Electric heat conduction device for self-pressing riveting

A technology of self-piercing riveting and conducting device, which is applied in the field of automobile body manufacturing, can solve the problems of difficulty in forming effective joints, difficulty in plastic deformation, influence of riveting gun heads, etc., and achieves the effects of improving connection quality, compact and lightweight device, and easy disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

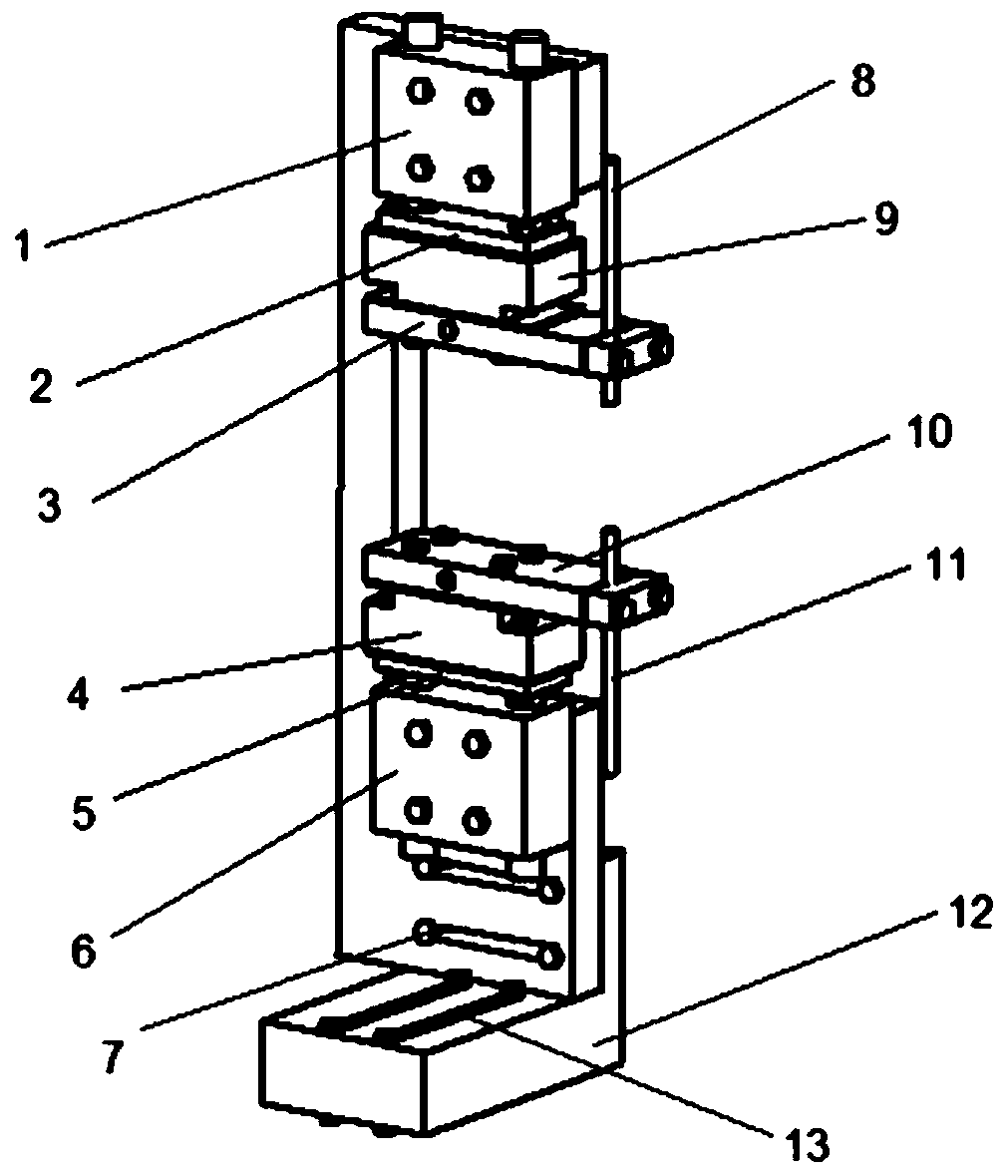

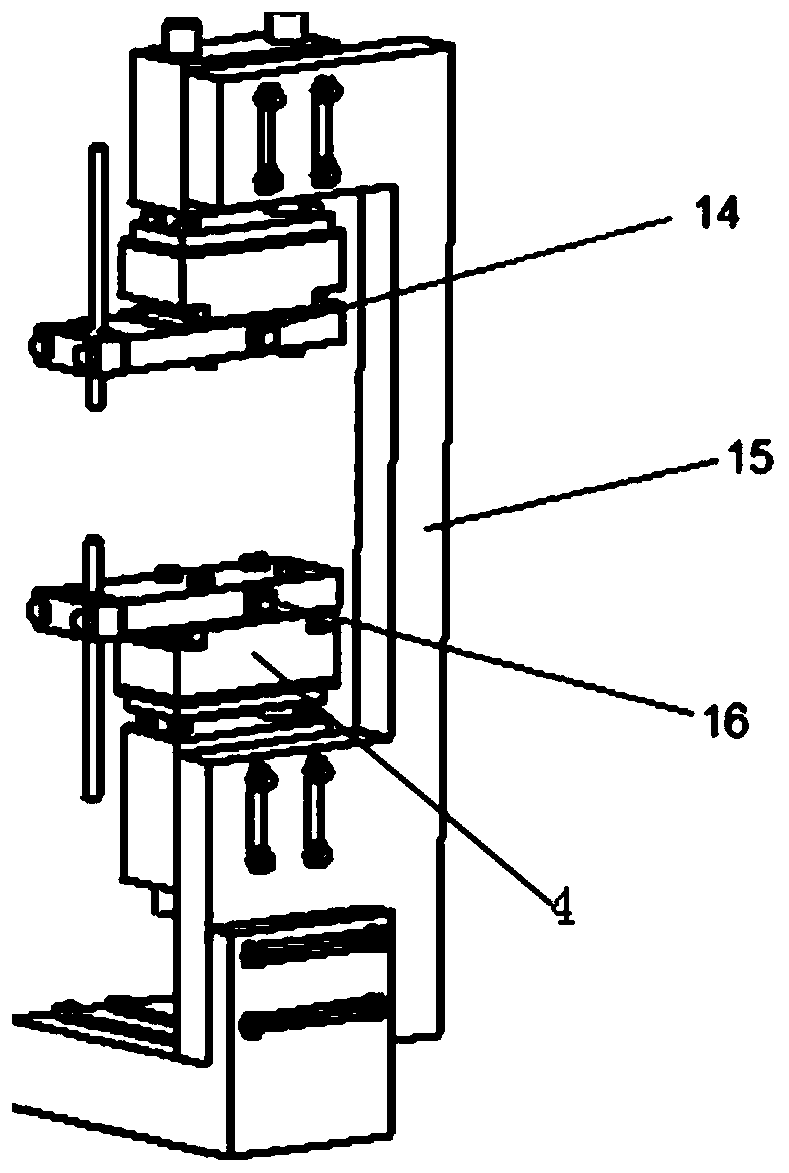

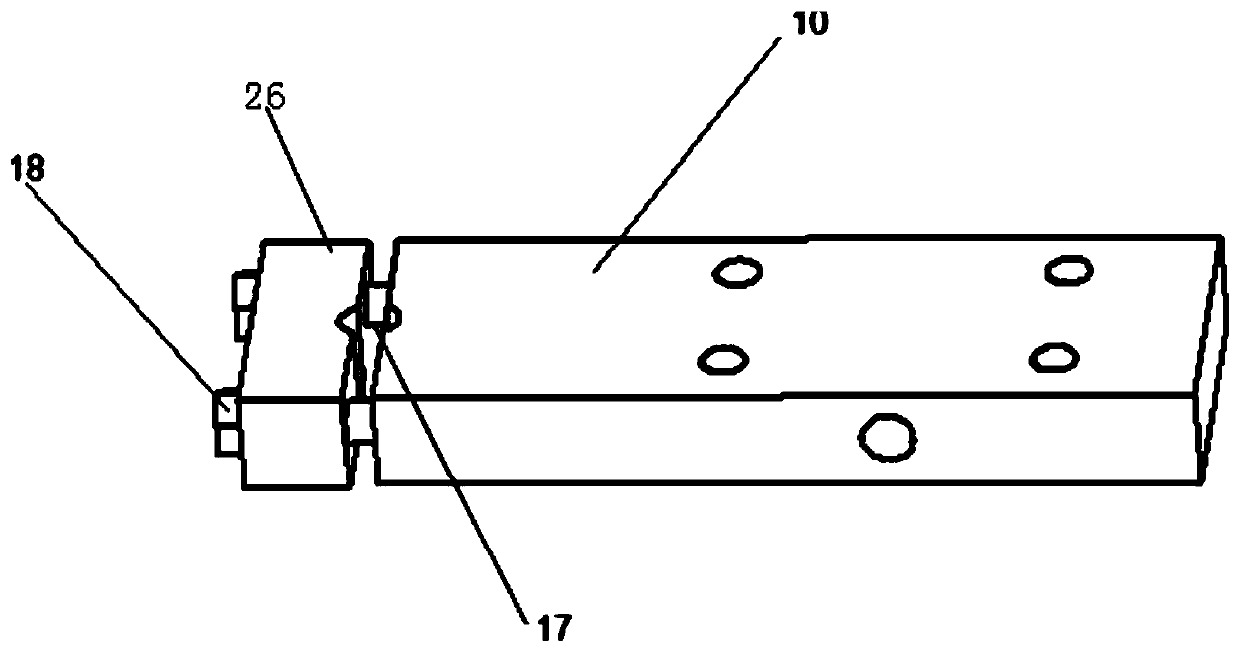

[0028] like Figure 1-9 As shown, the present invention provides a technical solution: an electric heat conduction device for self-piercing riveting, including a base 12 and a bracket 15, the bracket 15 is located at the upper end of the base 12, and the upper and lower ends of the bracket 15 are respectively connected with upper The cylinder 1 and the lower cylinder 6, the upper cylinder 1 and the lower cylinder 6 are symmetrically arranged, the upper cylinder guide rod base 2 and the lower cylinder guide rod base 5 are respectively installed on the upper cylinder 1 and the lower cylinder 6, and the upper cylinder guide rod base 5 is installed respectively. The cylinder guide rod base 2 and the lower cylinder guide rod base 5 are respectively connected with the upper cylinder 1 and the lower cylinder 6 through the guide rod base connecting hole 24, and the upper cylinder guide rod base 2 and the lower cylinder guide rod base 5 are respectively connected with The upper red cop...

Embodiment 2

[0032] like Figure 1-9 It is basically the same as Example 1, and further, when the thickness of the aluminum plate becomes 2 mm, since the overall thickness of the thin plate to be riveted becomes larger, it is necessary to rotate the second bolt on the side of the upper copper plate 3 and the lower copper plate 10. Adjust the clamping holes 17 of the 18 pairs, and re-adjust the positions of the upper and lower carbon rods 8 and 11, so that when the cylinder guide rod reaches the maximum stroke, the upper carbon rods 8 and 11 are respectively pressed against the upper and lower sides of the riveting point. , After the adjustment is completed, turn on the switch of the external control cabinet, the upper cylinder 1 and the lower cylinder 6 work at the same time, at this time, the upper brush 14 and the lower brush 16 are energized for 1.2s, and a strong current is applied to the plate to be riveted. The switch of the external source control cabinet is turned off, the air cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com