Mobile particle bed dust filter device with automatic particle size stratification and filter material stratification replacement

A dust filter device and a technology of moving particle beds, which are applied in the direction of dispersed particle filtration, dispersed particle separation, and separation methods, can solve the problems of fixed particle layer thickness, large replacement heat loss, and low dust holding rate of the filter layer, and achieve reduction Discharging heat loss, reducing the effect of discharging heat loss and reducing filter material replacement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0034] The invention provides a moving particle bed dust filter device with automatic particle size layering and layered replacement of filter material to solve the problems of low filter layer dust holding rate, large bed resistance, and filter material problems in the existing moving bed particle layer filtration technology. Problems such as high replacement rate and large waste heat loss.

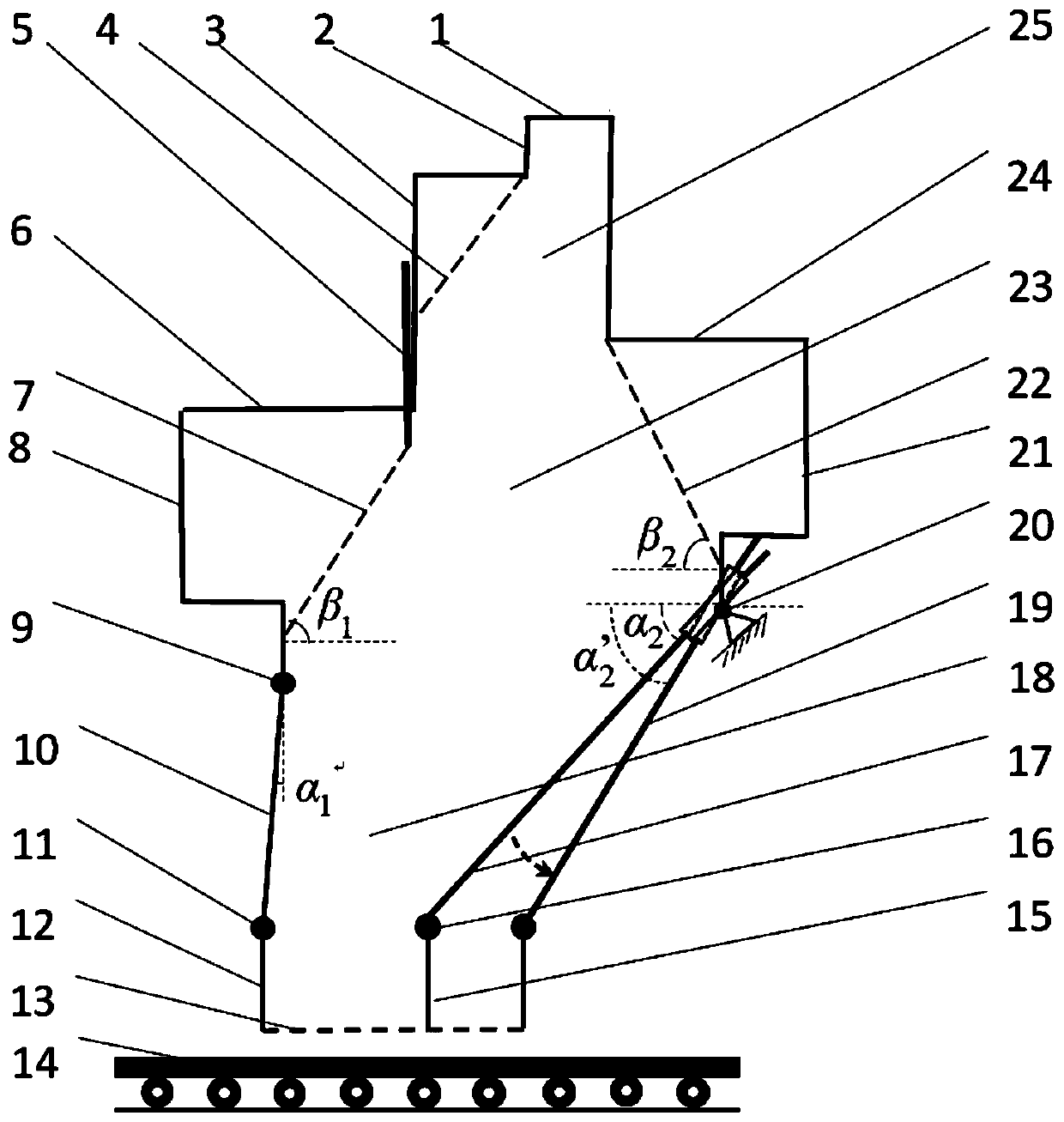

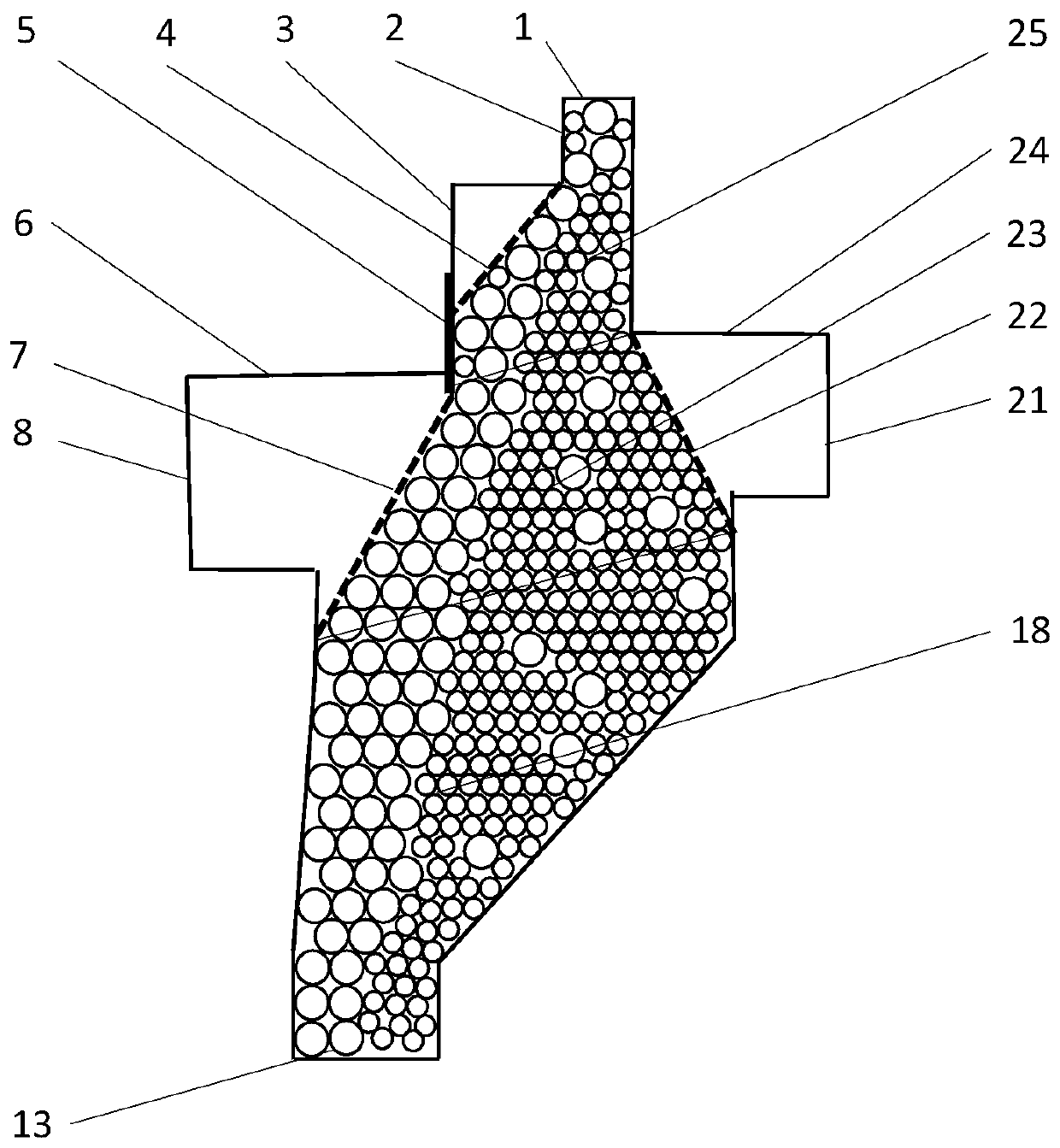

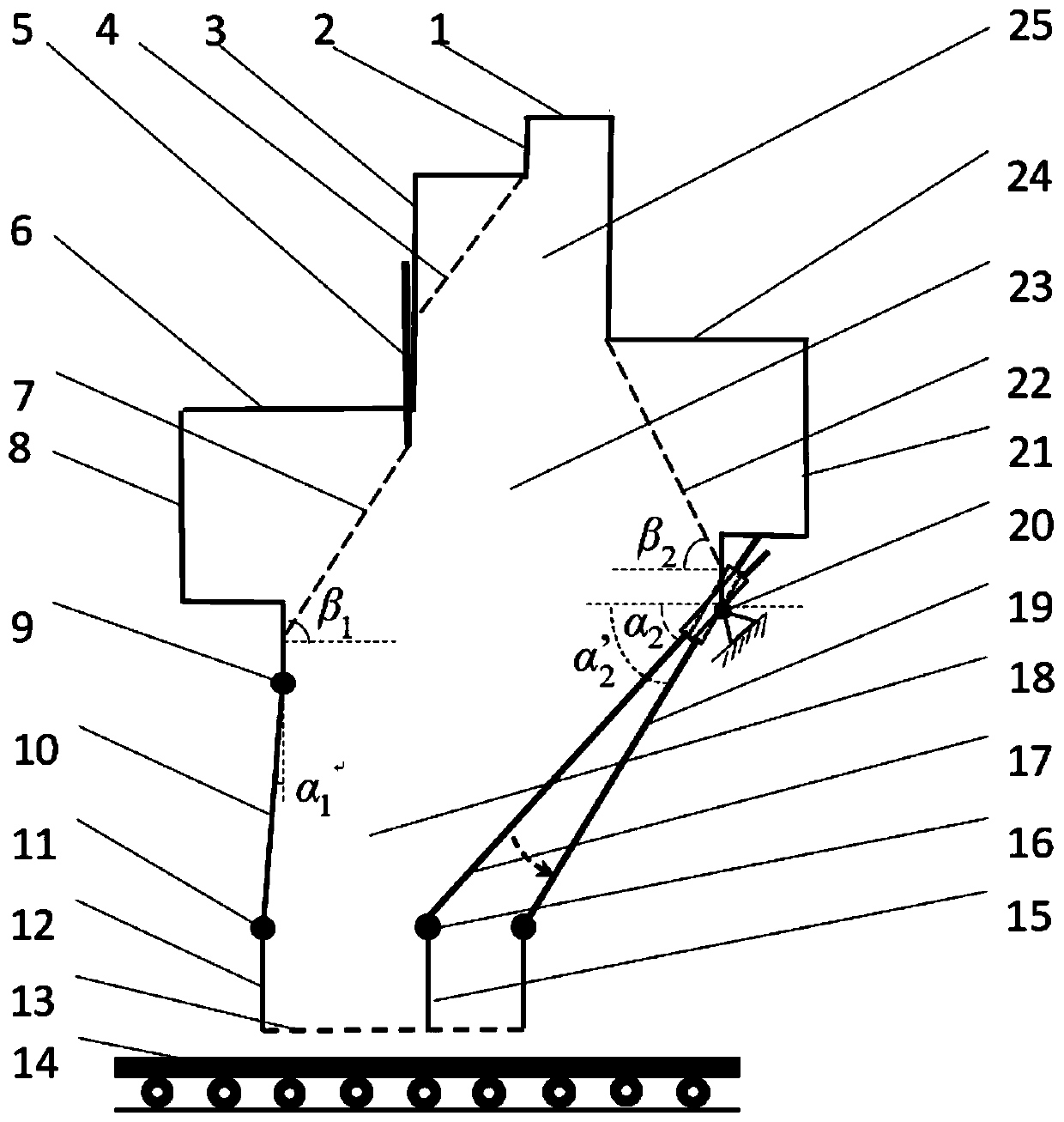

[0035] Such as figure 1 As shown, the device is a particle size distribution pre-separation zone 25, a filter zone 23, and a feeding zone 18 from top to bottom. The pre-separator 3 is distributed, the filter area 23 includes the flue gas inlet channel 6, the flue gas inlet 8, the flue gas outlet 21 and the flue gas outlet channel 24, the blanking area 18 includes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com