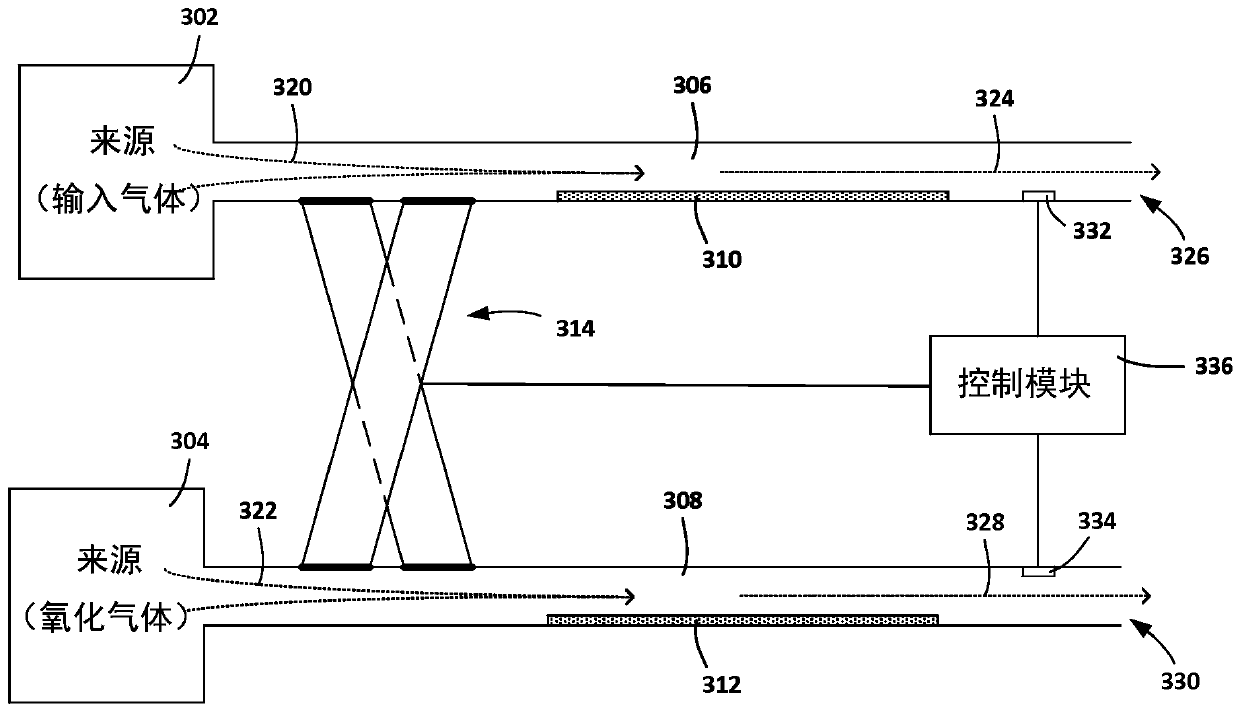

[0044] Materials are described herein for the adsorption of elemental sulfur from gases containing hydrogen sulfide. For example, embodiments of these materials may be used to remove or otherwise separate hydrogen sulfide gas from other types of gases. Embodiments of the sorbent material may include metal oxide mixtures of atomic copper (Cu), atomic magnesium (Mg), and atomic aluminum (Al) synthesized by co-precipitation. In some cases, the sorbent material exhibits a high and stable sulfur capacity (e.g., in the range of about 2 to 10 mmol sulfur per gram of sorbent or higher) such that when exposed to a gas source containing hydrogen sulfide, it remains Adsorb a lot of sulfur. Additionally, in some cases, the sorbent material may be regenerated after sorbing sulfur to remove some or all of the sorbed sulfur in the sorbent material. Thus, the sorbent material can adsorb large amounts of sulfur from the gas source and, after regeneration, can be reused to adsorb additional a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com