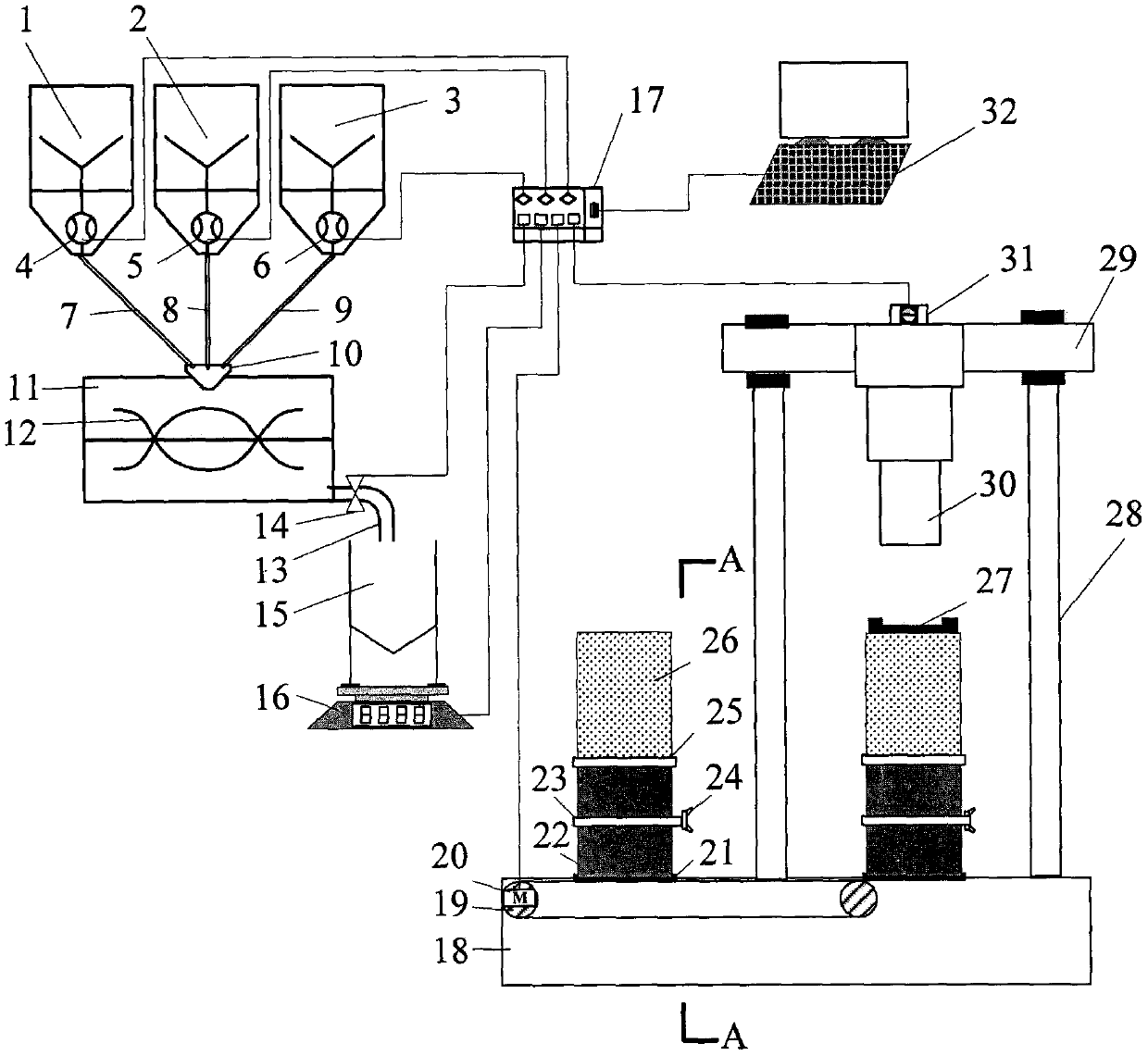

Sample making device and making method thereof for unconfined compression test

A compression test and device manufacturing technology, which is applied in the preparation of test samples, measuring devices, sampling, etc., can solve the problems of upper and lower layers, uneven density, uneven sample preparation pressure, etc., to avoid loss of moisture content, High sample removal efficiency and good sample preparation uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

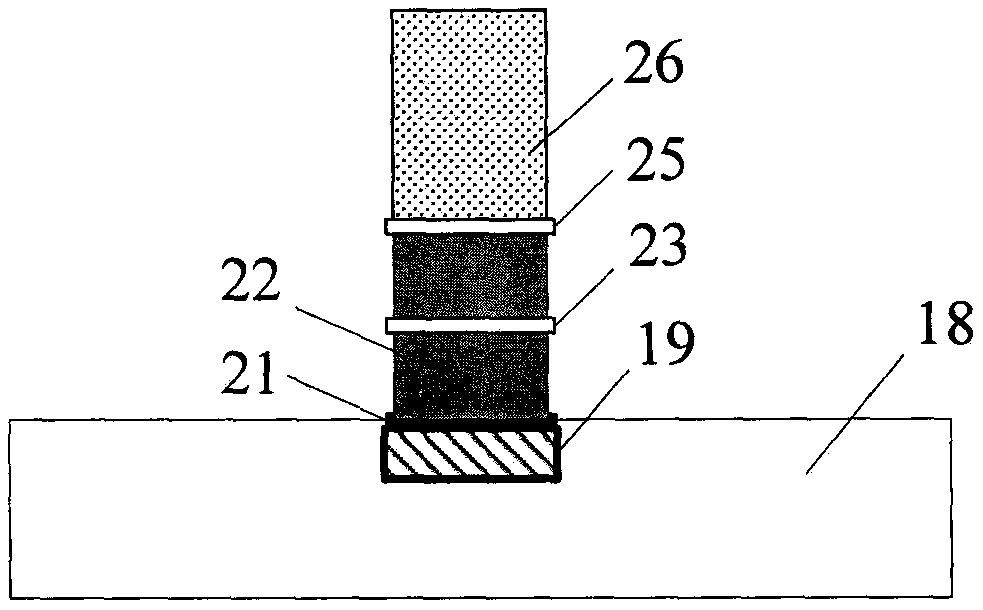

[0048] a. Material mixing: Store the air-dried and sieved silt soil, powdered curing agent lime and water in storage tank 1, powder storage tank 2 and liquid storage tank 3 respectively, and mix according to the preset curing agent. 15% water content, 30% water content and 1200g mixed usage, the flow rate and time of flow valve A4, flow valve B5 and flow valve C6 are simultaneously adjusted by collective controller 17, so that silt, lime and water pass through discharge pipe 7 , The powder outlet pipe 8 and the liquid outlet pipe 9 flow into the homogenizing device 11, the total mixture of pre-stirring is about 1500g, start the stirring blade 12 to make each component evenly mixed,

[0049] b. Mixture weighing: according to the preset sample density 2.0g / cm 3 and sample size (cylindrical sample: 5cm in diameter, 10cm in height), calculate the mixture weight (about 400g) of a single sample, adjust the flow size and time of the control valve 14 by the collective controller 17, a...

Embodiment 2

[0054] a. Material mixing: Store the sieved polluted soil, powdered cement and water into the material storage tank 1, powder storage tank 2 and liquid storage tank 3 respectively, according to the preset curing agent dosage of 20% , moisture content 30% and mixed consumption 5400g, adjust the flow rate and the time of flow valve A4, flow valve B5 and flow valve C6 simultaneously by collective controller 17, make silt soil, lime and water pass through discharge pipe 7, powder discharge respectively The pipe 8 and the liquid outlet pipe 9 flow into the homogenizing device 11, and the total pre-stirred mixture is about 6000g, and the stirring blade 12 is started to mix the components evenly.

[0055] b. Mixture weighing: according to the preset sample density 1.8g / cm 3 and sample size (cube sample: side length 10cm), calculate the mixture weight (about 1800g) of a single sample, adjust the flow size and time of the control valve 14 by the collective controller 17, weigh the requ...

Embodiment 3

[0060] a. Material mixing: Store the sieved sand, powdered cement and water in the material storage tank 1, powder storage tank 2 and liquid storage tank 3 respectively, and mix according to the preset water-cement ratio of 0.8 and The consumption is 15000g, and the flow rate and time of flow valve A4, flow valve B5 and flow valve C6 are simultaneously adjusted through the collective controller 17, so that the silt, lime and water pass through the discharge pipe 7, the powder discharge pipe 8 and the liquid discharge pipe 9 respectively Flow into the homogenizing device 11, the pre-stirred total mixture is about 15000g, start the stirring blade 12 to make each component evenly mixed,

[0061] b. Mixture weighing: according to the preset sample density 2.5g / cm 3 And sample size (cuboid sample: section side length 10cm, height 20cm), calculate the mixture weight (about 5000g) of single sample, adjust the flow size and time of control valve 14 by collective controller 17, weigh s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com