Integrated reactor for removing trace antibiotics in composite polluted surface water and removing method of integrated reactor

A technology for compound pollution and surface water, applied in the field of environmental pollution control, can solve the problems of limited removal capacity of trace organics with small molecular weight, etc., and achieve the effects of low operating cost, high degree of automation, and improved removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

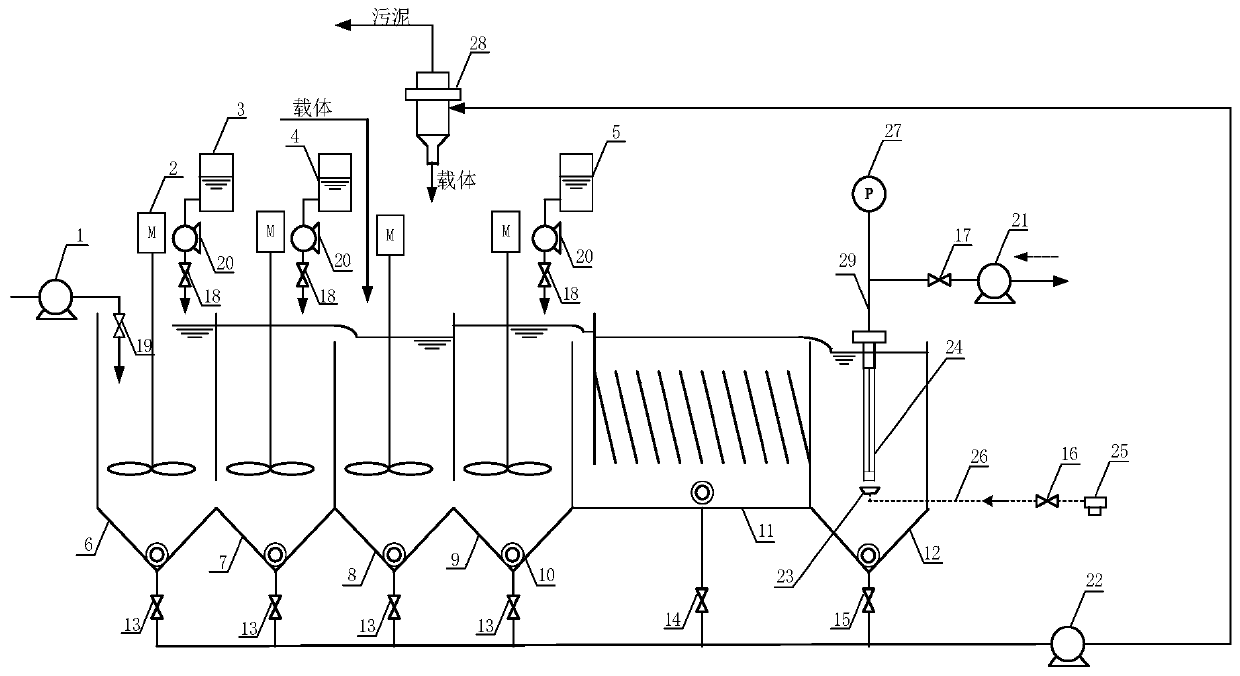

[0044] Such as figure 1 As shown, an integrated reactor for removing trace antibiotics in complex polluted surface water, including a feed pump 1 connected in sequence, a first conventional flocculation tank 6, a second conventional flocculation tank 7, a carrier flocculation mixing tank 8, a carrier flocculation tank Reaction tank 9, inclined plate settling tank 11, ultrafiltration tank 12; the lower end of the first conventional flocculation tank 6 communicates with the lower end of the second conventional flocculation tank 7, and the upper end of the second conventional flocculation tank 7 communicates with the carrier flocculation mixing tank 8, and the water overflows Enter the carrier flocculation mixing tank 8 in the same way, the carrier flocculation mixing tank 8 communicates with the lower end of the carrier flocculation reaction tank 9, the carrier flocculation reaction tank 9 communicates with the upper end of the inclined plate settling tank 11, and the inclined pl...

Embodiment 2

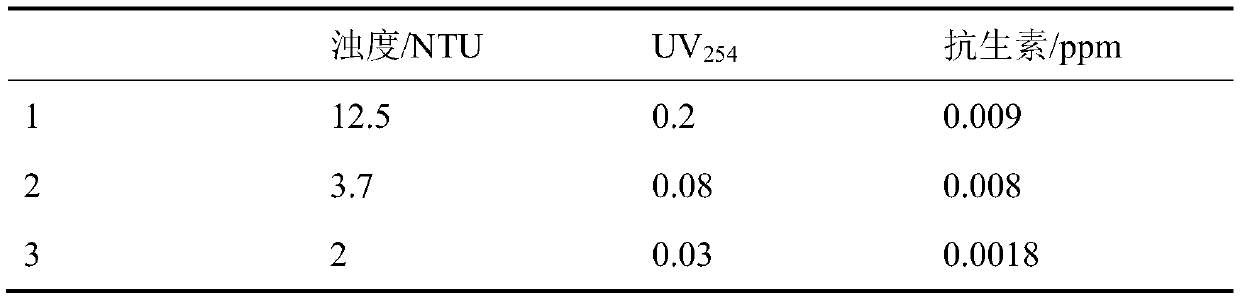

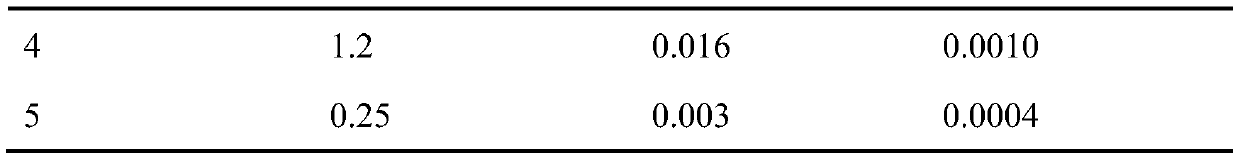

[0049] Establish the integrated reactor of embodiment 1 to carry out the removal method of trace antibiotics in complex polluted surface water: inject complex polluted surface water into the first conventional flocculation tank 6 by feed pump 1, the inflow flow is 11.1ml / min, and At the same time, open the flocculant feed valve 18 and use the flocculant dosing pump 20 to inject the alum in the inorganic flocculant storage tank 3 into the first flocculation tank 6, the dosage of alum is 10ppm, and start the mechanical agitator 2 to stir The rotation speed of the device is 200r / min, so that the composite polluted surface water and alum are fully mixed and flocculation occurs, and the surface water treated by the first conventional flocculation tank 6 flows into the second conventional flocculation tank 7 from the connection between the lower ends of the two tanks, When the water flows in, open the flocculant feed valve 18 and use the flocculant dosing pump 20 to add polyacrylamid...

Embodiment 3

[0054] Establish the integrated reactor of embodiment 1 to carry out the removal method of trace antibiotics in complex polluted surface water: inject complex polluted surface water into the first conventional flocculation tank 6 through feed pump 1, and the influent flow rate is 8.33ml / min, at the same time, open the flocculant feed valve 18 and use the flocculant dosing pump 20 to inject the alum in the inorganic flocculant storage tank 3 into the first flocculation tank, the dosage of alum is 15ppm, and start the mechanical agitator 2 , the stirring speed of the agitator is 180r / min, so that the composite polluted surface water and alum are fully mixed and flocculation occurs, and the surface water treated by the first conventional flocculation tank 6 flows into the second conventional flocculation tank 7 from the connection of the lower ends of the two ponds , open the flocculant feed valve 18 when the surface water flows in, use the flocculant dosing pump 20 to add polyac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com