Wafer alignment method and pre-alignment mechanism thereof and conveying mechanical arm

A technology of robotic arms and handling machinery, which is applied in the field of IC manufacturing, can solve the problems of increasing the handling time of a single wafer, increasing the outline size of the whole machine equipment, increasing the time of wafer handling, etc., achieving simple structure, reduced size, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

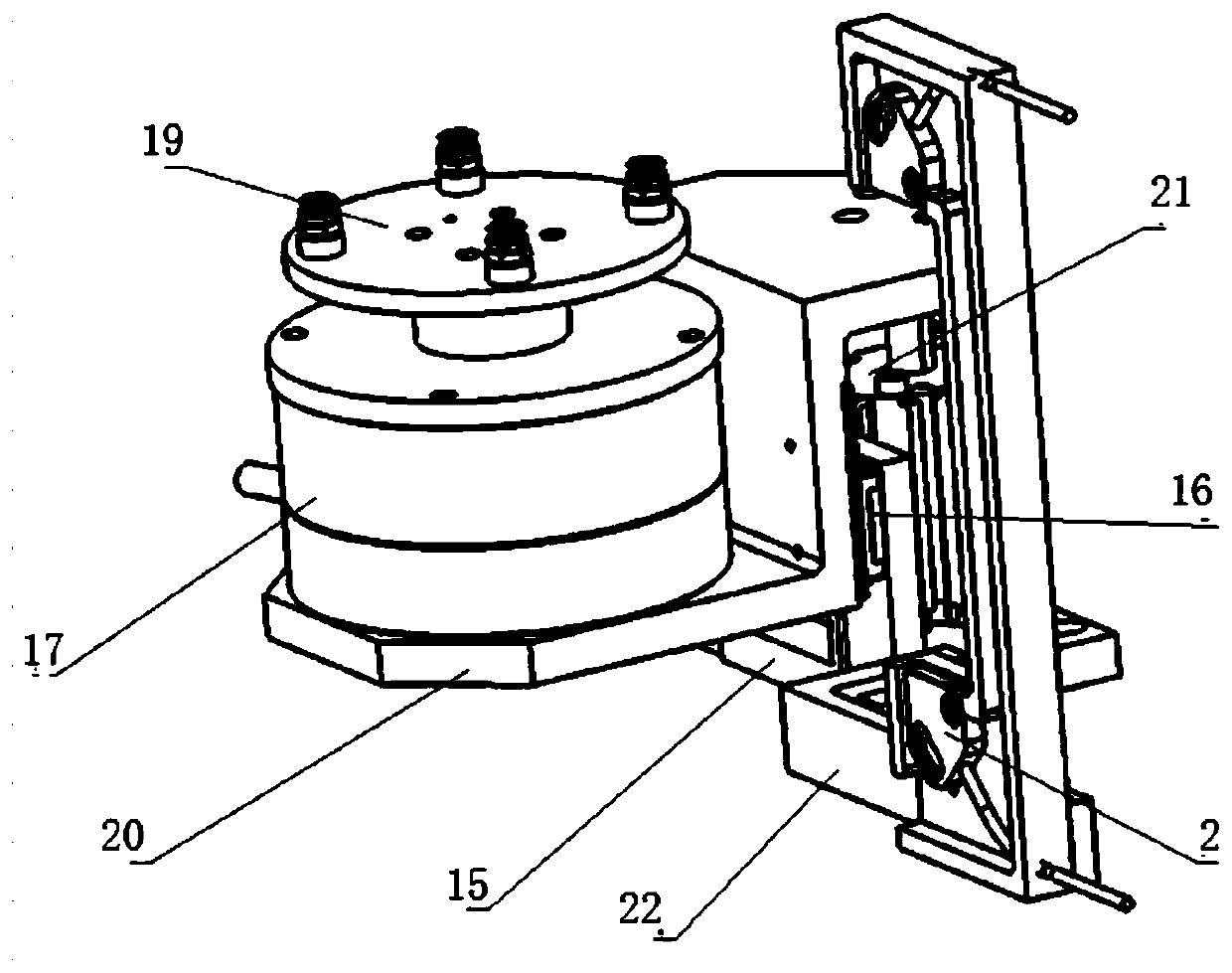

[0054] In terms of the mechanical structure of this embodiment, the wafer pre-alignment mechanism in the present invention, such as image 3 As shown, it is mainly composed of a drive motor mount 20, a direct drive motor 17, a vacuum chuck assembly 19, a drive cylinder 21, a guide rail slider mechanism 16, a connecting plate 15, a sensor assembly 2 and a sensor mounting plate 22.

[0055] In the pre-alignment mechanism of the present invention, the vacuum chuck assembly 19 used to contact the wafer is driven by the drive motor 17, and all the drive motors and the vacuum chuck assembly 19 are installed on the drive motor mount 20. The drive motor mount 20 can be driven up and down by the cylinder 21 and can be used as an auxiliary guide by means of the guide rail slider mechanism 16 . And the fixed support (connecting plate 15) can be connected with the mounting plate 4 at the bottom of the manipulator attached to it by bolts. The sensor assembly 2 is used to find the center o...

Embodiment 2

[0062] This embodiment describes a wafer handling robotic arm with pre-alignment function of the present invention, which mainly includes a set of direct drive motor (drive motor), a set of synchronous belt transmission system, and a set of guide rail slider system , a set of end effectors, a support mechanism and a set of wafer pre-alignment mechanism, wherein the wafer pre-alignment mechanism includes another set of direct drive motor (drive motor), guide rail slider mechanism, and a set of cylinder system , a wafer chuck, a sensor assembly and a drive motor mounting seat, wherein, in order to ensure the overall stability of the mechanism and the load of the guide rail slider is not overloaded, the guide rail slider mechanism can be two sets in this specific embodiment.

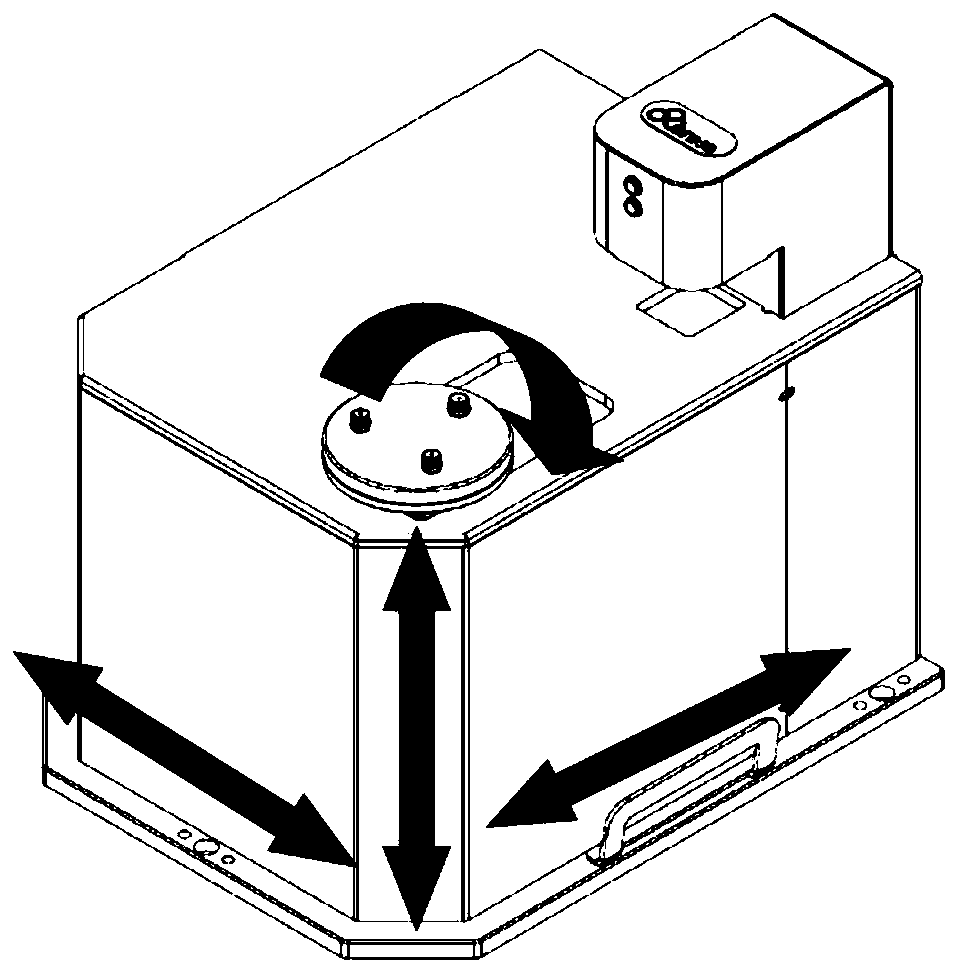

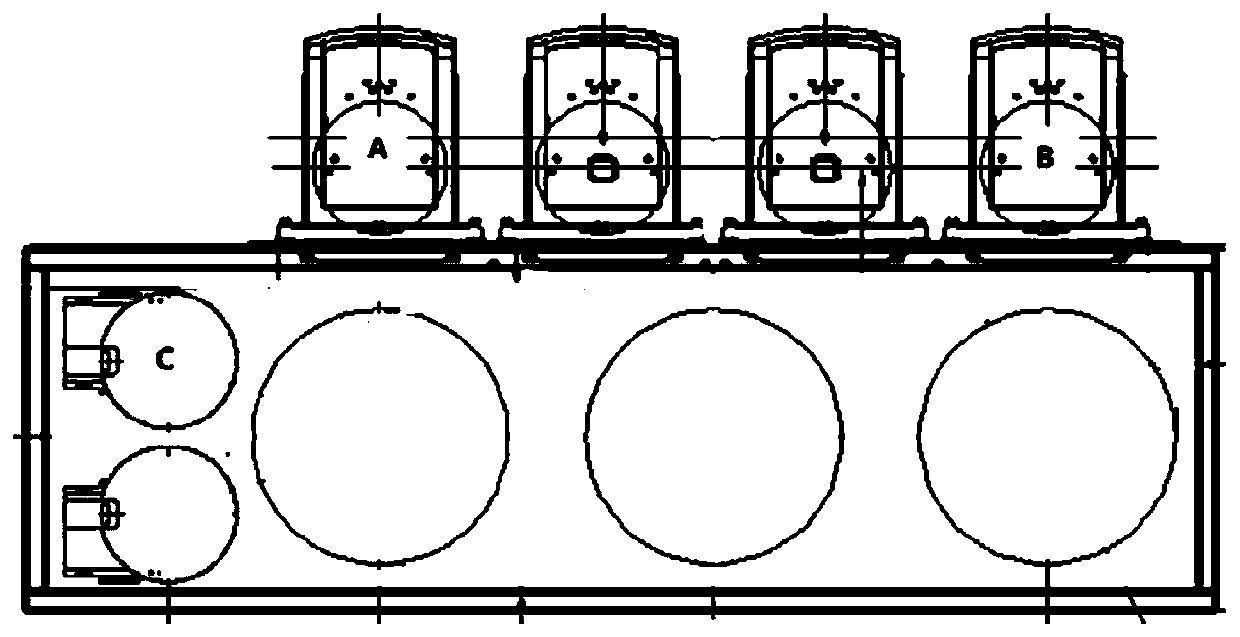

[0063] see Image 6 , is a schematic structural diagram of a specific implementation of the wafer handling robot arm with pre-alignment function of the present invention. Such as Image 6 As shown, the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com