Wire harness production and assembly system of digital electrical complete sets of products

An assembly system and production execution system technology, applied in the manufacture of wiring harnesses, electrical components, electrical digital data processing, etc., can solve the problems of inability to simulate the final assembly of electrical components, high requirements for designers, rework raw materials, etc., to save raw materials , Avoid wire harness waste, avoid waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

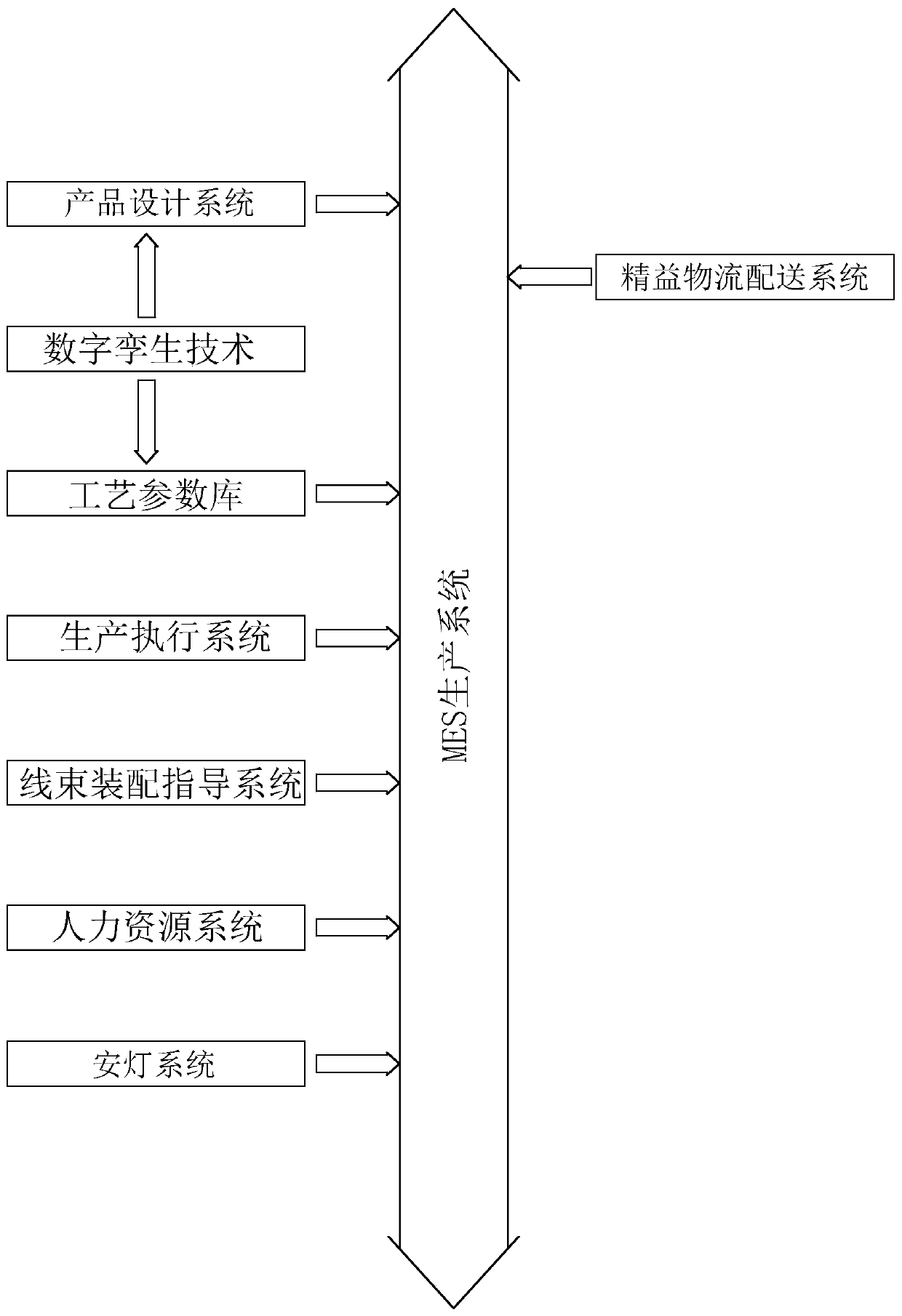

[0034] refer to figure 1 , which is a wire harness production and assembly system for a digital complete set of electrical products disclosed in the present invention, includes an MES system, and the MES system is connected with a product design system for wiring design of a complete set of electrical products. The product design system includes a three-dimensional wiring simulation software. In the present invention The 3D wiring simulation software can use Superworks of Lichi Company. The 3D wiring simulation software can design the installation position of electrical components in the power distribution cabinet and the corresponding wiring connections according to the electrical design drawings, so as to know the specifications of the required wiring harness. and the model number of the terminals at both ends of the harness.

[0035]The MES system is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com