Method for preparing micron-sized single-particle multi-TEM slice sample in situ

An in-situ preparation, single-particle technology, applied in the fields of planetary science and planetary exploration, can solve the problems of large-sized micron-scale sample preparation, waste of sample resources, and difficulty in applying micron-scale powder samples, etc. The effect of overcoming area damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this example, an optical microscope, a nanomanipulator and a double-beam electron microscope are combined to prepare micron-sized single-particle multiple TEM flake samples in situ, and the steps are as follows:

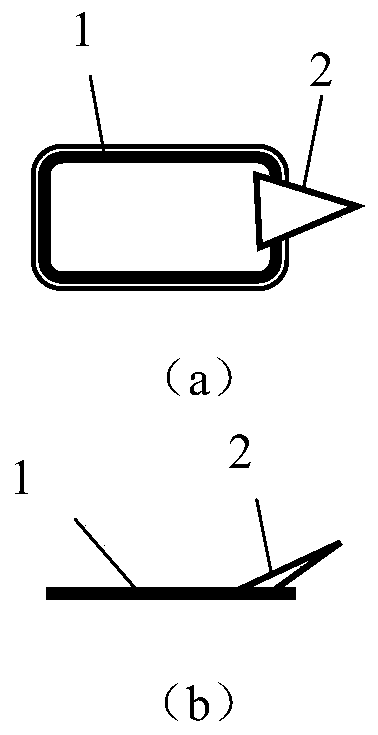

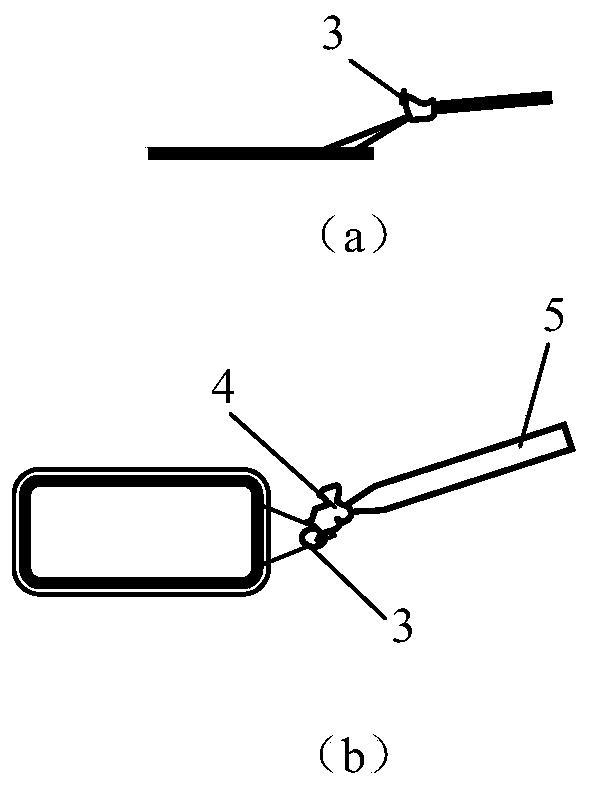

[0041] (1) if figure 2 As shown, manually add a little UV-curable glue on the needle tip, place it under an optical microscope, and use a nanomanipulator to place one end of an irregular single-particle sample with a maximum width of about 50 microns on the needle tip containing UV-curable glue, and the other end is suspended. , UV curable glue is cured by ultraviolet radiation to complete the partial suspension bonding and fixation of the single particle sample on the needle tip. The photo of using the nanomanipulator to bond the single particle sample to the needle tip containing UV-curable adhesive under the optical microscope is as follows: image 3 shown. The needle tip is an accessory of the atomic force microscope, which consists of a base and a t...

Embodiment 2

[0050] In this example, an optical microscope, a nanomanipulator and a double-beam electron microscope are combined to prepare micron-sized single-particle multiple TEM flake samples in situ, and the steps are as follows:

[0051] (1) Manually add a little UV-curable glue on the needle tip, place it under an optical microscope, and use a nanomanipulator to place one end of an irregular single-particle sample with a maximum width of about 40 microns on the needle tip containing UV-curable glue, and the other end is suspended , UV curable glue is cured by ultraviolet radiation to complete the partial suspension bonding and fixation of the single particle sample on the needle tip. The needle tip is an accessory of the atomic force microscope, which consists of a base and a triangular cantilevered needle tip located on the edge of the base. There is a certain angle between the cantilevered needle tip and the base, and the cantilevered needle tip has certain elasticity, such as fig...

Embodiment 3

[0065] In this example, an optical microscope, a nanomanipulator and a double-beam electron microscope are combined to prepare micron-sized single-particle multiple TEM flake samples in situ, and the steps are as follows:

[0066] (1) if figure 2 As shown, manually add a little UV-curable glue on the needle tip, place it under an optical microscope, use a nanomanipulator to place a part of the irregular single-particle sample with a maximum width of about 144 microns on the needle tip containing UV-curable glue, and the other part is suspended , UV curable glue is cured by ultraviolet radiation to complete the partial suspension bonding and fixation of the single particle sample on the needle tip. The needle tip is an accessory of the atomic force microscope, which consists of a base and a triangular cantilevered needle tip located on the edge of the base. There is a certain angle between the cantilevered needle tip and the base, and the cantilevered needle tip has certain el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com