Catalyst and preparation method and application thereof

A catalyst and porous carbon technology, applied in the field of selective reduction catalysts of unsaturated hydrocarbons and their preparation, can solve the problems of less research and achieve the effects of high catalytic activity, good catalytic activity, and reduced industrial application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be explained in more detail below in conjunction with examples and characterization data.

[0021] (1) Preparation of catalyst

[0022] 1. Preparation of carrier

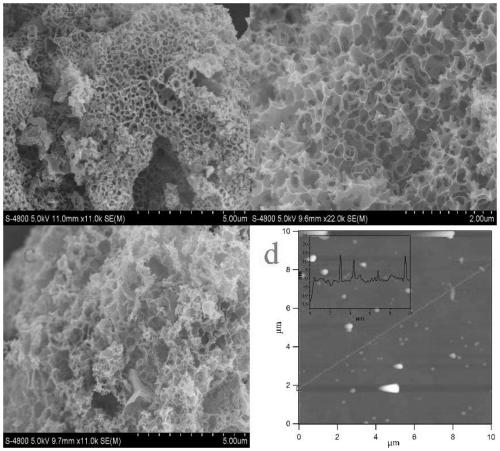

[0023] The aqueous solution of sodium glutamate and sodium salts such as sodium chloride, sodium nitrate and sodium carbonate is thoroughly mixed, evaporated to dryness and calcined to obtain CN; the nitrogen content is 1.92-4.13 wt%.

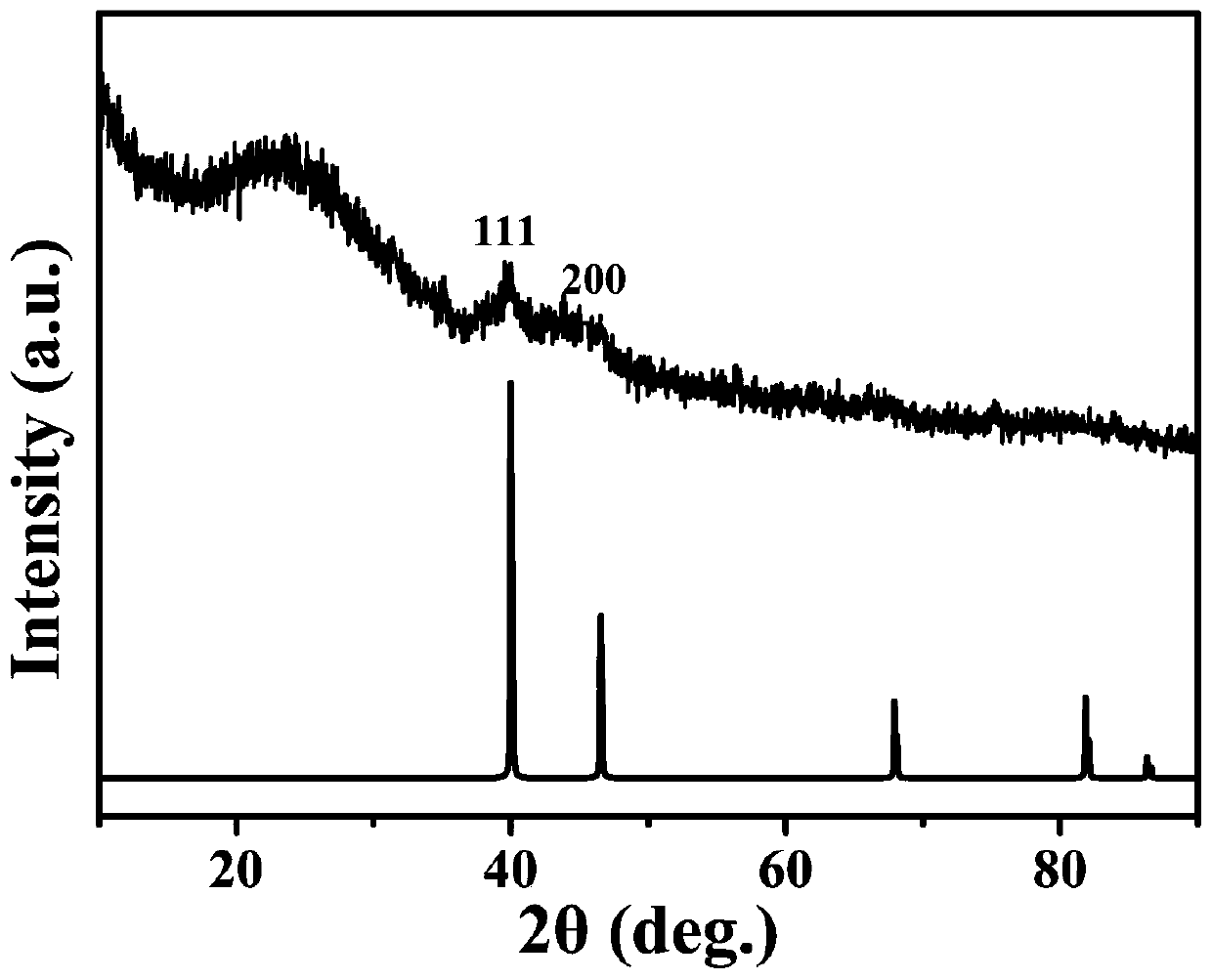

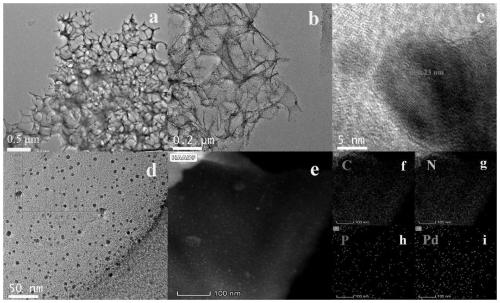

[0024] 2. Preparation of Phosphorus-free Catalyst

[0025] Take the previously prepared CN and place them in a round-bottomed flask, add absolute ethanol, add palladium salts such as palladium acetate and palladium chloride solution under stirring, evaporate to dryness to obtain a catalyst precursor, and finally calcinate the precursor under the protection of hydrogen to obtain a catalyst . The prepared catalysts were respectively CN-Pd.

[0026] 3. Preparation of phosphorus-doped catalyst: take carbon material CN and a round bottom flask, add ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com