High-temperature micro-nano indentation testing device and method with inert gas protection function

A technology with inert gas and protective functions, which is applied in the field of high-temperature micro-nano indentation test equipment, can solve problems such as lack of observation methods, observation of surface morphology, and huge influence on mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

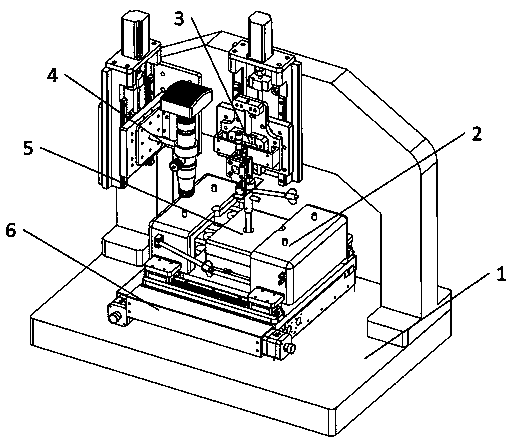

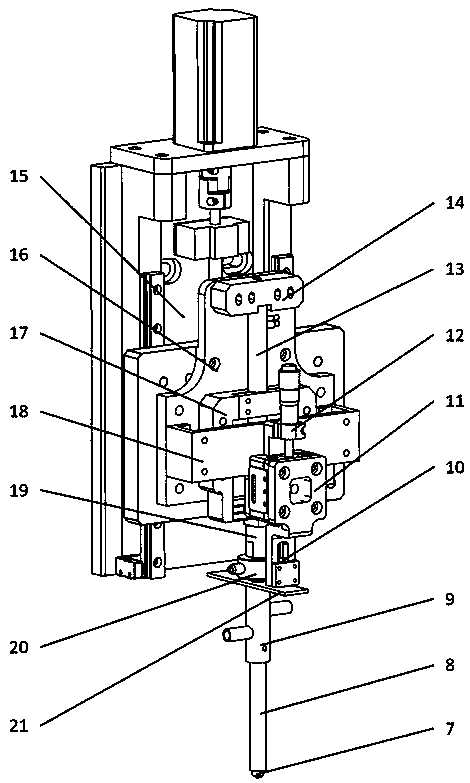

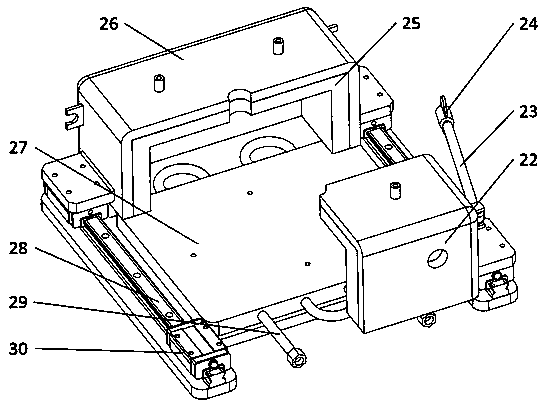

[0057] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0058] see Figure 1 to Figure 10 As shown, the high-temperature micro-nano indentation test device and method with inert gas protection function of the present invention can carry out the test of the micro-nano indentation response and mechanical properties of materials in a high temperature environment from room temperature to 800 °C under the protection of inert gas. The coaxial microscope with filter lens can observe the surface topography and deformation damage in the indentation area of the material test sample under the action of high temperature in situ. The invention has the advantages of compact structure, high degree of modularization, high test accuracy, controllable environment and easy operation and use, and provides an effective technical means for studying the micro-mechanical behavior, deformati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com