Ebullated bed reactor cyclone self-priming distributor

A technology of ebullating bed reactors and distributors, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of inapplicability, inability to cut gas, and uniform bubbles, so as to avoid local inhomogeneity, The effect of increasing residence time and promoting gas-liquid mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

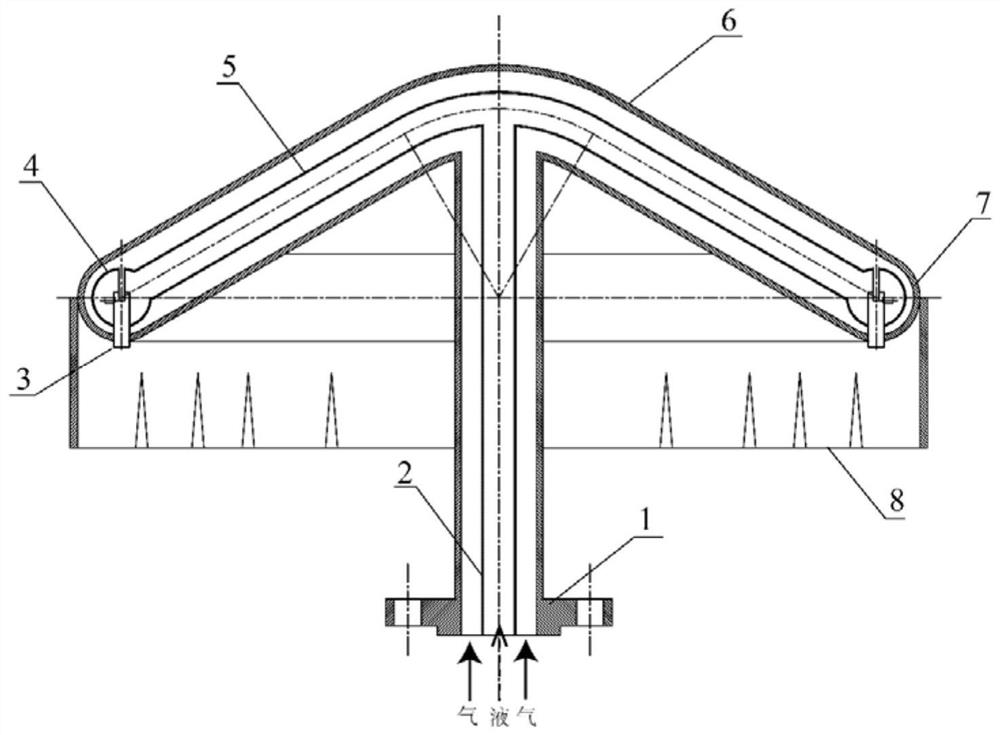

[0033] After extensive and in-depth research, the inventor of the present application has developed a cyclone self-priming distributor suitable for ebullating bed reactors, which has large operating flexibility and cutting The bubble scale is small, the gas-liquid two-phase distribution is uniform, and the pressure drop is small, which has high application value.

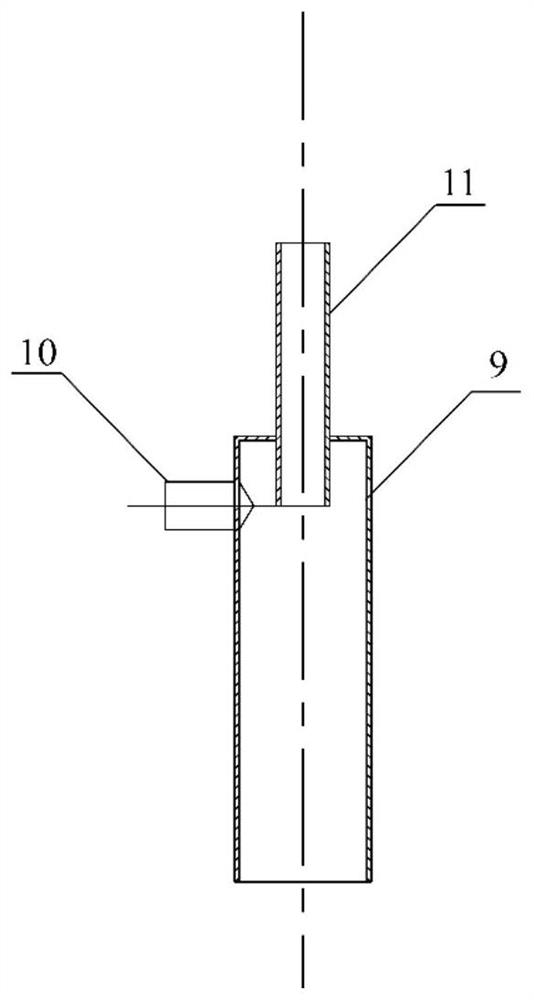

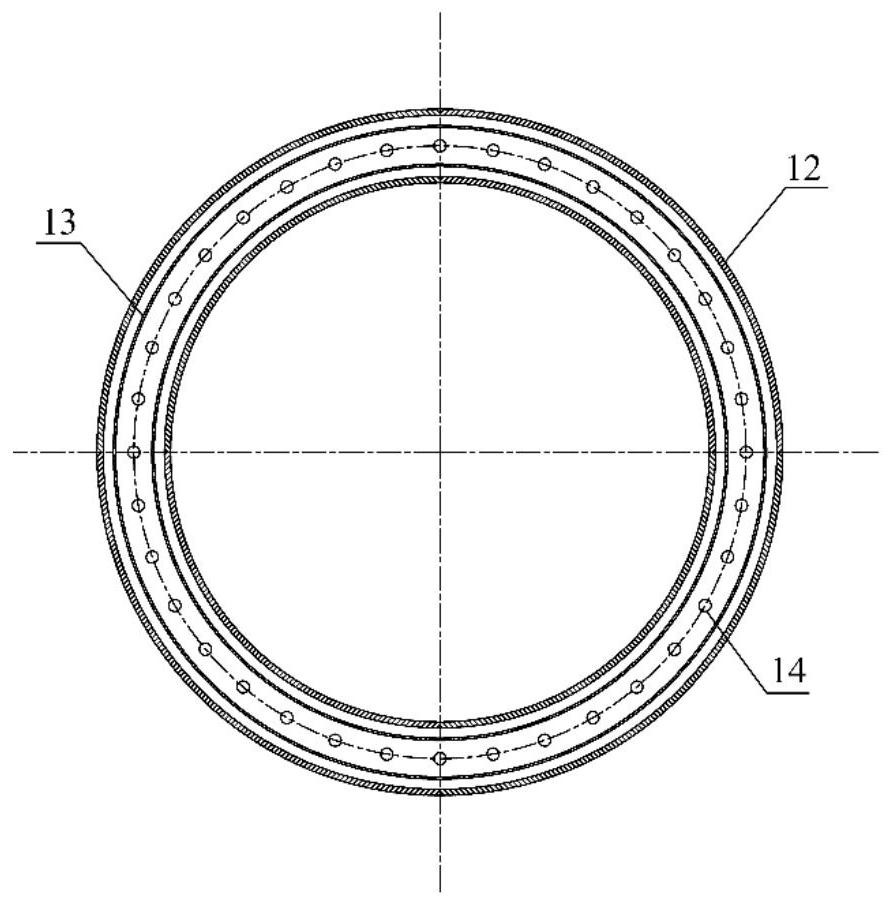

[0034] The disclosure provides a swirl self-priming distributor for an ebullated bed reactor, including: a gas inlet pipe, a liquid inlet pipe, a swirl self-suction nozzle, a liquid annular distribution pipe, a gas annular distribution pipe, a liquid branch pipe, a gas Branch pipe and skirt-like broken flow plate. The specific working principle is: the gas-liquid two-phase enters from the bottom inlet separately, the liquid phase goes through the inner pipe, the gas phase goes through the annulus between the outer pipe and the inner pipe, the gas-liquid two-phase enters through the inlet pipe and is distributed to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com