Fully biodegradable composite film and preparation method thereof

A composite film, fully degradable technology, applied in the field of medical and packaging materials, can solve the problems of unfavorable promotion and practicality, poor stability, etc., and achieve the effect of good hydrolysis, good mechanical properties, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with specific examples.

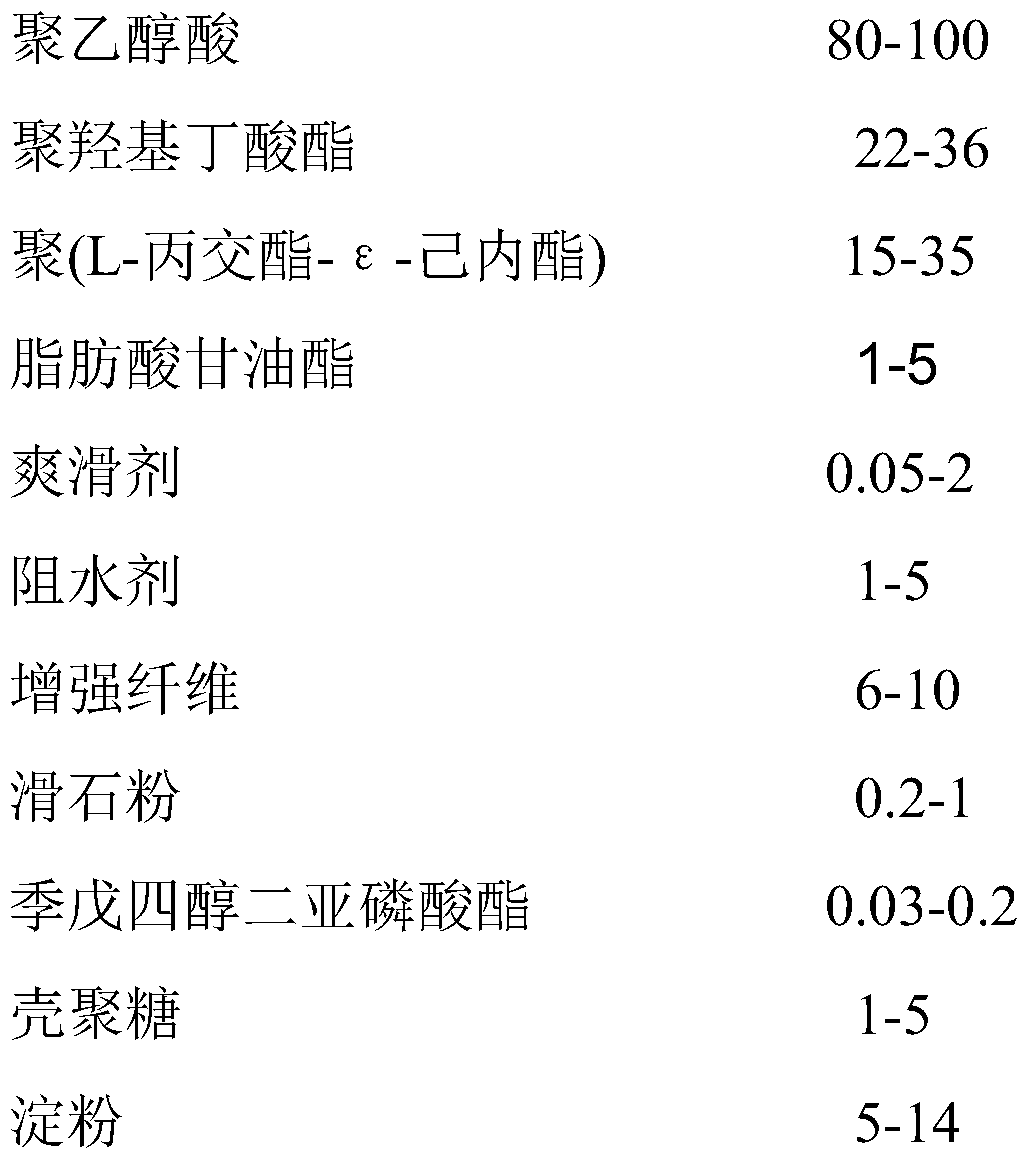

[0034] A fully degradable composite film is preferably made of the following components in parts by weight:

[0035]

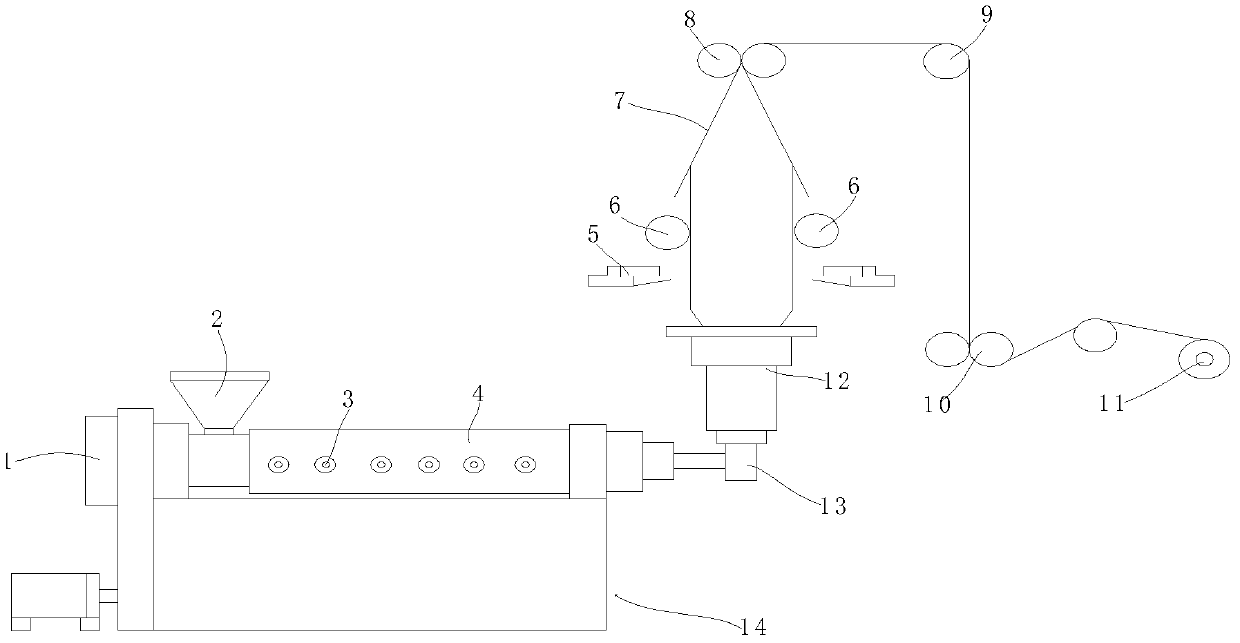

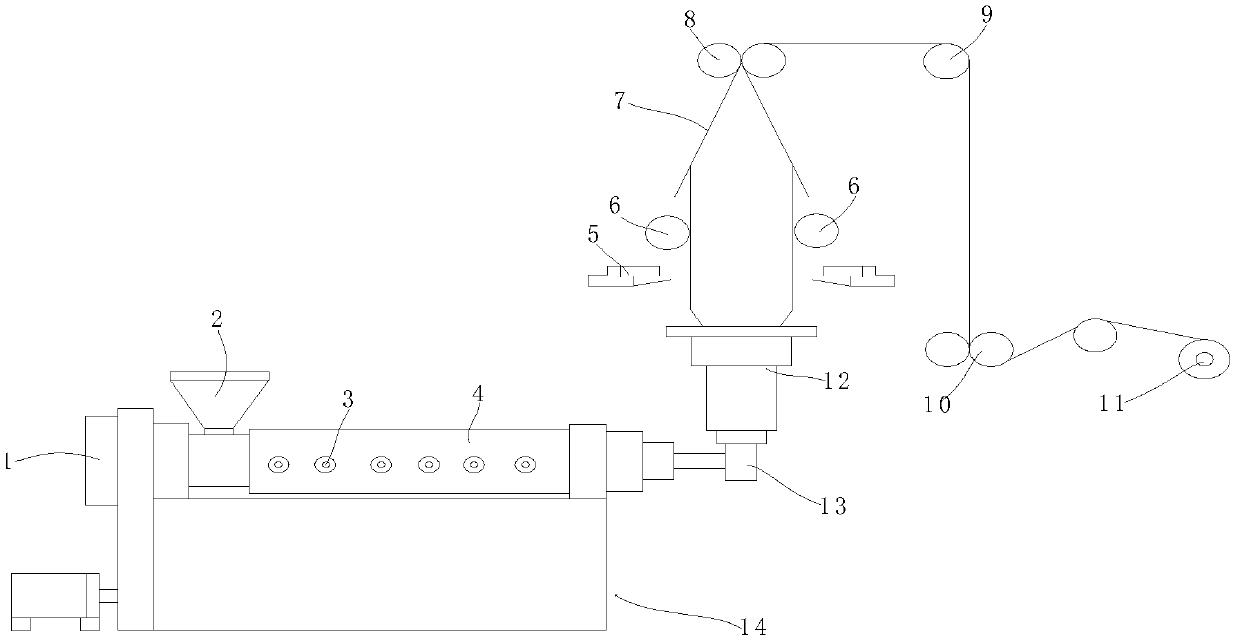

[0036] The preparation method of the above-mentioned fully degradable composite film comprises the following steps:

[0037] (1) Pulverize polyglycolic acid, polyhydroxybutyrate, poly(L-lactide-ε-caprolactone) and pentaerythritol diphosphite under a low-temperature ultrafine pulverizer to obtain an average particle size of 60-80 μm granules, and mix evenly to form a mixed main ingredient;

[0038] (2) Add slip agent, water blocking agent, reinforcing fiber, talcum powder, chitosan and starch, grind and pulverize under a low-temperature ultrafine pulverizer to obtain particles with an average particle size of 60-80 μm, and mix them uniformly to form mixed auxiliary materials;

[0039] (3) Mix the mixed main material, mixed auxiliary material and fatty ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com