Film coating method of sterile paper box paper blank

A technology of paper base and film coating, which is applied in the field of film coating of aseptic carton paper base, which can solve the problems that the flatness of the film surface after film coating cannot be guaranteed, and easy to produce wrinkles and air bubbles, etc., and achieve moderate viscosity and good flatness , the effect of uniform contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

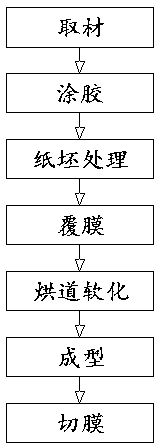

[0024] A method for covering a sterile carton blank, comprising the steps of:

[0025] A. Material collection: take BOPP specification film with a thickness of 15 μm, and corona treat the BOPP film;

[0026] B, gluing: use a gluing roller to coat a film surface of the BOPP film after the above-mentioned steps;

[0027] C. Paper base treatment: evenly apply leveling agent solution to the film-coated surface of the paper base;

[0028] D, film covering: the BOPP film after the step B treatment is covered on the film covering surface of the paper blank after the step C treatment;

[0029] E. Softening of the drying tunnel: Put the paper blank after the film-coating treatment in step D into a drying tunnel with a length of 150 cm, set the temperature of the drying tunnel at 60°C, and keep the atmospheric pressure in the drying tunnel at a low pressure state, so that the paper blank is covered with BOPP film high temperature softening;

[0030] F, forming: the paper base process...

Embodiment 2

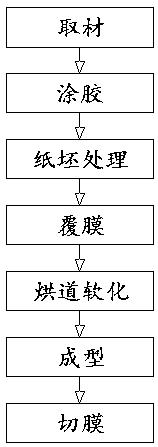

[0038] A method for covering a sterile carton blank, comprising the steps of:

[0039] A. Material collection: take BOPP specification film with a thickness of 15 μm, and corona treat the BOPP film;

[0040] B, gluing: use a gluing roller to coat a film surface of the BOPP film after the above-mentioned steps;

[0041] C. Paper base treatment: evenly apply leveling agent solution to the film-coated surface of the paper base;

[0042] D, film covering: the BOPP film after the step B treatment is covered on the film covering surface of the paper blank after the step C treatment;

[0043] E. Softening of the drying tunnel: put the paper blank after the film-coating treatment in step D into a drying tunnel with a length of 140cm, set the temperature of the drying tunnel at 63°C, and keep the atmospheric pressure in the drying tunnel at a low pressure state, so that the paper blank is covered with BOPP film high temperature softening;

[0044] F, forming: the paper base processe...

Embodiment 3

[0052] A method for covering a sterile carton blank, comprising the steps of:

[0053] A. Material collection: take BOPP specification film with a thickness of 17 μm, and perform corona treatment on the BOPP film;

[0054] B, gluing: use a gluing roller to coat a film surface of the BOPP film after the above-mentioned steps;

[0055] C. Paper base treatment: evenly apply leveling agent solution to the film-coated surface of the paper base;

[0056] D, film covering: the BOPP film after the step B treatment is covered on the film covering surface of the paper blank after the step C treatment;

[0057] E. Softening of the drying tunnel: put the paper blank after the film-coating treatment in step D into a drying tunnel with a length of 120cm, set the temperature of the drying tunnel at 61°C, and keep the atmospheric pressure in the drying tunnel at a low pressure state, so that the paper blank is covered with BOPP film high temperature softening;

[0058] F, forming: the pape...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap