A method for improving the adsorption capacity of powdery chitin to enzyme protein and its application

A technology of chitin and chitin-binding domain, which is applied in the field of chitin fiber preparation, can solve the problems of environmental pollution, harsh preparation conditions, long preparation period and the like, and achieves improved protein adsorption performance, short preparation period and simple steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Screening of chitin powder

[0036] A 100-mesh sieve was used to sieve chitin powder with a uniform diameter of 100 mesh from chitin powders with different particle sizes. The chitin powder was purchased from Aladdin (Shanghai) Co., Ltd.

Embodiment 2

[0037] Example 2 Preparation of Chitin Suspension

[0038] The 100-mesh chitin powder sieved in Example 1 was washed three times with pure water, and dried in an oven at 65°C. Weigh 2 grams of dried chitin powder and add distilled water until the final concentration of chitin powder is 2% to prepare chitin suspension.

Embodiment 3

[0039] Example 3 Preparation of chitin nanofibers

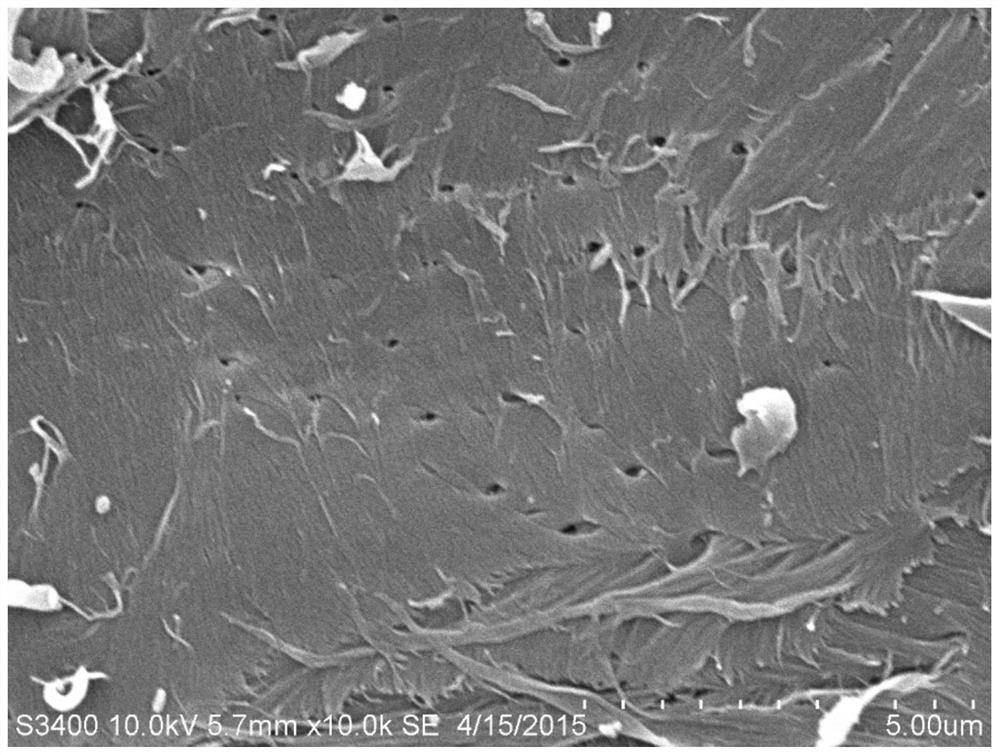

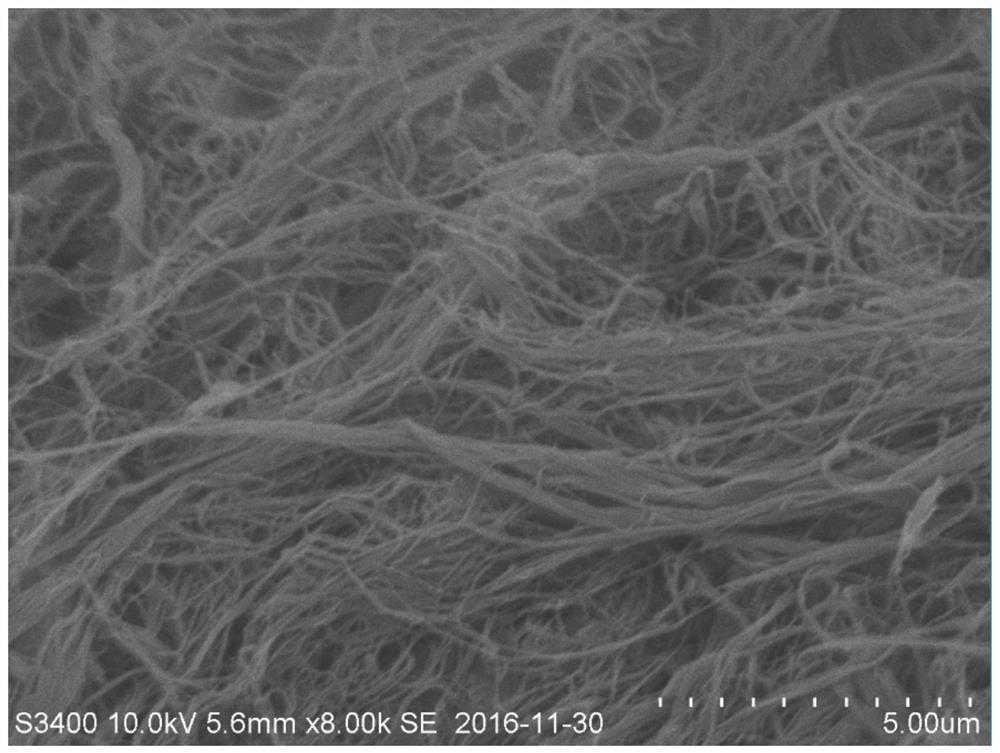

[0040] With the chitin suspension obtained in Example 2, the feed rate of the high-pressure homogenizer is set to be 15L / h, and the pressure parameter of the high-pressure homogenizer is set at this feed rate to be 600bar, and the chitin suspension After 5 cycles of average treatment, the suspension of chitin nanofibers was prepared. figure 1 and figure 2 The SEM images of chitin before and after treatment are respectively. It can be clearly compared in the figure that the chitin treated with high pressure homogenization has finer nano whiskers. figure 1 The surface of chitin under medium SEM has a rough sheet structure with small holes in it, which is not conducive to the adsorption of enzyme proteins; figure 2 The chitin fibers processed by a high-pressure homogenizer under medium SEM have a diameter distribution of 50nm-100nm, and this nanofiber structure can absorb more enzyme proteins.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com