Isostatic pressing heat preservation furnace and isostatic pressing heat preservation method for horizontal continuous cast nodular cast iron sectional material

A ductile iron and horizontal continuous casting technology, applied in the field of static pressure holding furnace, can solve problems such as equipment failure and complicated operation, and achieve the effects of improving production efficiency, stable liquid level, and improving quality and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

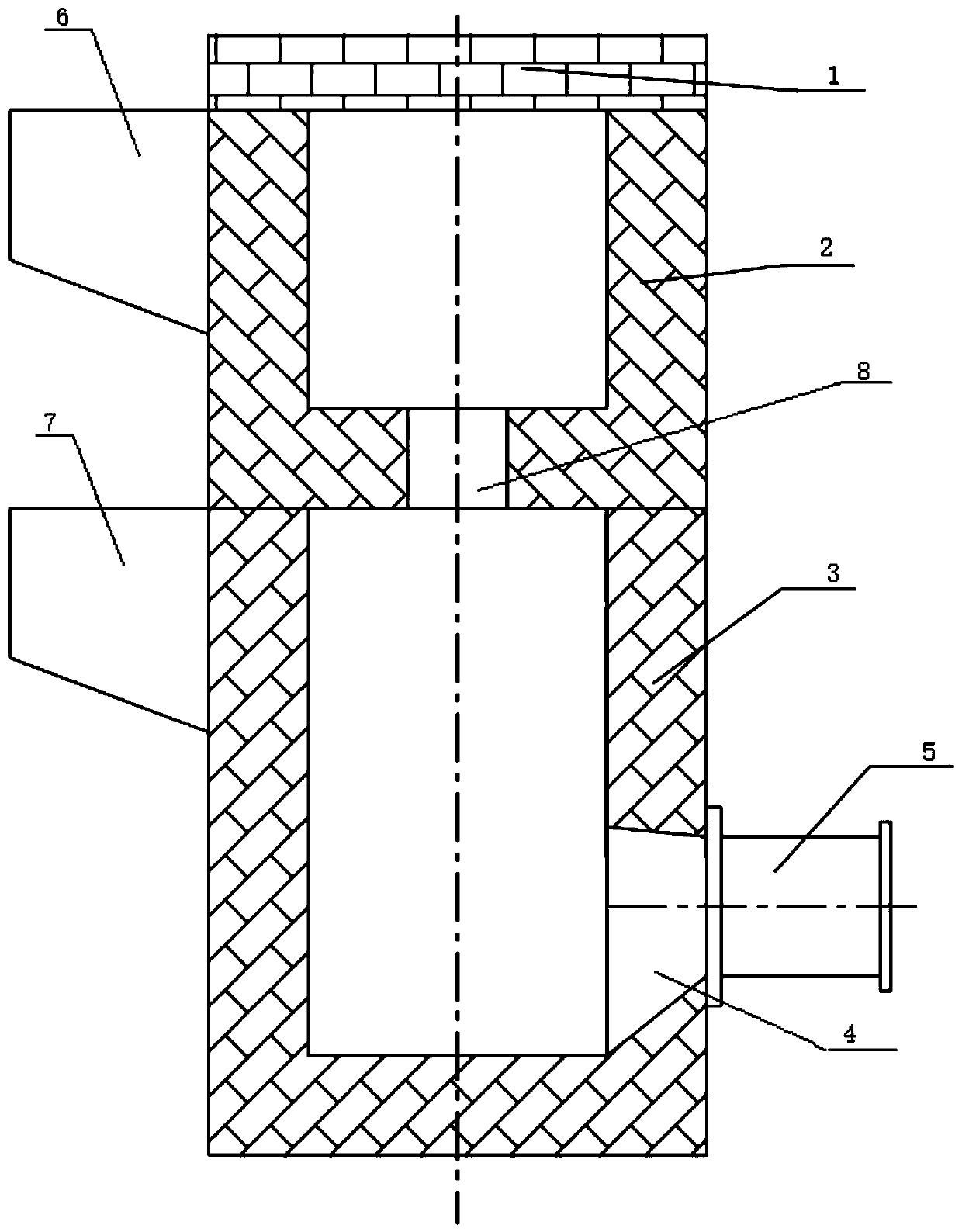

[0036] refer to figure 1 As shown, the isostatic holding furnace for horizontal continuous casting of ductile iron profiles includes a furnace body, the furnace body is composed of an upper furnace body 2 and a lower furnace body 3; the upper furnace body 2 is hinged with a furnace cover 1 , The side wall of the upper furnace body 2 is provided with an upper sprue 6, and the volume of the upper furnace body 2 is 1.2 times the amount of molten iron added each time.

[0037]A lower sprue 7 is arranged on the side wall of the lower furnace body 3 on the same side as the upper sprue 6 , and the gate area of the lower sprue 7 is smaller than that of the upper sprue 6 . A crystallizer interface 4 and a crystallizer 5 installed on the crystallizer interface 4 are provided at the middle and lower part of the side wall of the lower furnace body 3 opposite to the lower sprue 7 .

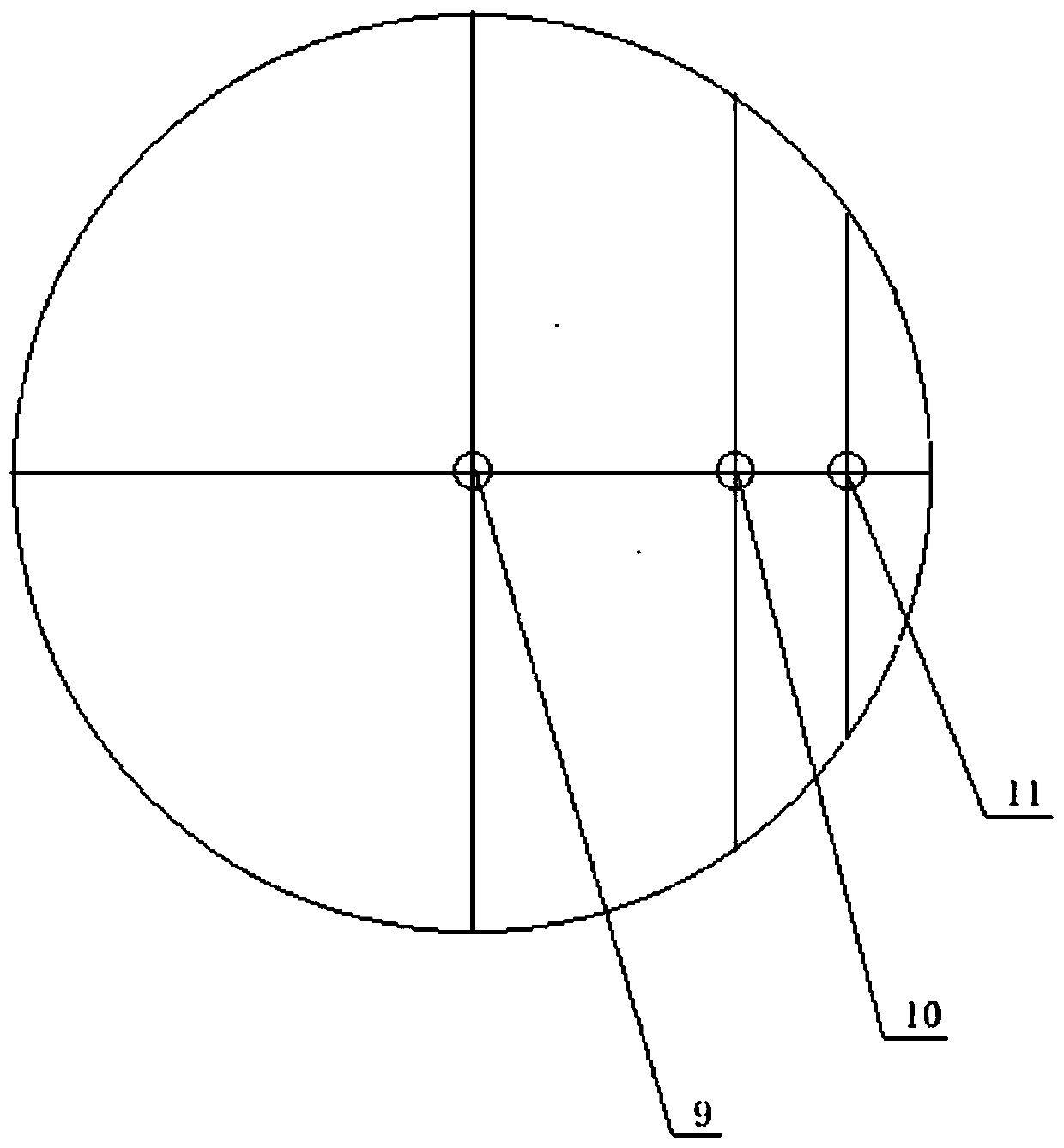

[0038] The upper furnace body 2 and the lower furnace body 3 communicate through a bottom hole 8, one en...

Embodiment 2

[0042] The preparation method for producing large-section nodular cast iron using a holding furnace is realized through the following steps:

[0043] (1) Ingredients, analyze the chemical composition of cast iron Q10, scrap steel, scrap bar / iron filings, 95% recarburizer, ferromanganese, and ferrosilicon, and then weigh the above raw materials according to the following mass percentage: C: 3.6-3.7% , Si: 1.1-1.3%, Mn: 0.25-0.35%, S<0.05%, P<0.07%, the rest is Fe;

[0044] (2) Smelting. Put the weighed cast pig iron, scrap steel, scrap bar / iron filings, 95% recarburizer, ferromanganese, and ferrosilicon into an intermediate frequency induction furnace for melting. After the raw material melting temperature reaches 1520-1550°C, the molten iron The frequency induction furnace is transferred to another holding furnace, mixed evenly with the existing molten iron, cooled to 1430-1450°C and released;

[0045] (3) Hot metal spheroidization treatment, slag removal, nodulizer and inocu...

Embodiment 3-8

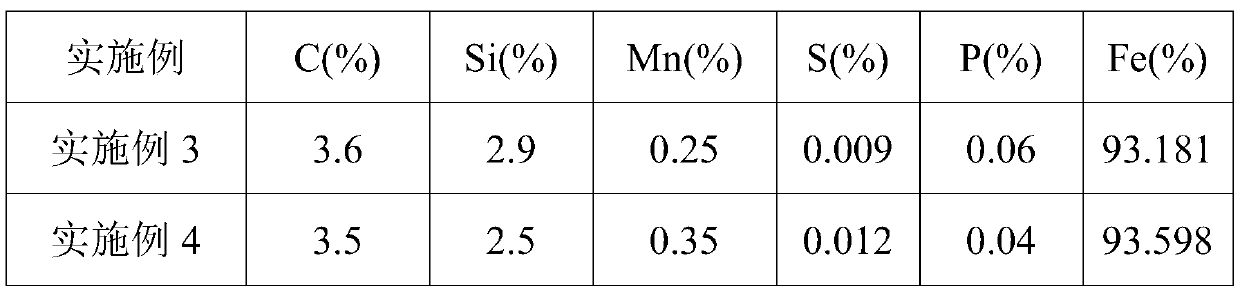

[0054] According to the production technique in the embodiment 2, the holding furnace is used to prepare large-section ductile iron profiles, and each element composition is shown in the following table:

[0055] Table 1

[0056]

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com