A kind of papermaking strengthening agent and its preparation method and application

A technology of strengthening agent and dry strength agent for papermaking, applied in the directions of strengthening agent addition, papermaking, textile and papermaking, etc. Adjust the space, increase the strength, improve the stability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

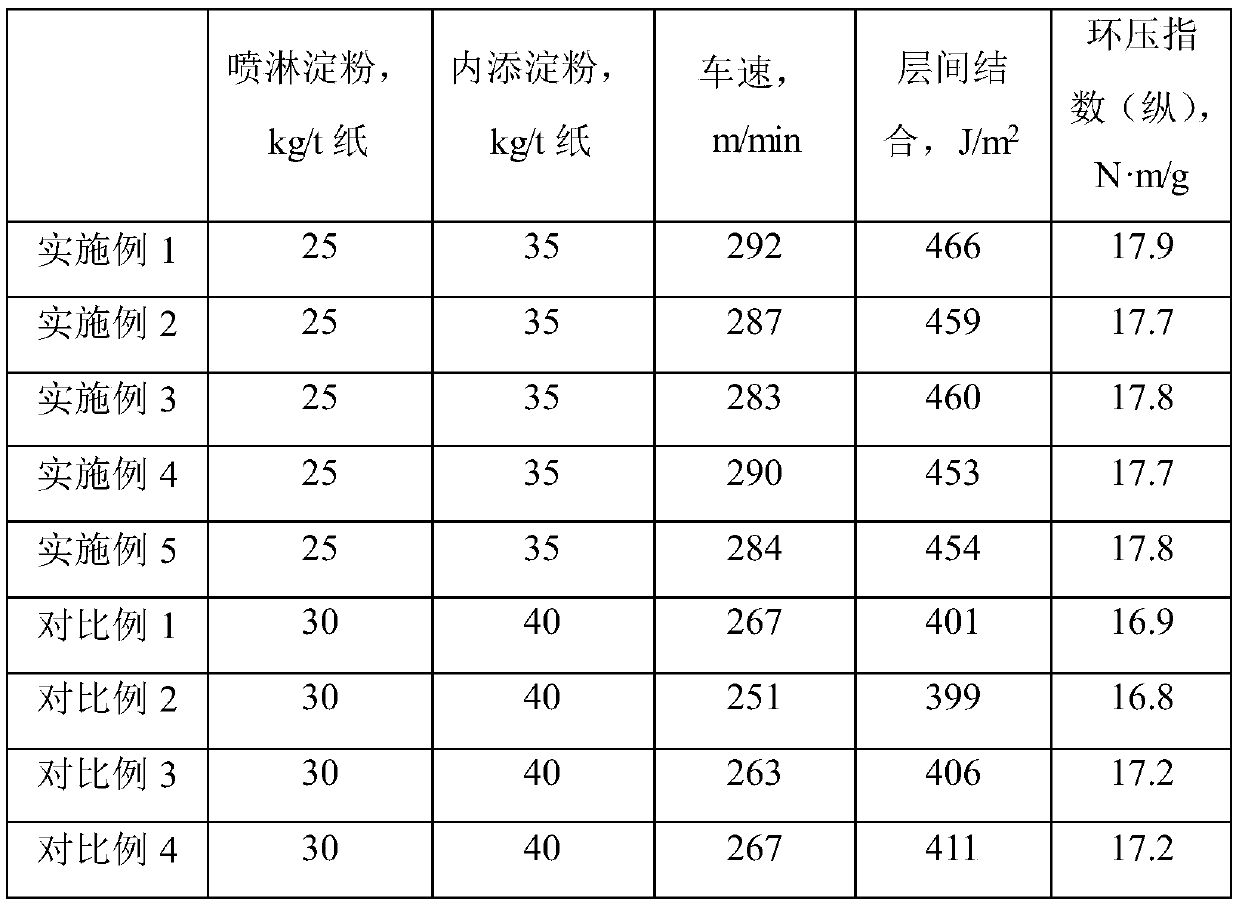

Examples

Embodiment 1

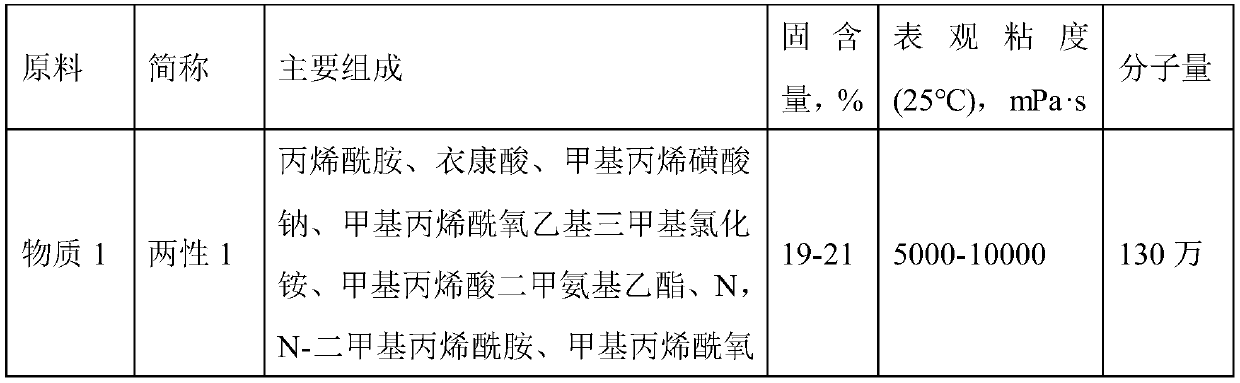

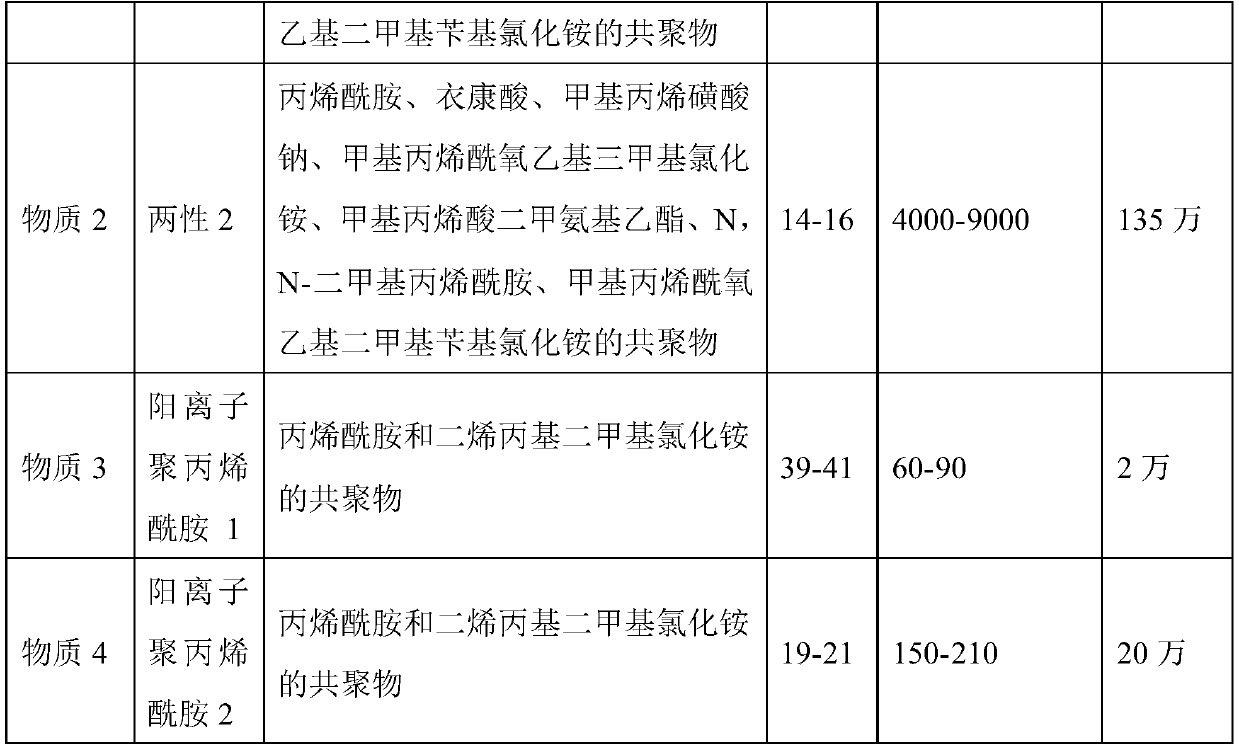

[0050] Embodiment 1 A kind of papermaking strengthening agent and its preparation

[0051] Components: 0.7 parts of cationic polyacrylamide dry strength agent 1 (substance 3), 0.5 parts of glyoxal, 1.5 parts of hydroxypropyl methylcellulose, 1.8 parts of polyaluminum chloride, 0.15 parts of 20% sodium hydroxide solution , 12 parts of 20g / ml sodium chloride solution, 45 parts of water.

[0052] Preparation:

[0053] (1) Under the condition of 25°C, the cationic polyacrylamide dry strength agent and glyoxal are metered and dosed respectively through the dosing pump, and then mixed with the sodium chloride solution pumped by the high-pressure water pump respectively, and 0.7 parts of the cationic Polyacrylamide dry strength agent is mixed with 7 parts of sodium chloride solution to obtain solution 1, the viscosity is 8000mPa·S, 0.5 parts of glyoxal and the remaining 5 parts of sodium chloride solution are mixed to obtain solution 2;

[0054] (2) Under the condition of 25°C, the...

Embodiment 2

[0061] Embodiment 2 A kind of papermaking strengthening agent and its preparation

[0062] Components: 0.5 parts of cationic polyacrylamide dry strength agent (substance 4), 0.3 parts of succinic dialdehyde, 1.3 parts of hydroxypropyl methylcellulose, 1.5 parts of polyaluminum chloride, 0.1 part of 30% sodium carbonate solution, 10 Part 18g / ml sodium chloride solution, 30 parts water.

[0063] Preparation:

[0064] (1) Under the condition of 20°C, the cationic polyacrylamide dry strength agent and succinic dialdehyde are metered and dosed respectively through the dosing pump, and then mixed with the sodium chloride solution pumped by the high-pressure water pump respectively, and 0.5 parts of the cationic Polyacrylamide dry strength agent is mixed with 2.5 parts of sodium chloride solution to obtain solution 1, the viscosity is 10000mPa·S, 0.3 parts of succinaldehyde and the remaining 7.5 parts of sodium chloride solution are mixed to obtain solution 2;

[0065] (2) Under th...

Embodiment 3

[0068] Embodiment 3 A kind of papermaking strengthening agent and its preparation

[0069] Components: 1 part of amphoteric polyacrylamide dry strength agent (substance 1), 0.8 parts of glutaraldehyde, 1.7 parts of hydroxypropyl methylcellulose, 2 parts of polyaluminum chloride, 0.2 parts of 10% ammonia water, 15 parts of saturated Sodium chloride solution, 60 parts of water.

[0070] Preparation:

[0071] (1) Under the condition of 25°C, the amphoteric polyacrylamide dry strength agent and glutaraldehyde are metered and dosed respectively through the dosing pump, and then mixed with the sodium chloride solution pumped by the high-pressure water pump, and one part of the amphoteric Polyacrylamide dry strength agent is mixed with 7.5 parts of sodium chloride solution to obtain solution 1, the viscosity is 5000mPa·S, 0.8 parts of glutaraldehyde and the remaining 7.5 parts of sodium chloride solution are mixed to obtain solution 2;

[0072] (2) Under the condition of 25°C, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com