A kind of processing technology of pen cap

A processing technology and pen cap technology, which is used in writing connectors, printing, writing utensils and other directions to achieve the effects of high hardness, high processing efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

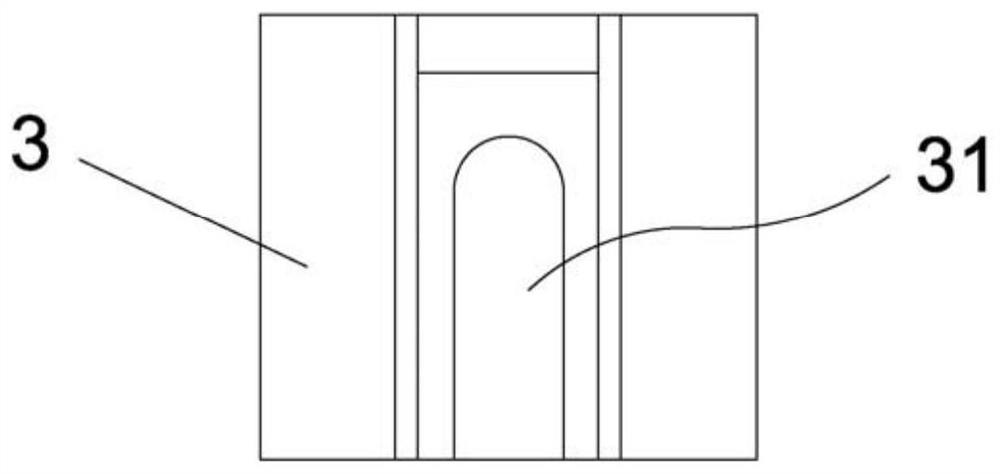

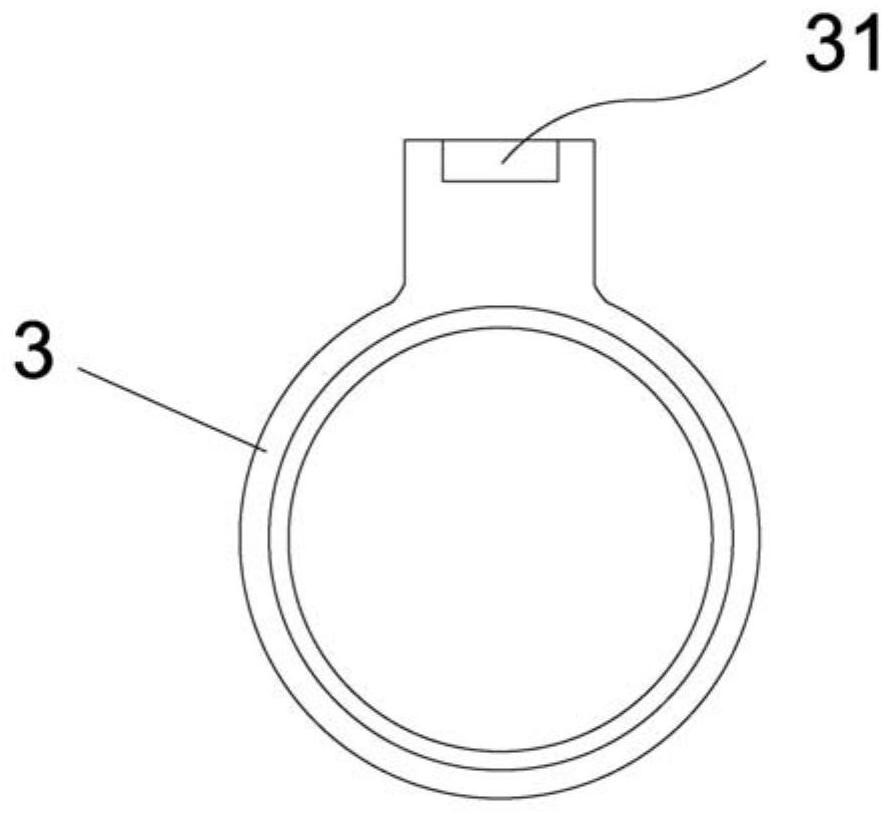

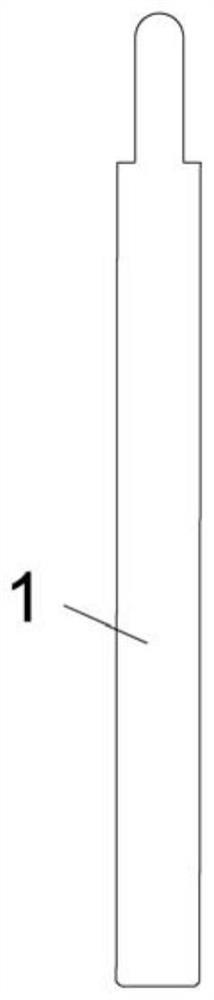

[0041] Such as Figure 1-8 Shown:

[0042] A processing technology for a pen cap, comprising the following steps:

[0043] The production of S11 shrapnel includes the following steps:

[0044] a1 Stamping: Prepare the first alloy sheet, place the first alloy sheet in a punching machine, punch out the shape according to the standard specification, and obtain the semi-finished shrapnel;

[0045] a2CNC: use a milling cutter to mill out the first installation groove 11 on the inner side of the pre-assembled shrapnel semi-finished product;

[0046] a3 cleaning: the shrapnel 1 is obtained after cleaning and drying.

[0047] S12 convex hull production includes the following steps:

[0048] b1 Turning: preparing the second alloy sheet, placing the second alloy sheet in a lathe, and cutting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com