Cloud intelligent system

A technology of intelligent system and cloud system, which is applied in the field of cloud intelligent system, can solve the problems of high labor cost, time-consuming and laborious, occupation, etc., and achieve the effects of fast cost recovery, security guarantee, and large finished product output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 101

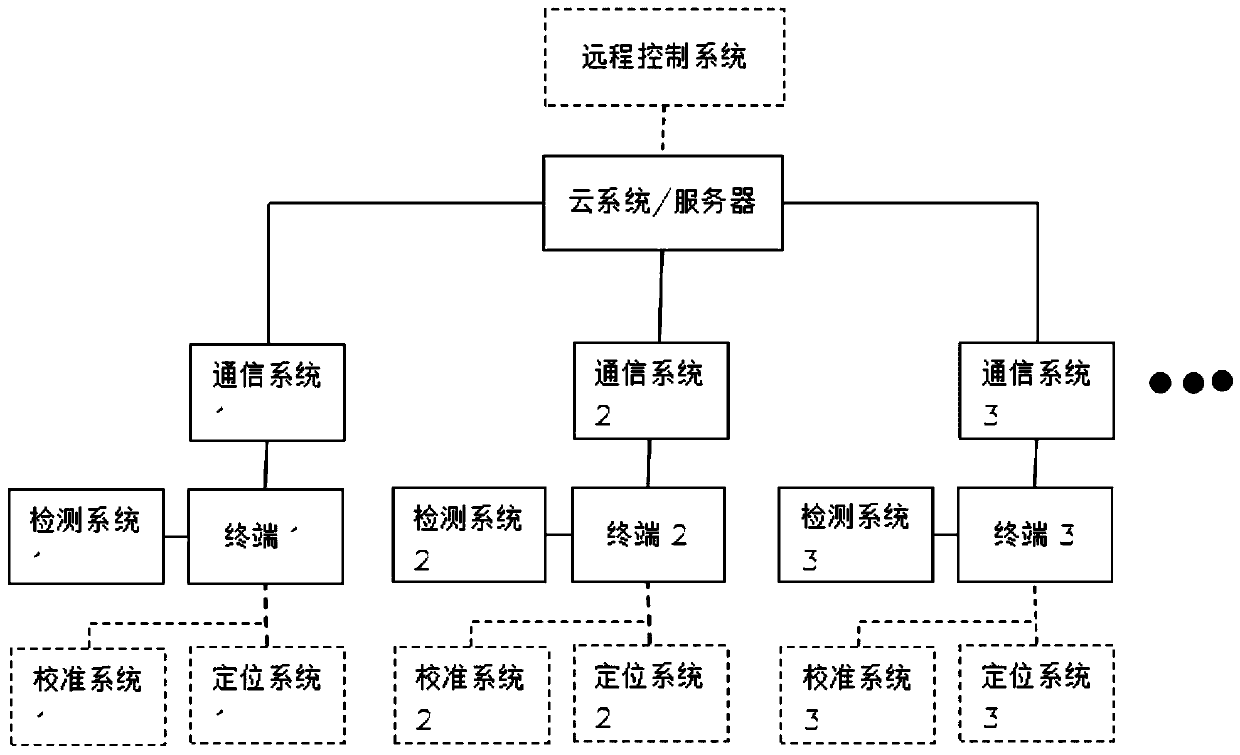

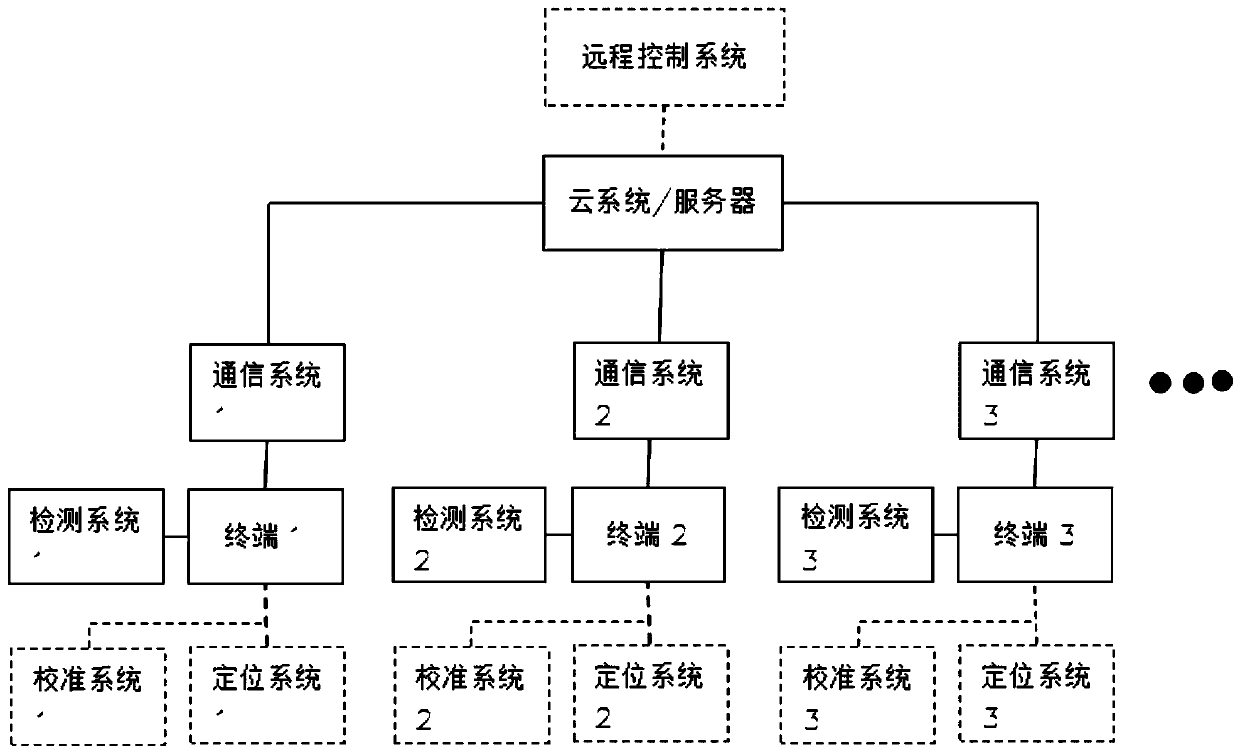

[0054] In this embodiment, the cloud intelligent system includes a terminal, a monitoring system, a communication system, and a cloud system / server; at this time, the servo system used as a driver in the terminal feeds back relevant parameters synchronously to the monitoring system for supplementation or calibration. When there is no special external sensor for detection such as output power, it will be directly output through the servo system; calibration means that when a special external sensor is set for detection such as output power, the relevant detection results of the servo system output and the sensor will be checked. to improve accuracy, where

[0055] Cloud system / server for receiving data, performing comparison, and feeding back comparison information;

[0056] And a terminal, which may be a machine tool (including but not limited to lathes, milling machines, grinding machines, boring machines, planers, drilling machines, punching machines, forging machines, crank...

Embodiment 102

[0063] In this embodiment, the cloud intelligent system includes a terminal, a monitoring system, a communication system and a cloud system / server, wherein

[0064] Cloud system / server for receiving data, performing comparison, and feeding back comparison information;

[0065] And a terminal, which may be a machine tool (including but not limited to lathes, milling machines, grinding machines, boring machines, planers, drilling machines, punching machines, forging machines, crankshaft machine tools, etc.), used to perform production and processing operations on the workpiece to be processed according to instructions;

[0066] and a monitoring system, used to extract the data of the workpiece to be processed before and / or during and / or after the execution of the production and processing operation and / or the operation information of the terminal itself to obtain monitoring data;

[0067] and communication systems for performing data transfers between terminals and / or surveillan...

Embodiment 103

[0072] In this embodiment, the cloud intelligent system includes a terminal, a monitoring system, a communication system and a cloud system / server, wherein

[0073] Cloud system / server for receiving data, performing comparison, and feeding back comparison information;

[0074] And a terminal, which may be a machine tool (including but not limited to lathes, milling machines, grinding machines, boring machines, planers, drilling machines, punching machines, forging machines, crankshaft machine tools, etc.), used to perform production and processing operations on the workpiece to be processed according to instructions;

[0075] And monitoring system which has an online laser sensor (other types of sensors can also be used), which has a distance measurement function, and is used to extract the workpiece to be processed before and / or during the production processing operation and / or during the production processing operation Obtain monitoring data from the data after job execution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com