A production formula of high-speed chemical fiber godet roller for spinning polyester filament

A polyester filament and godet roller technology, which is applied in the direction of filament production, textiles and papermaking, etc., can solve the problems of poor stability of tow conveying, unsatisfactory false twist effect, unstable draft ratio, etc. quality, reduce maintenance difficulty, high corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

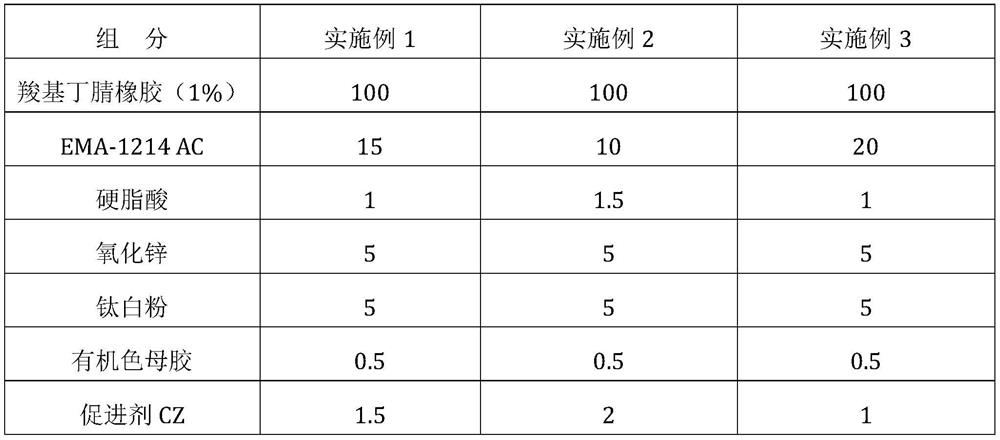

[0019] Embodiment 1~Example 3 Weigh the raw materials according to the weight ratio shown in Table 1, then adopt the closed type rubber mixing machine to carry out prefabricated nitrile rubber and EMA-1214AC elastomer heat kneading masterbatch, then through closed type mixing The rubber machine is mixed to make rubber products.

[0020] Table 1:

[0021]

[0022]

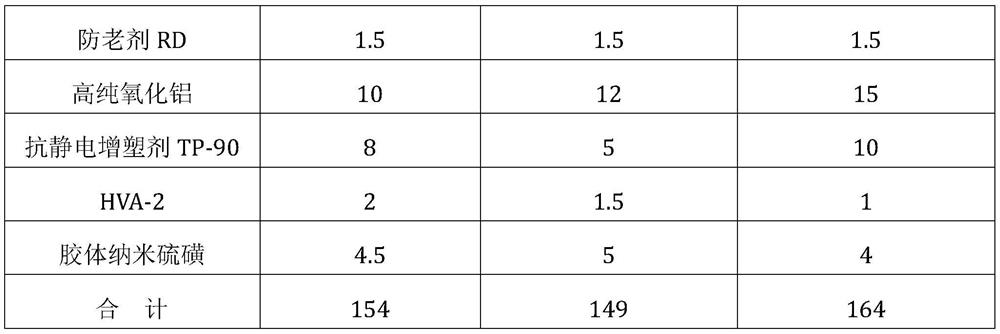

[0023] The rubber products obtained in Examples 1 to 3 are tested according to the detection standards of "GB / T528-2009", "GB / T531.1-2008", "GB / T1689-1998", and "GB / T3512-2001" Test, the results are shown in Table 2:

[0024] Table 2:

[0025]

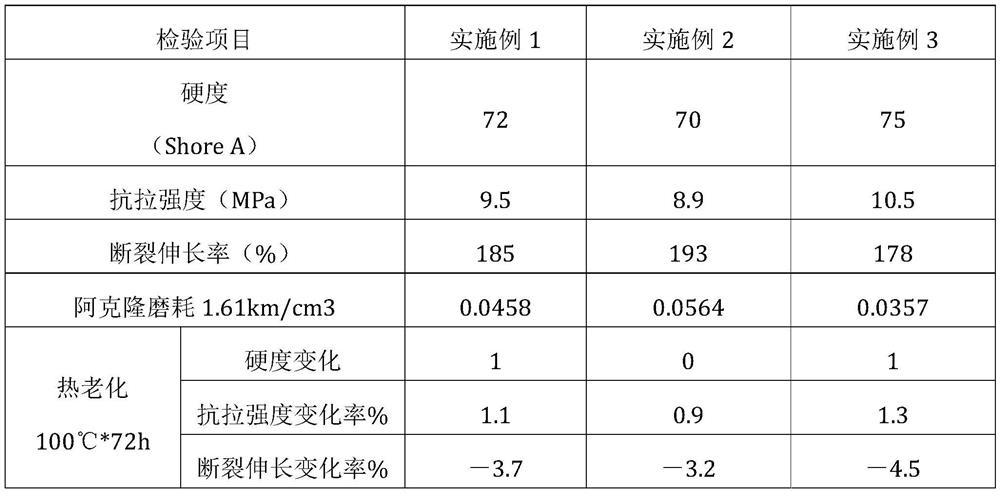

[0026] Then the rubber products obtained in the above-mentioned Examples 1 to 3 are processed into spinning cots, and the detection test is carried out according to the detection standards of the standards "GB / T7759-1996" and "GB / T1681-2009", and the detection results are shown in Table 3 Shown:

[0027] table 3:

[0028] Test items Example 1 Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com