Migration-resisting plasticizer for polyurethane sealant and polyurethane building sealant

A technology of migration-resistant plasticizer and sealant, applied in the field of sealant, to achieve the effect of good water removal, simple process and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

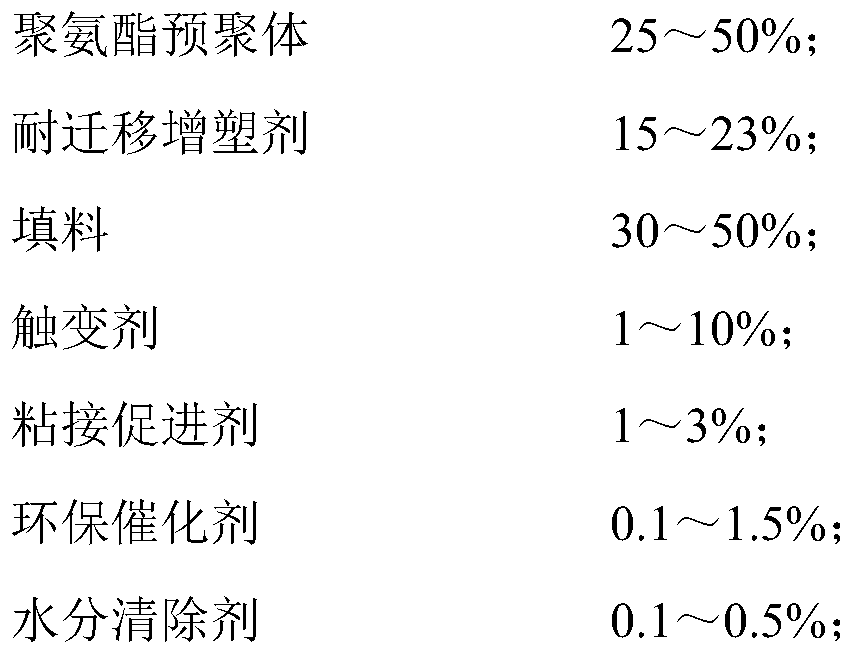

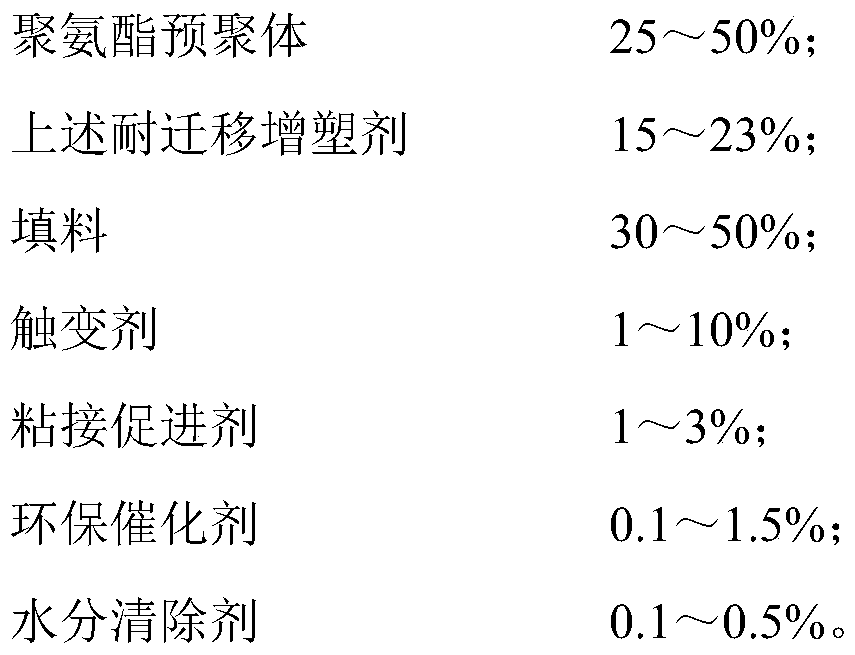

[0050] A kind of anti-migration plasticizer for polyurethane sealant, this anti-migration plasticizer is prepared by comprising the following components by mass percentage:

[0051] Polyoxypropylene diol (4000) 90.1%

[0052] Toluene diisocyanate 7.8%

[0053] Ethanol 2.1%

[0054] The above-mentioned anti-migration plasticizer is prepared by the following method:

[0055] (1) Prepare raw materials according to the above-mentioned components of mass proportioning;

[0056] (2) polyoxypropylene polyol is added in the reactor that stirrer, nitrogen inlet and thermometer are equipped with and fully mixes;

[0057] (3) Rapidly heat up to 115°C and dehydrate under vacuum for 2.5 hours until the water content is less than 200ppm, then cool down to 55°C;

[0058](4) Add the formula equivalent polyisocyanate, and determine the reaction to the theoretical end point by titrating the NCO content at 80°C.

[0059] (5) Add the capping agent equivalent to the formula, and confirm that ...

Embodiment 2

[0062] A kind of anti-migration plasticizer for polyurethane sealant, this anti-migration plasticizer is prepared by comprising the following components by mass percentage:

[0063] Polyoxypropylene diol (3000) 85.8%

[0064] Toluene diisocyanate 10%

[0065] Butanol 4.2%

[0066] The above-mentioned anti-migration plasticizer is prepared by the following method:

[0067] (1) Prepare raw materials according to the above-mentioned components of mass proportioning;

[0068] (2) polyoxypropylene polyol is added in the reactor that stirrer, nitrogen inlet and thermometer are equipped with and fully mixes;

[0069] (3) Rapidly heat up to 110°C and dehydrate under vacuum for 3 hours until the water content is less than 200ppm, then cool down to 55°C;

[0070] (4) Add the formula equivalent polyisocyanate, and determine the reaction to the theoretical end point by titrating the NCO content at 85°C.

[0071] (5) Add an equivalent amount of capping agent to the formula, confirm th...

Embodiment 3

[0074] A kind of anti-migration plasticizer for polyurethane sealant, this anti-migration plasticizer is prepared by comprising the following components by mass percentage:

[0075] Polyoxypropylene diol (2000) 73.9%

[0076] Isophorone Diisocyanate 16.5%

[0077] n-octanol 9.6%

[0078] The above-mentioned anti-migration plasticizer is prepared by the following method:

[0079] (1) Prepare raw materials according to the above-mentioned components of mass proportioning;

[0080] (2) polyoxypropylene polyol is added in the reactor that stirrer, nitrogen inlet and thermometer are equipped with and fully mixes;

[0081] (3) Rapidly heat up to 120°C and dehydrate under vacuum for 2.5 hours until the water content is less than 200ppm, then cool down to 70°C;

[0082] (4) Add the formula equivalent polyisocyanate, and determine the reaction to the theoretical end point by titrating the NCO content at 100°C.

[0083] (5) Add the capping agent equivalent to the formula, and confi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com