Double-layer co-extrusion anti-polarization type EVA (ethylene-vinyl-acetate) composite adhesive film and preparation method thereof

A double-layer co-extrusion and anti-polarization technology, which is applied in the direction of chemical instruments and methods, layered products, and other household appliances, to achieve good compatibility, improved anti-PID performance, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

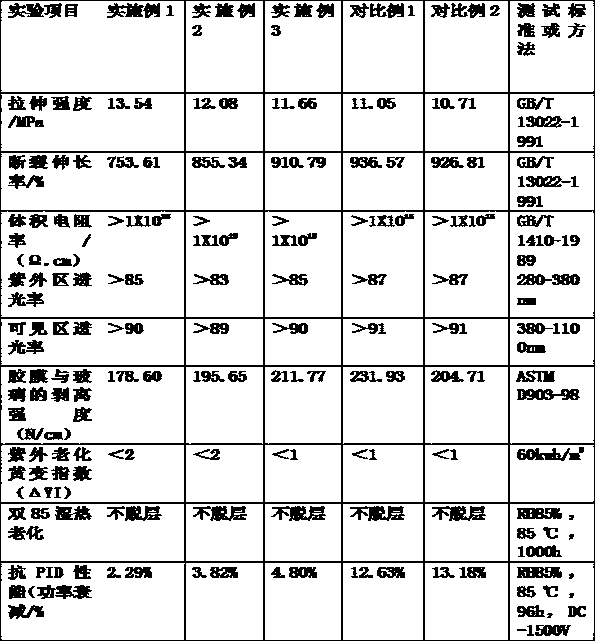

Examples

Embodiment 1

[0023] (1) Add the measured EAA resin (25% acrylate content, 69°C melting point, and 8.5g / 10min melt index) into the first horizontal mixer; then add the measured and evenly mixed The mixed liquid of initiator, co-crosslinking agent, coupling agent, UV stabilizer, UV absorber and antioxidant is evenly sprayed into the resin particles through the liquid spraying device, stirring while spraying, stirring speed 5r / min, metering Spray for 10 minutes, and keep the horizontal mixer at a constant temperature of 40-50°C during the spraying process; after spraying, increase the stirring speed to 12r / min, first rotate forward for 20 minutes, then reverse for 20 minutes, so that the liquid mixing aid is completely absorbed The resin particles are absorbed, and the horizontal mixer is kept at a constant temperature of 40-50°C during the stirring process. At the same time, the measured EVA resin (melt flow rate is 25g / 10min, light transmittance> 86%, volume resistivity ≥ 1.0×10 14 , the m...

Embodiment 2

[0026] (1) Add the measured EMA resin (30% acrylate content, 61°C melting point, 4g / 10min melt index) into the first horizontal mixer; The mixed liquid of agent, co-crosslinking agent, coupling agent, ultraviolet stabilizer, ultraviolet absorber and antioxidant is evenly sprayed into the resin particles through the liquid spraying device, stirring while spraying, stirring speed 8r / min, metered spraying 10min, keep the horizontal mixer at a constant temperature of 40-50°C during the spraying process; after the spraying, increase the stirring speed to 18r / min, first rotate forward for 15min, then reversely stir for 15min, so that the liquid mixing aid is completely covered by the resin Particle absorption, keep the horizontal mixer at a constant temperature of 40-50°C during the stirring process. At the same time, the measured EVA resin (melt flow rate is 20g / 10min, light transmittance> 86%, volume resistivity ≥ 1.0×10 14 , melting temperature is 54°C, VA content 25%) into the ...

Embodiment 3

[0029] (1) Add the measured PTW resin (acrylate content 25.5%, melting point 73°C, melt index 12g / 10min) into the first horizontal mixer; The mixed liquid of agent, co-crosslinking agent, coupling agent, ultraviolet stabilizer, ultraviolet absorber and antioxidant is evenly sprayed into the resin particles through the liquid spraying device, stirring while spraying, stirring speed 5r / min, metered spraying 10min, keep the constant temperature of the horizontal mixer at 40-50°C during the spraying process; after the spraying, increase the stirring speed to 15r / min, first rotate forward and stir for 15min, then reversely stir for 15min, so that the liquid mixing aid is completely covered by the resin Particle absorption, keep the horizontal mixer at a constant temperature of 40-50°C during the stirring process. At the same time, the measured EVA resin (melt flow rate is 20g / 10min, light transmittance> 86%, volume resistivity ≥ 1.0×10 14 , melting temperature is 54°C, VA content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com