Tailing dust processing device and method for rice processing

A technology for rice processing and processing methods, applied in chemical instruments and methods, grain processing, separation methods, etc., can solve the problems of workers' respiratory tract damage, easily polluted finished rice, tail dust treatment, etc., to reduce respiratory tract damage and reduce dust floating. phenomenon, the effect of reducing contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

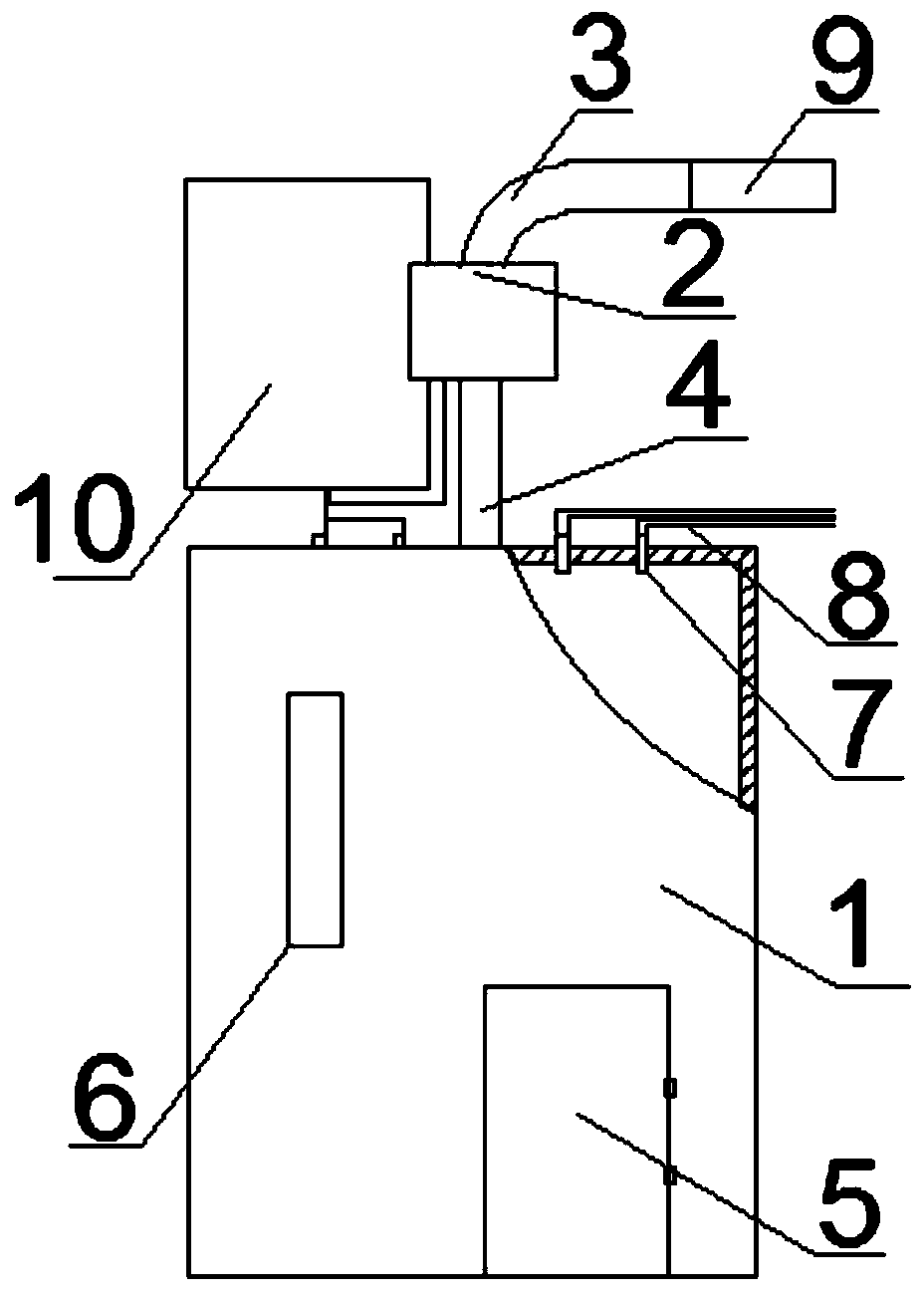

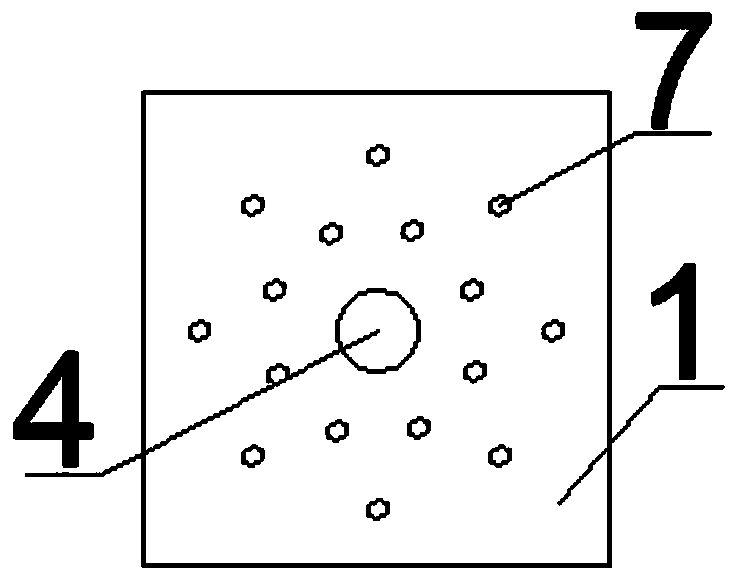

[0029] see Figure 1-2 , a tail dust treatment device for rice processing, comprising an electric control box 10, a bran outlet pipe 3, a collection pipe 4 and a collection box 1, and a negative pressure pump 2, and one end of the bran outlet pipe 3 is connected to a rice mill or The bran outlet 9 of the polishing machine is connected, and the other end of the bran outlet pipe 3 is connected with the top of the negative pressure pump 2, the bottom end of the negative pressure pump 2 is connected with the collection pipe 4, and the collection pipe 4 tail end is connected with the collection pipe 4. The box 1 is connected, the collection box 1 is a cuboid structure, and the top of its inner wall is equipped with an atomizing nozzle 7, and the front of the collection box 1 is provided with a discharge port 5 and an observation port 6; the negative pressure pump 2 and the mist Chemical nozzle 7 is all electrically connected with electric control box 10;

[0030] Described atomizi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com