Fine separation method and system of crude Fischer-Tropsch wax

A Fischer-Tropsch wax and fine separation technology, applied in separation methods, distillation separation, chemical instruments and methods, etc., can solve the problems of high risk, high melting point Fischer-Tropsch wax cannot be further separated, and the product use effect is not good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

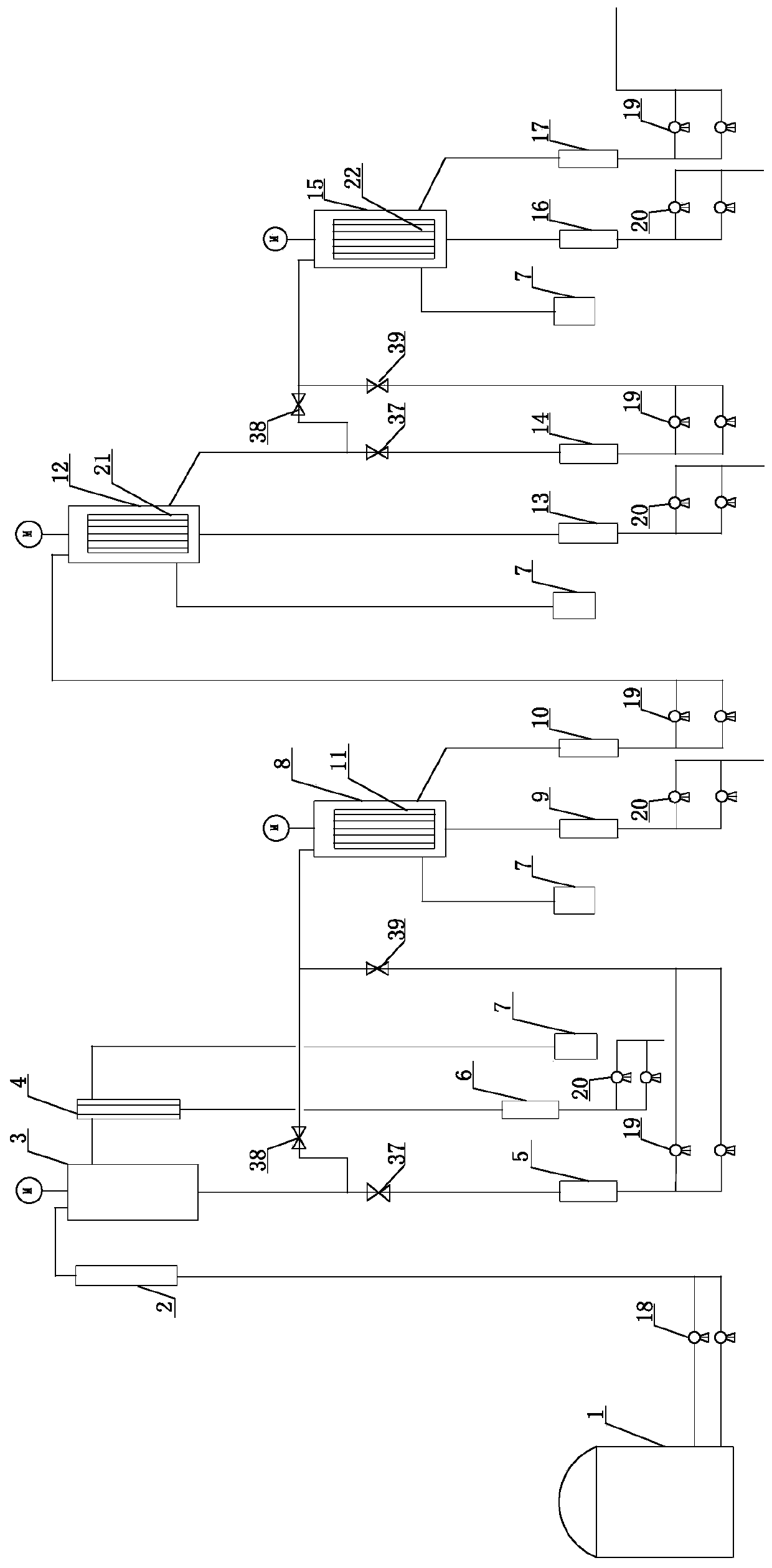

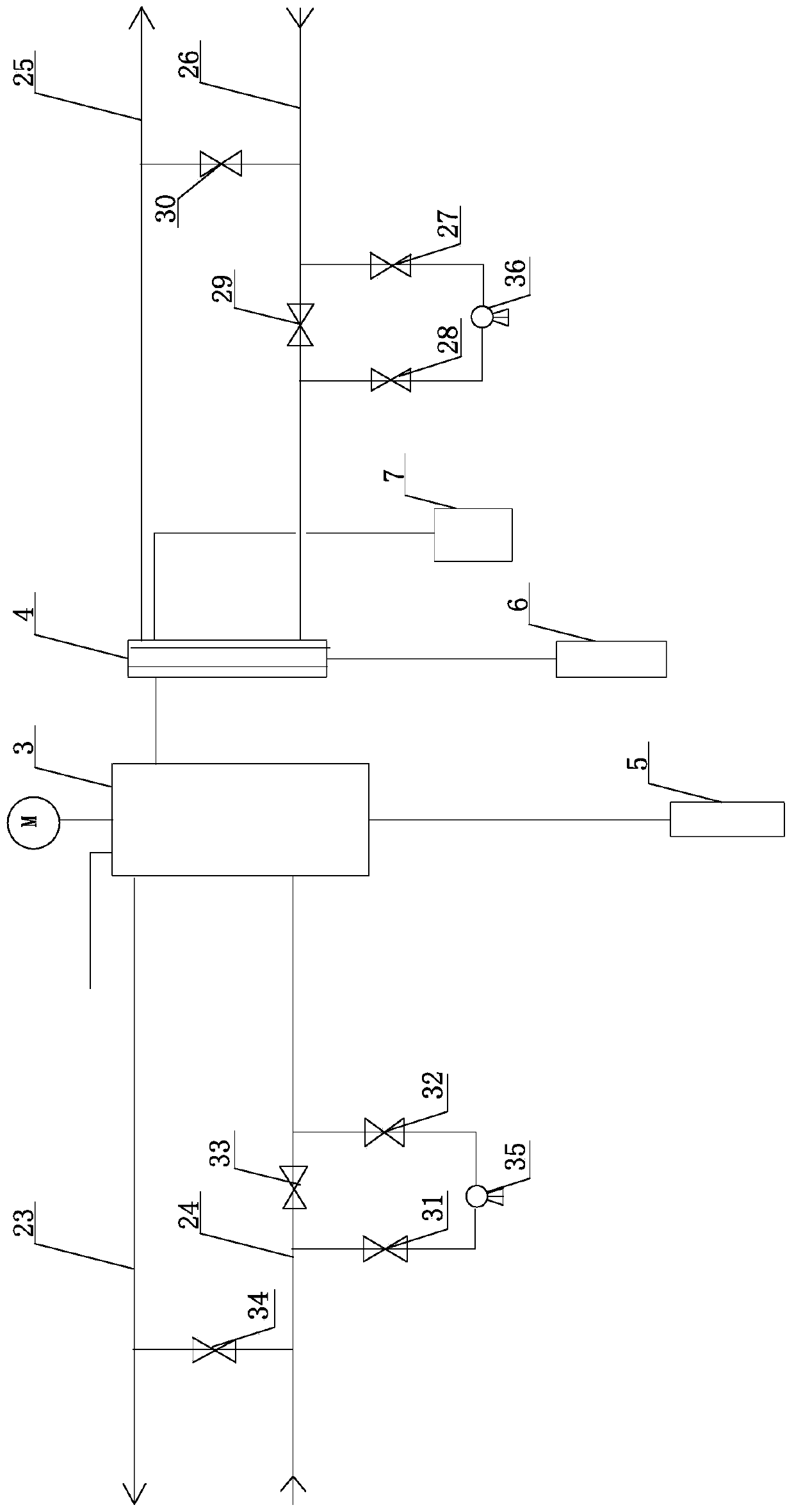

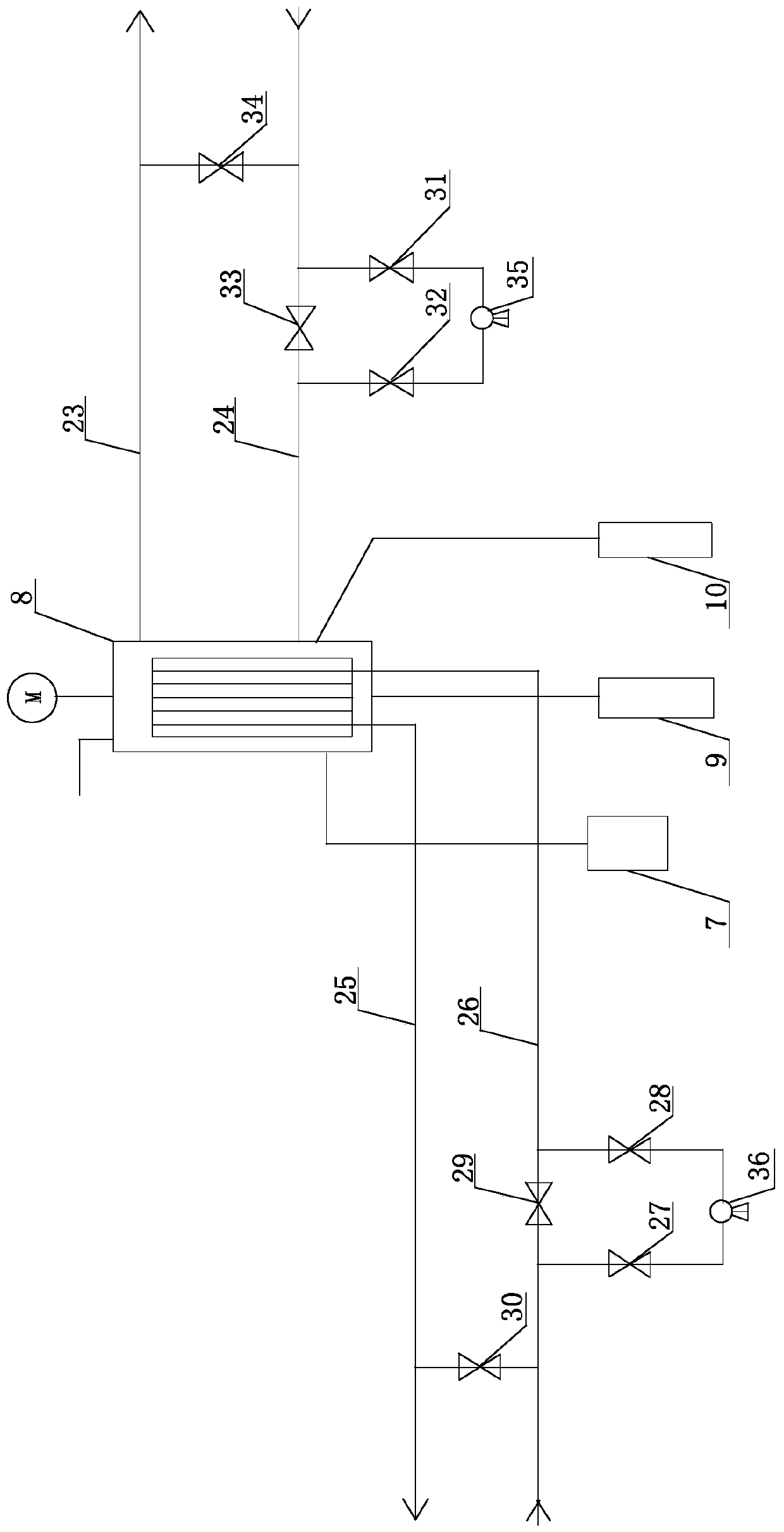

[0067] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0068] Such as figure 1As shown, the fine separation system of the Fischer-Tropsch wax crude product of the present invention comprises a Fischer-Tropsch wax crude product raw material storage tank 1, a primary separation system, a secondary separation system, a three-stage separation system and a four-stage separation system; The crude raw material storage tank 1 is connected to the thin-film evaporator 3 in the primary separation system through pipelines, and the 1# heavy phase collection tank 5 in the primary separation system is connected to the primary short-path distiller 8 in the secondary separation system through pipelines The 2# heavy phase collection tank 10 in the secondary separation system is connected with the secondary short-path distiller 12 in the tertiary separation system through pipelines, and the 3# heavy phase collection tank 14 in the ter...

Embodiment 2

[0095] The refined separation system of the Fischer-Tropsch wax crude product used in Example 2 is the same as that in Example 1.

[0096] The fine separation method of the Fischer-Tropsch wax crude product described in present embodiment 2, specifically as follows:

[0097] The raw material is Fischer-Tropsch wax crude product with high melting point, the drop melting point is between 85-100°C, the normal paraffin content is over 85%, and the carbon number distribution is between C15-C85.

[0098] Fischer-Tropsch wax raw material enters the primary separation system and is separated in the thin film evaporator to obtain 1# light phase product and 1# heavy phase product of C15-C32, and the 1# heavy phase product enters the secondary separation system. Separation is carried out in the distiller to obtain 2# light phase products and 2# heavy phase products of C17-C40. The 2# heavy phase products enter the three-stage separation system and are separated in the secondary short-pat...

Embodiment 3

[0106] The refined separation system of the Fischer-Tropsch wax crude product used in Example 3 is the same as that in Example 1.

[0107] The fine separation method of the Fischer-Tropsch wax crude product described in present embodiment 3, specifically as follows:

[0108] The raw material is Fischer-Tropsch wax crude product with high melting point, the dropping melting point is between 85-100°C, the normal paraffin content is over 85%, and the carbon number distribution is between C13-C90.

[0109] Fischer-Tropsch wax crude raw material enters the primary separation system and is separated in the thin film evaporator to obtain 1# light phase product and 1# heavy phase product of C13-C35, and the 1# heavy phase product enters the secondary separation system. Separation is carried out in the distiller to obtain 2# light phase product and 2# heavy phase product of C20-C45, and the 2# heavy phase product enters the three-stage separation system and is separated in the secondar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drop melting point | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com