Three-dimensional instant-heating circulation steam separator and three-dimensional instant-heating circulation steam separation system

A steam separator and steam separation technology, used in fluid heaters, air heaters, steam cooking utensils, etc., can solve the problems of low heat enthalpy, heavy steam moisture, and high steam humidity, and achieve increased heating rate and improved cooking. Hygiene, the effect of ensuring hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

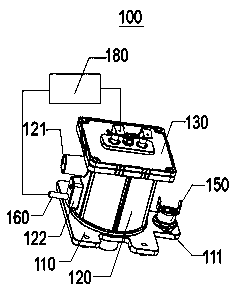

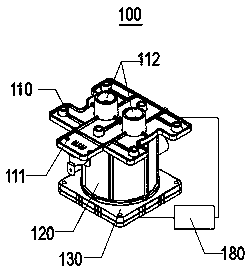

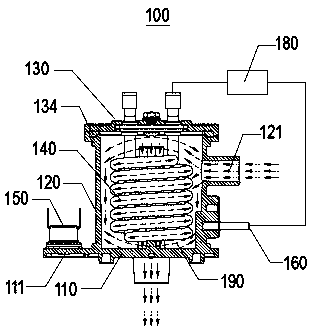

[0039] Please refer to Figure 1-Figure 4, the present embodiment provides a three-dimensional thermal circulation steam separator 100, which includes a base 110, a housing 120, a cover plate 130, a heating tube 140, a KSD temperature control protector 150, an NTC temperature sensor 160, and a heat conduction sensing corner block 170 And electric control board IC chip 180. Among them, the base 110, the housing 120, and the cover plate 130 are assembled into a cylindrical protective shell, and a cavity 190 is formed inside the protective shell to heat and circulate steam and condensed water. In the cavity 190, the steam is heated, and the high temperature and pressure increase. , The enthalpy value increases and the humidity decreases. The heat pipe is detachably connected to the cover plate 130 and extends toward the cavity 190 inside the protective case. Both the KSD temperature control protector 150 and the heat conduction sensing corner block 170 for overheating and overt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com