Preparation method of organic metal framework-coated two-dimensional black phosphorus nanosheets

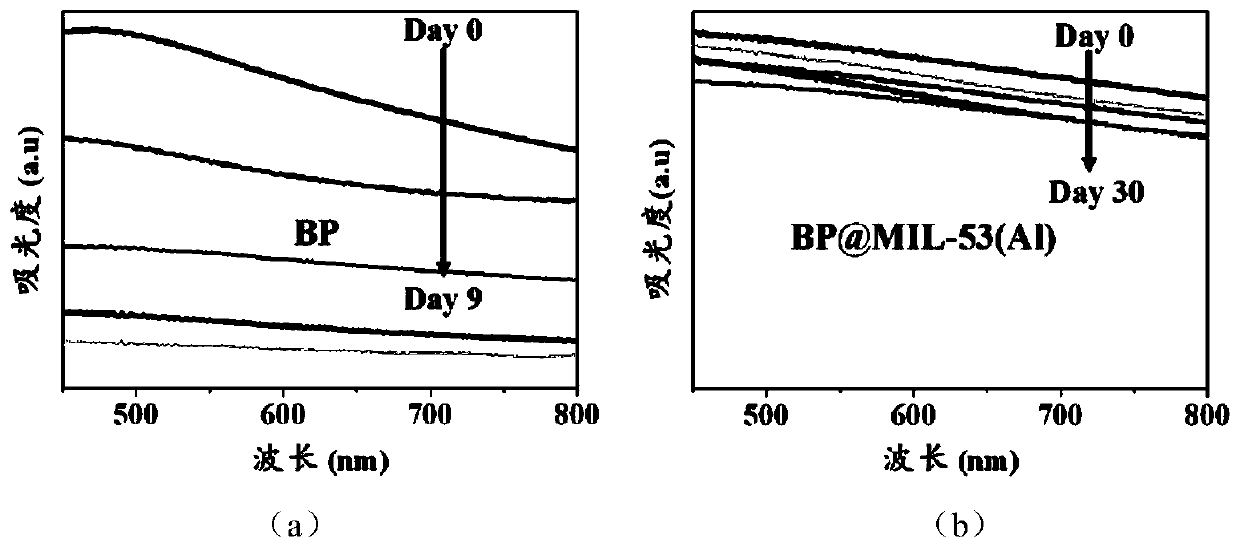

An organic metal and nanosheet technology, applied in the field of black phosphorus nanosheets, can solve the problems of harsh experimental conditions, destroying the two-dimensional structure of black phosphorus, and complicated methods, and achieve the effect of improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

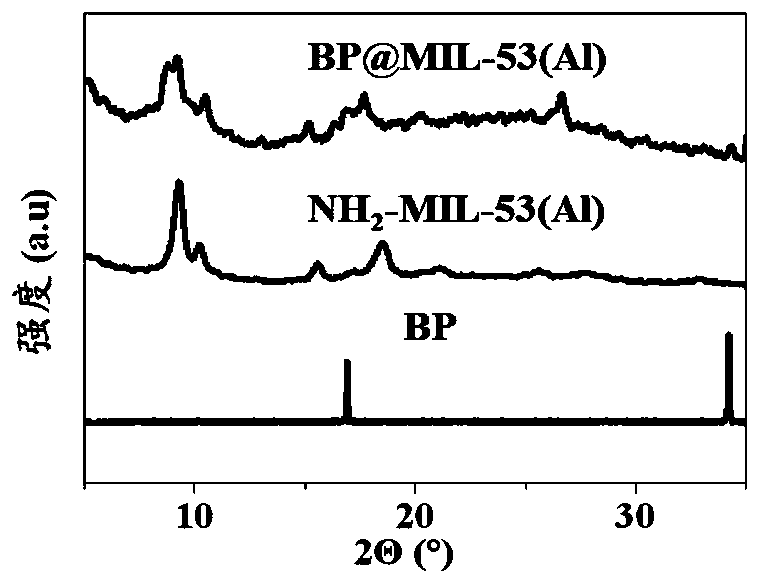

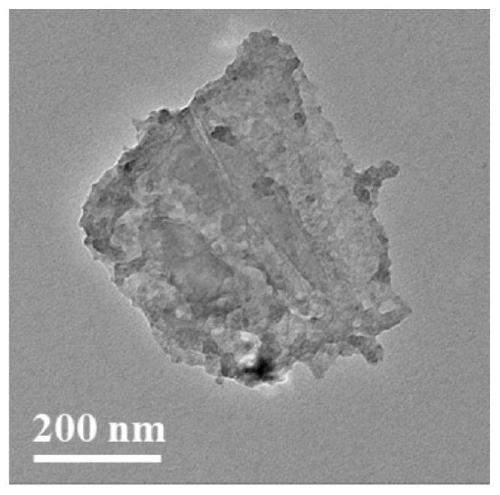

[0027] This embodiment provides an organometallic framework NH 2 -MIL-53 (Al) the method for coating black phosphorus, comprises the following steps:

[0028] (1) Weigh 60 mg of black phosphorus in anaerobic environment and grind it in 0.1 mg / mL PVP aqueous solution; use a 950W probe to sonicate in a low-temperature water bath for 5 h; take the dispersion and centrifuge at 4000 rpm for 10 min to get the supernatant, the The supernatant was centrifuged at 12000rpm for 6min to collect the precipitate, and then the precipitate was dispersed in absolute ethanol to repeat the centrifugation step, and finally two-dimensional black phosphorus nanosheets (marked as BP) were obtained.

[0029] (2) Take a certain amount of anhydrous aluminum chloride and dissolve it in absolute ethanol, and the concentration is 8mmol / L; the two-dimensional black phosphorus nanosheets in step (1) are redispersed in the ethanol solution of aluminum chloride, Then stir overnight.

[0030] (3) After dryin...

Embodiment 2

[0036] The present embodiment provides a kind of method that organic metal framework MIL-53 (Fe) coats black phosphorus, comprises the following steps:

[0037] (1) Weigh 60 mg of black phosphorus in anaerobic environment and grind it in 0.1 mg / mL PVP aqueous solution; use a 950W probe to sonicate in a low-temperature water bath for 5 h; take the dispersion and centrifuge at 4000 rpm for 10 min to get the supernatant, the The supernatant was centrifuged at 12000rpm for 6min to collect the precipitate, and then the precipitate was dispersed in absolute ethanol to repeat the centrifugation step, and finally two-dimensional black phosphorus nanosheets (marked as BP) were obtained.

[0038](2) take a certain amount of anhydrous zinc chloride and dissolve it in absolute ethanol, and the concentration is 8mmol / L; the two-dimensional black phosphorus nanosheets in step (1) are redispersed in the ethanol solution of zinc chloride, Then stir overnight.

[0039] (3) The dispersion liqu...

Embodiment 3

[0043] This embodiment provides a method for coating black phosphorus with an organic metal framework ZIF-8, comprising the following steps:

[0044] (1) Weigh 60 mg of black phosphorus in anaerobic environment and grind it in 0.1 mg / mL PVP aqueous solution; use a 950W probe to sonicate in a low-temperature water bath for 5 h; take the dispersion and centrifuge at 4000 rpm for 10 min to get the supernatant, the The supernatant was centrifuged at 12000rpm for 6min to collect the precipitate, and then the precipitate was dispersed in absolute ethanol to repeat the centrifugation step, and finally two-dimensional black phosphorus nanosheets (marked as BP) were obtained.

[0045] (2) take a certain amount of anhydrous zinc chloride and dissolve it in absolute ethanol, and the concentration is 8mmol / L; the two-dimensional black phosphorus nanosheets in step (1) are redispersed in the ethanol solution of zinc chloride, Then stir overnight.

[0046] (3) After drying the dispersion i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com