Ampelopsis grossedentata tea and manufacturing process thereof

A production process, the technology of vine tea, applied in the field of vine tea and its production process, can solve problems that have not been seen yet, achieve the effects of preventing cancer cell proliferation and spread, improving human immunity, and anti-cancer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

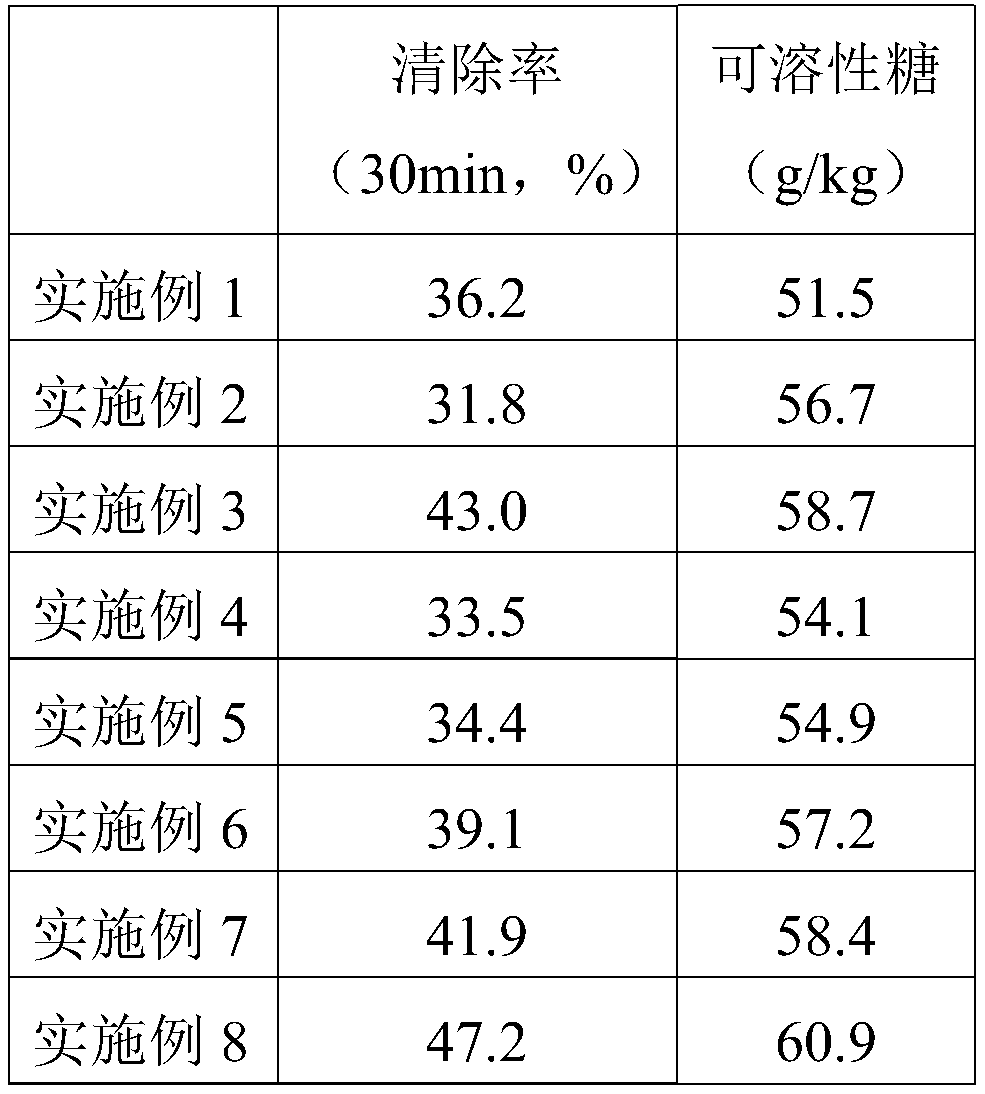

Examples

Embodiment 1

[0044] The manufacture craft of rattan tea comprises the following steps:

[0045] (1) Harvest the fresh leaves of the vines of the vine, wash them with water, and spread the fresh leaves of the vines of the vines after cleaning on a bamboo mat to cool them. Dry for 5 hours at a relative humidity of 60%;

[0046] (2) Spray selenium-enriched nutrient solution: evenly spray selenium-enriched nutrient solution to the dried fresh leaves of the vines of the vine, the amount of the selenium-enriched nutrient solution is the weight of the fresh leaves of the vines of the vine after drying 3%;

[0047] (3) Finishing: Use a finishing machine (model: SQ-60, the diameter of the drum is 600mm, the speed is 30r / min, the power is 1.1kW, the manufacturer is Changsha Xiufeng Agricultural Technology Co., Ltd.) for finishing, and the finishing temperature is 110°C , when the water content of the tea leaves is 45wt%, finish finishing;

[0048] (4) Kneading: After finishing, cool to room tempe...

Embodiment 2

[0053] The manufacture craft of rattan tea comprises the following steps:

[0054] (1) Harvest the fresh leaves of the vines of the vine, wash them with water, and spread the fresh leaves of the vines of the vines after cleaning on a bamboo mat to cool them. Dry for 5 hours at a relative humidity of 60%;

[0055] (2) Spray selenium-enriched nutrient solution: evenly spray selenium-enriched nutrient solution to the dried fresh leaves of the vines of the vine, the amount of the selenium-enriched nutrient solution is the weight of the fresh leaves of the vines of the vine after drying 3%;

[0056] (3) Finishing: Use a finishing machine (model: SQ-60, the diameter of the drum is 600mm, the speed is 30r / min, the power is 1.1kW, the manufacturer is Changsha Xiufeng Agricultural Technology Co., Ltd.) for finishing, and the finishing temperature is 110°C , when the water content of the tea leaves is 45wt%, finish finishing;

[0057] (4) Kneading: After finishing, cool to room tempe...

Embodiment 3

[0062] The manufacture craft of rattan tea comprises the following steps:

[0063] (1) Harvest the fresh leaves of the vines of the vine, wash them with water, and spread the fresh leaves of the vines of the vines after cleaning on a bamboo mat to cool them. Dry for 5 hours at a relative humidity of 60%;

[0064] (2) Spray selenium-enriched nutrient solution: evenly spray selenium-enriched nutrient solution to the dried fresh leaves of the vines of the vine, the amount of the selenium-enriched nutrient solution is the weight of the fresh leaves of the vines of the vine after drying 3%;

[0065] (3) Finishing: Use a finishing machine (model: SQ-60, the diameter of the drum is 600mm, the speed is 30r / min, the power is 1.1kW, the manufacturer is Changsha Xiufeng Agricultural Technology Co., Ltd.) for finishing, and the finishing temperature is 110°C , when the water content of the tea leaves is 45wt%, finish finishing;

[0066] (4) Kneading: After finishing, cool to room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com