Asparagus extract as well as preparation method and application thereof

An asparagus extract and asparagus technology are applied in the field of asparagus extract and its preparation, which can solve the problems of affecting drug efficacy and low content, and achieve the effect of improving the level of intestinal flora.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

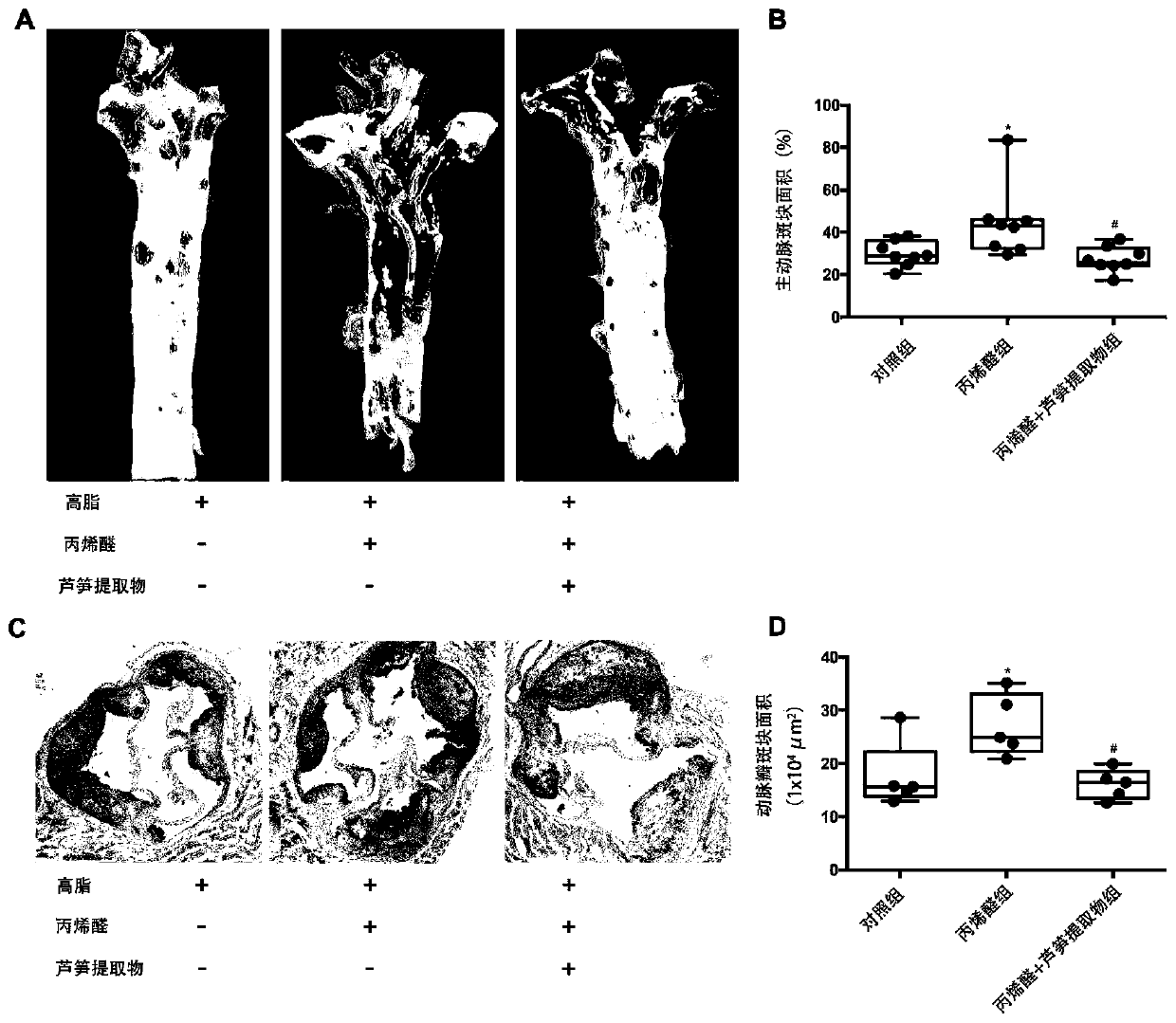

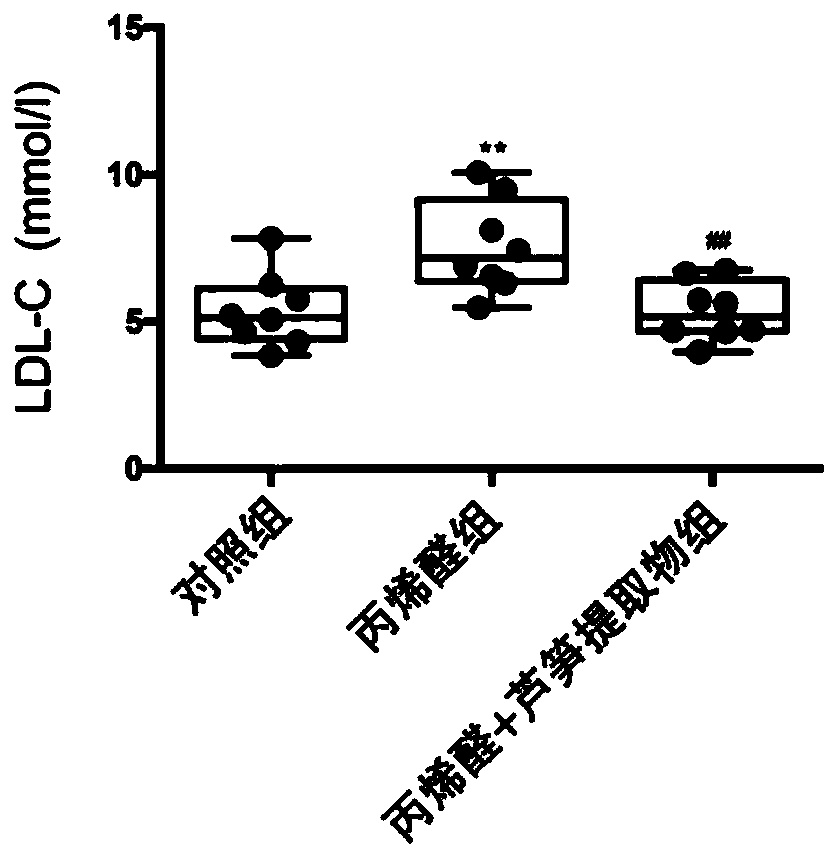

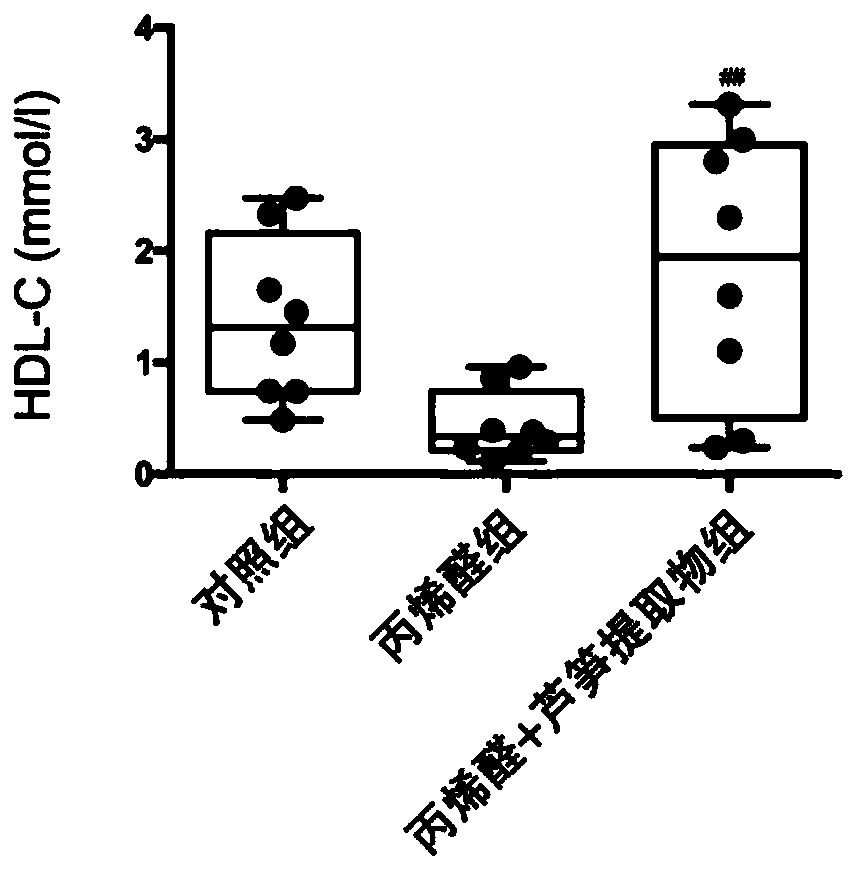

Image

Examples

Embodiment 1

[0076] A kind of preparation of asparagus extract:

[0077] 1) Dry and crush 20g of asparagus raw material, pass through a 10-mesh sieve, adjust the pH value to 4, add cellulase and pectinase to the asparagus raw material according to the mass ratio of 1:1 for enzymolysis, cellulase and pectinase The total mass of the asparagus is 0.1% of the asparagus raw material, add 10 times the amount of water for microwave-assisted extraction, microwave power 100w, enzymolysis temperature 30°C, enzymolysis time 1h, filter to obtain filtrate 1 and filtrate A;

[0078] 2) Filtrate A is ultrasonically assisted with a mixed solvent of acetone and 70% ethanol by volume fraction, the volume ratio of ethanol and acetone is 1:1, and the mass volume ratio of filtrate A and mixed solvent is 1:5g / mL, ultrasonic time 0.5h, ultrasonic power 50w, filter to obtain filtrate 2 and filtrate B;

[0079] 3) The filtrate B is extracted with a mixed solvent of normal hexane and ethanol with a volume fractio...

Embodiment 2

[0083] A kind of preparation of asparagus extract:

[0084] 1) Dry and crush 20g of asparagus raw material, pass through a 60-mesh sieve, adjust the pH value to 6, add cellulase and pectinase to the asparagus raw material according to the mass ratio of 3:1 for enzymolysis, cellulase and pectinase The total mass of the asparagus was 5% of the raw material of asparagus, and 30 times the amount of water was added for microwave-assisted extraction, the microwave power was 300w, the enzymolysis temperature was 60°C, and the enzymolysis time was 5h, and filtered to obtain filtrate 1 and filtrate A;

[0085] 2) the filtrate A is ultrasonically assisted with a mixed solvent of acetone and a volume fraction of 90% ethanol, the volume ratio of ethanol and acetone is 3:1, and the mass volume ratio of filtrate A and the mixed solvent is 1:35g / mL, ultrasonic time 3h, ultrasonic power 200w, filter, repeat extraction 3 times, and combine to obtain filtrate 2 and filtrate B;

[0086] 3) The...

Embodiment 3

[0090] A kind of preparation of asparagus extract:

[0091] 1) Dry and crush 20g of asparagus raw material, pass through a 30-mesh sieve, adjust the pH value to 5, add cellulase and pectinase to the asparagus raw material according to the mass ratio of 2:1 for enzymolysis, cellulase and pectinase The total mass of the asparagus was 2% of the raw material of asparagus, and 15 times the amount of water was added for microwave-assisted extraction, the microwave power was 200w, the enzymolysis temperature was 45°C, and the enzymolysis time was 3h, and filtered to obtain filtrate 1 and filtrate A;

[0092] 2) the filtrate A is ultrasonically assisted with a mixed solvent of 80% ethanol with acetone and volume fraction, the volume ratio of ethanol and acetone is 2:1, and the mass volume ratio of filtrate A and mixed solvent is 1:15g / mL, ultrasonic time 2h, ultrasonic power 150w, filter, repeat extraction twice, and combine to obtain filtrate 2 and filtrate B;

[0093] 3) The filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com