Automatic control system for box structure processing

An automatic control system and box structure technology, applied in the direction of manufacturing tools, presses, etc., can solve the problems of difficult control of the welding process, low production efficiency, and prone to defects, etc., to improve the tolerance accuracy of the main girder box, The effect of improving production efficiency and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

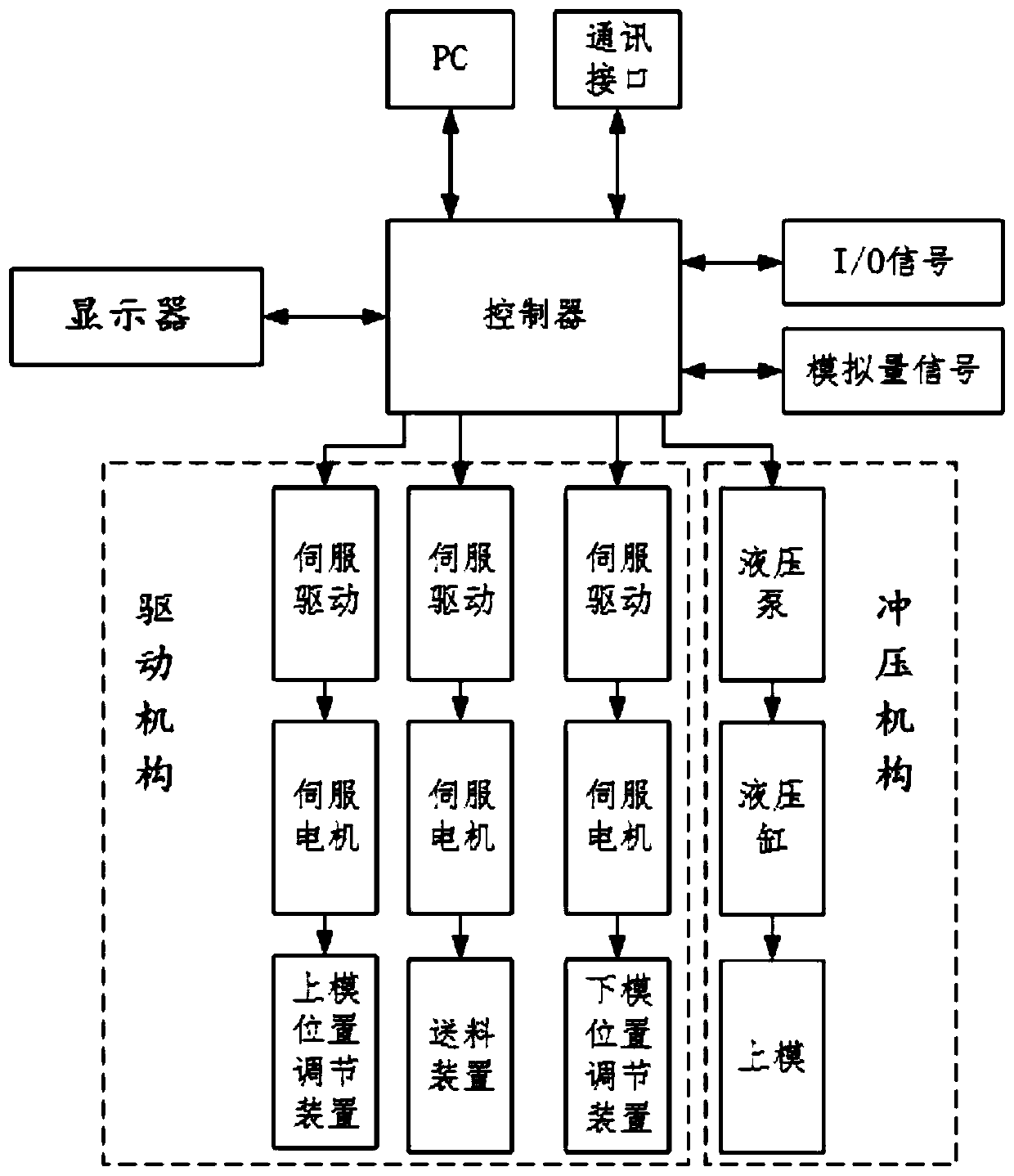

[0061] As an embodiment, the drive mechanism includes a first servo motor, and the first servo motor is connected to the upper mold position adjustment device;

[0062] A second servo motor, the second servo motor is connected to the feeding device;

[0063] A third servo motor, the third servo motor is connected with the lower mold position adjusting device.

[0064] In this embodiment, the three sides of the box body (for example: the main girder box body of a crane) can be processed and formed at one time, which improves the process of forming the main girder in sections and then welding and assembling it multiple times, improves the inconvenience caused by manual assembly and section welding, and improves The body position tolerance accuracy of the main girder box improves the processing efficiency and saves labor costs and power consumption.

[0065] This embodiment realizes the automatic control of the box structure processing equipment, and the box body with a larger l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com