The invention relates to acrylate polymer and preparation method and application thereof

A technology of acrylate and polymer, applied in the direction of coating, pigment slurry, etc., can solve the problems of insufficient dryness of paint, influence of paint film physical properties, etc., and achieve the effect of good outdoor stability, excellent acid resistance, and inhibition of air oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

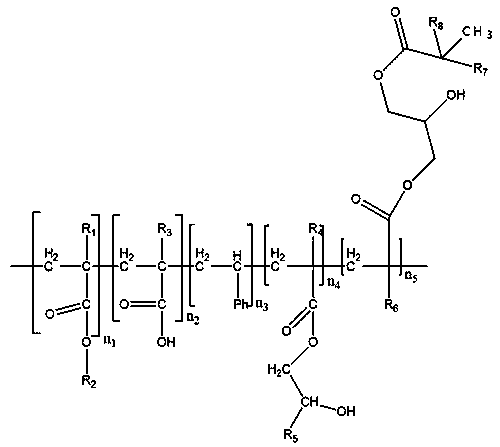

Method used

Image

Examples

Embodiment 1

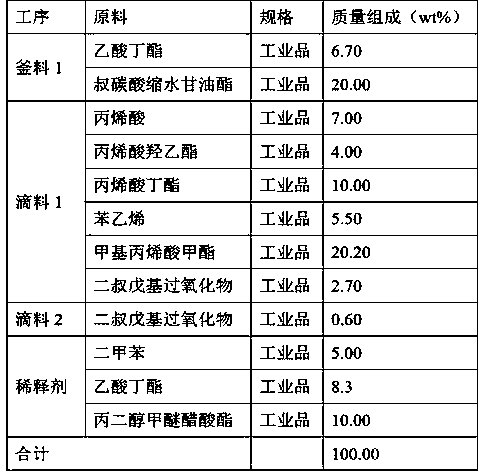

[0048] The formula of a kind of acrylate polymer is as shown in table 1:

[0049] Table 1

[0050]

[0051] A kind of preparation method of acrylate polymer comprises the following steps:

[0052] In a four-neck flask equipped with a stirrer, condenser, thermometer, and dropping funnel, add the still material 1, and then under nitrogen protection, heat up to 155 ° C and add the pre-mixed dropping material 1 dropwise with the dropping funnel. After five hours of dropwise addition, dropwise addition of drop material 2 for 0.5 hour, keep warm for 1 hour, add diluent to adjust the solid content to 67-69%, and obtain an acrylate polymer. The molecular weight and distribution are: Mn= 3955, Mw= 14306, M W / Mn=3.6, hydroxyl value (theoretical value)=105mgKOH / g. The solid content is 68.61%, the viscosity is Z1, and the acid value is 6.7.

Embodiment 2

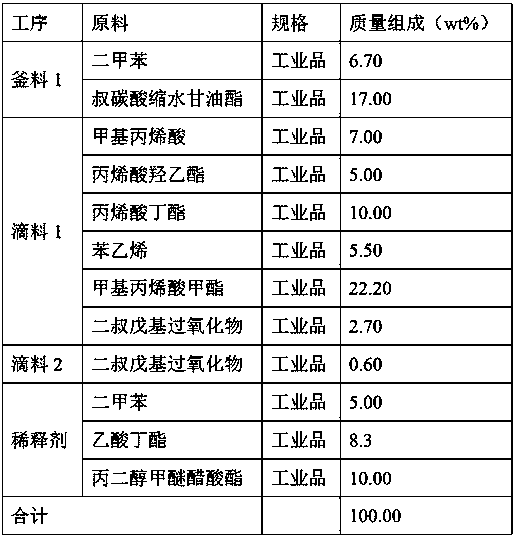

[0054] The formula of a kind of acrylate polymer is as shown in table 2:

[0055] Table 2

[0056]

[0057] A kind of preparation method of acrylate polymer comprises the following steps:

[0058] In a four-neck flask equipped with a stirrer, condenser, thermometer, and dropping funnel, add the still material 1, and then under nitrogen protection, heat up to 155 ° C and add the pre-mixed dropping material 1 dropwise with the dropping funnel. After five hours of dropwise addition, dropwise addition of drop material 2 for 0.5 hour, keep warm for 1 hour, add diluent to adjust the solid content to 67-69%, and obtain an acrylate polymer. The molecular weight and distribution are: Mn= 3520, Mw= 13000, M W / Mn=3.7, hydroxyl value (theoretical value)=99mgKOH / g. The solid content is 67.84%, the viscosity is Z2~Z3, and the acid value is 8.3.

Embodiment 3

[0060] The formula of a kind of acrylate polymer is as shown in table 3:

[0061] table 3

[0062]

[0063] A kind of preparation method of acrylate polymer comprises the following steps:

[0064] In a four-neck flask equipped with a stirrer, condenser, thermometer, and dropping funnel, add the still material 1, and then under nitrogen protection, heat up to 155 ° C and add the pre-mixed dropping material 1 dropwise with the dropping funnel. After five hours of dropwise addition, dropwise addition of drop material 2 for 0.5 hour, keep warm for 1 hour, add diluent to adjust the solid content to 67-69%, and obtain an acrylate polymer. The molecular weight and distribution are: Mn= 3056, Mw= 10716, M W / Mn=3.5, hydroxyl value (theoretical value)=96mgKOH / g. The solid content is 67.75%, the viscosity is Z2~Z3, and the acid value is 6.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com