Material separating mechanism and conveying system thereof for bagged material

A material-distributing mechanism and material-distributing technology, applied in the direction of mechanical conveyors, conveyors, conveyor objects, etc., can solve the problems of high installation site requirements and large volume, etc., to improve work efficiency, good material distribution effect, and guarantee The effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

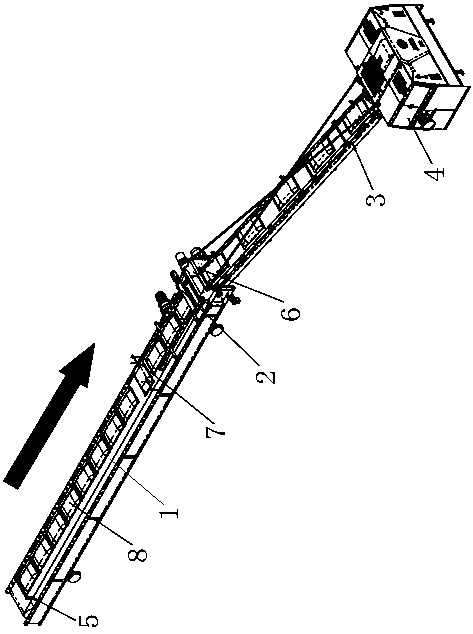

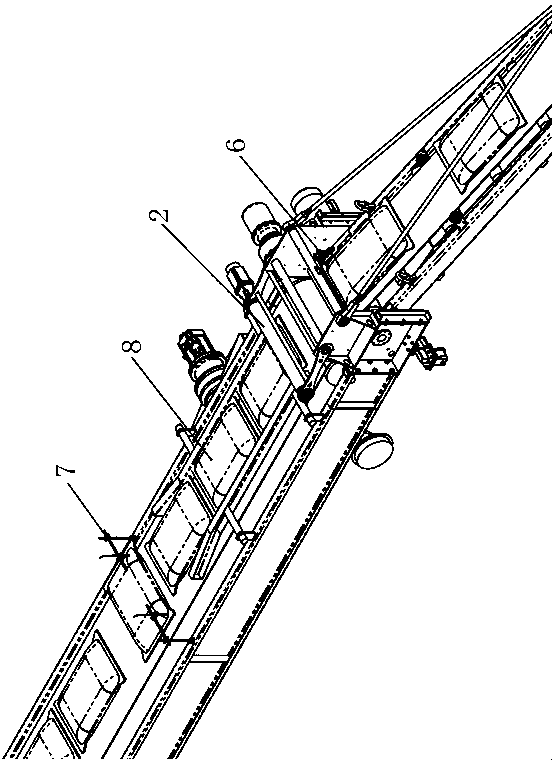

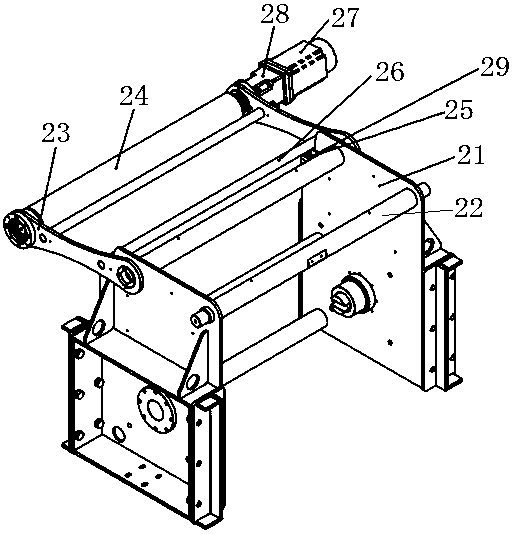

[0061] As shown in the figure, the bagged material conveying system of this embodiment includes a first conveying line, a bagged material distributing mechanism, a second conveying line, a stacker head, a detection sensor at the feed end, a detection sensor at the discharge end, a horizontal Pack detection sensor, second control system. Among them, the first conveying line, the bagged material distributing mechanism, the second conveying line, and the stacking head are connected in sequence, and the bagged materials entering from the first conveying line are distributed through the bagged material distributing mechanism, and the second After the conveying line is conveyed, it enters the palletizer head for processing. The first conveying line and the second conveying line respectively adopt belt conveying lines; Inside the palletizer head.

[0062] The detection sensor at the feed end and the horizontal bag detection sensor are respectively arranged on the first conveying lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com