High-strength structural adhesive for bonding rubber and concrete, and preparation method thereof

A high-strength structural adhesive and rubber bonding technology, applied in the field of structural adhesives, can solve the problems of weak ultraviolet and aging resistance of structural adhesives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] In one embodiment, the preparation method of described modified nanometer calcium carbonate comprises the following steps:

[0049] Ultrasonic dispersion of nano-calcium carbonate, heating, then adding coupling agent A, stirring, cooling, filtering, washing with water, drying, and grinding.

[0050] Preferably, the ultrasonic dispersion time in the preparation of the modified nano-calcium carbonate is 30-45 minutes.

[0051] More preferably, the ultrasonic dispersion time in the preparation of the modified nano-calcium carbonate is 45min.

[0052] Preferably, during the preparation of the modified nano-calcium carbonate, heating is performed at 50-75°C.

[0053] More preferably, in the preparation of described modified nanometer calcium carbonate, be heated to 75 ℃

[0054] Preferably, the preparation of the modified nano-calcium carbonate is stirred for 1-2 hours.

[0055] More preferably, stirring for 2 hours in the preparation of the modified nano-calcium carbonat...

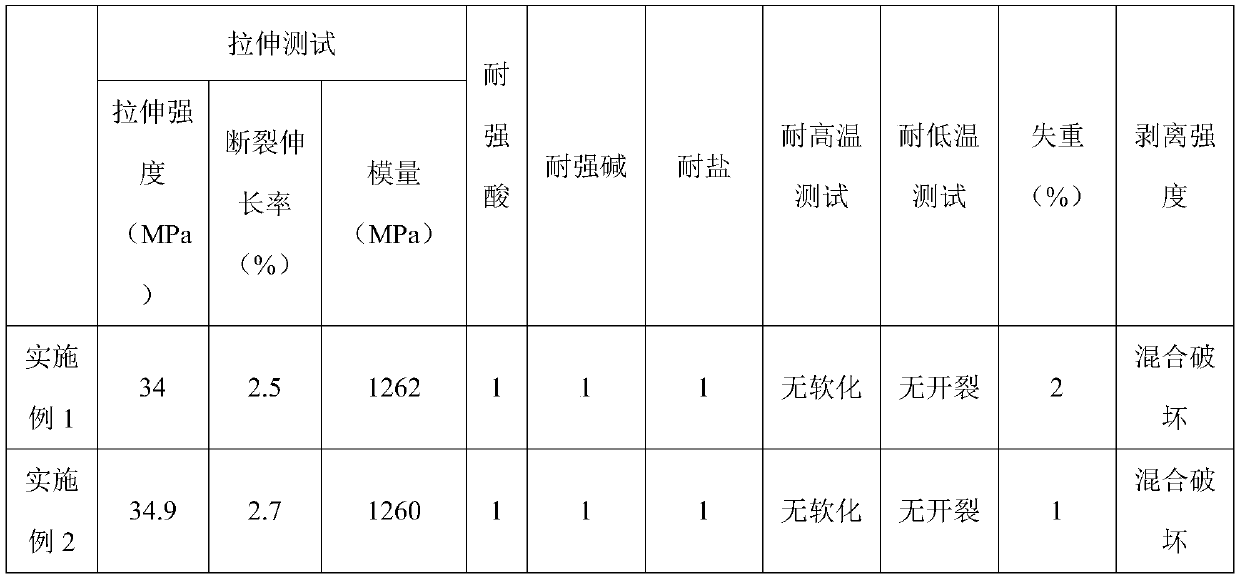

Embodiment 1

[0109] Embodiment 1 of the present invention provides a high-strength structural adhesive for bonding rubber and concrete. The high-strength structural adhesive includes component A, component B and a primer.

[0110] The preparation method of described high-strength structural adhesive comprises the following steps:

[0111] (1) Mix the components in Group A evenly for use;

[0112] (2) Mix the components in component B evenly and set aside;

[0113] (3) Mix the components in the primer evenly and set aside.

[0114] In parts by weight, the group A includes 35 parts of polyester polyol, 1 part of polyether polyol, 50 parts of nano calcium carbonate, 1 part of modified nano calcium carbonate, 0.3 part of small molecule polyol, 1 part of silane joint agent.

[0115] In parts by weight, the component B includes 90 parts of isocyanate and 0.01 part of organotin catalyst.

[0116] In parts by weight, the primer includes 2 parts of trichloroisocyanuric acid and 90 parts of smal...

Embodiment 2

[0134] Embodiment 2 of the present invention provides a high-strength structural adhesive for bonding rubber and concrete. The high-strength structural adhesive includes component A, component B and a primer.

[0135] In parts by weight, said group A includes 40 parts of polyester polyol, 5 parts of polyether polyol, 60 parts of nano calcium carbonate, 5 parts of modified nano calcium carbonate, 4 parts of small molecule polyol, 10 parts of fumed white Carbon black, 2 parts of silane coupling agent.

[0136] In parts by weight, the component B includes 99.99 parts of isocyanate and 1 part of organotin catalyst.

[0137] In parts by weight, the primer includes 5 parts of trichloroisocyanuric acid and 98 parts of small molecule organic solvents.

[0138] The polyester polyol is castor oil polyol, and the trade mark is Polycin GR-80.

[0139] The polyether polyol is polyoxypropylene triol, purchased from Shandong Binjiang Jinsheng New Material Technology Co., Ltd.

[0140] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com