Powdery pencil lead and preparing method thereof

A pencil lead and pulverization technology, applied in the direction of pencil lead, non-active pencil, printing, etc., can solve the problems of not being able to wipe clean, poor softness, difficult to modify, etc., to achieve good erasable effect, good color saturation, color bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

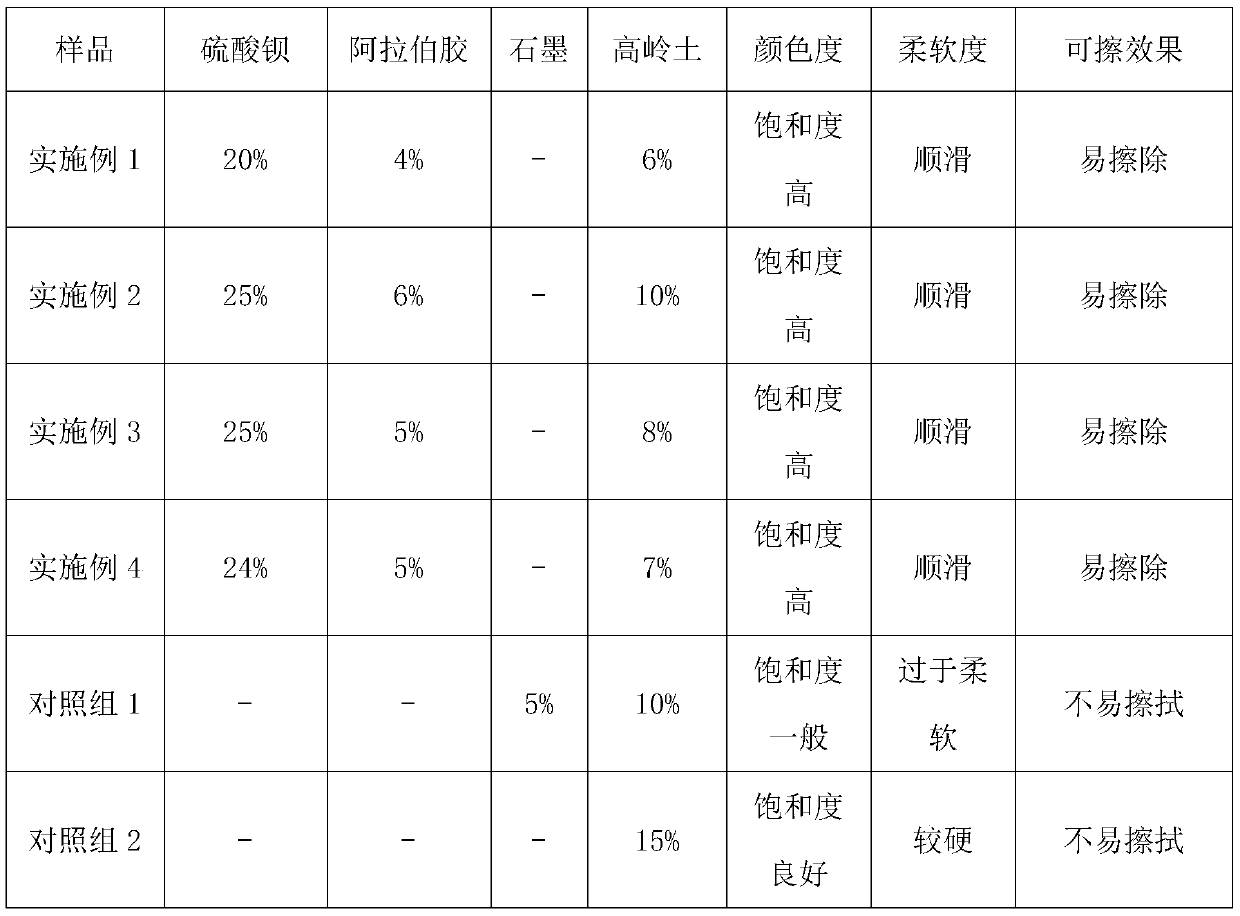

Embodiment 1

[0024] The powdered lead core in this embodiment is mainly prepared from the following raw materials in mass percentage: 30% of clay powder, 20% of barium sulfate, 6% of kaolin, 4% of gum arabic, and 28% of pigment. Also add other raw materials necessary for producing lead cores, such as water, in the raw materials. Select kaolin to be 1600 order kaolin micropowder in the present embodiment, clay powder is the clay powder more than 800 orders, barium sulfate is the barium sulfate powder more than 1000 orders, and gum arabic is pulvis. The pulverized pencil lead produced in this example had a length of 90 mm and a diameter of 3.0 mm.

[0025] Adopt the raw material consumption of present embodiment to carry out concrete pulverization pencil lead preparation, comprise the steps:

[0026] Step 1, mixing the washed clay, barium sulfate, kaolin, gum arabic and pigment into a uniform dry powder;

[0027] Step 2, kneading the dry powder evenly mixed in step 1, sealed storage and gr...

Embodiment 2

[0035] The pulverized lead core in the present embodiment is mainly prepared from the raw materials of following mass percentage: clay powder 35%, barium sulfate 25%, kaolin 10%, gum arabic 6%, pigment 32%, produced in the present embodiment The powdered pencil lead has a length of 185mm and a diameter of 7.0mm, and the preparation process is the same as in Example 1.

Embodiment 3

[0037] The pulverized lead core in the present embodiment is mainly prepared from the raw materials of following mass percentage: clay powder 30%, barium sulfate 25%, kaolin 8%, gum arabic 5%, pigment 32%, produced in the present embodiment The powdered pencil lead has a length of 100mm and a diameter of 5mm, and the preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com