Anhydrous vitamin A emulsion and preparation method thereof

A technology of vitamin and water emulsion, which is applied in the direction of pharmaceutical formulations, dressing preparations, cosmetic preparations, etc., to achieve the effect of eliminating wrinkles, good anti-oxidation and anti-aging effects, and maintaining skin vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

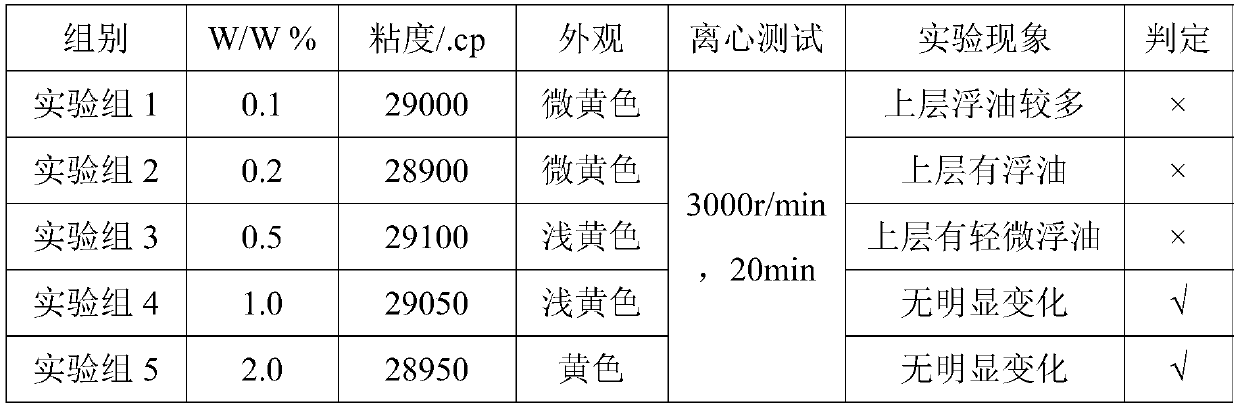

Method used

Image

Examples

Embodiment 1

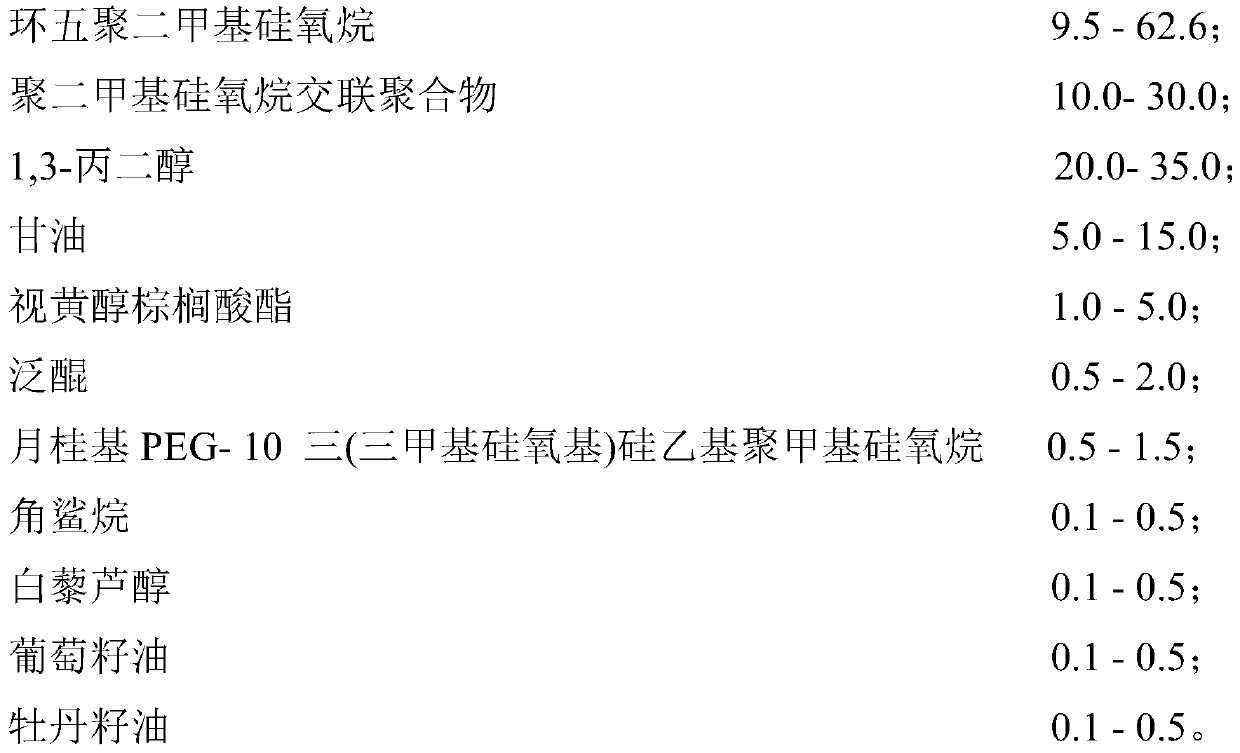

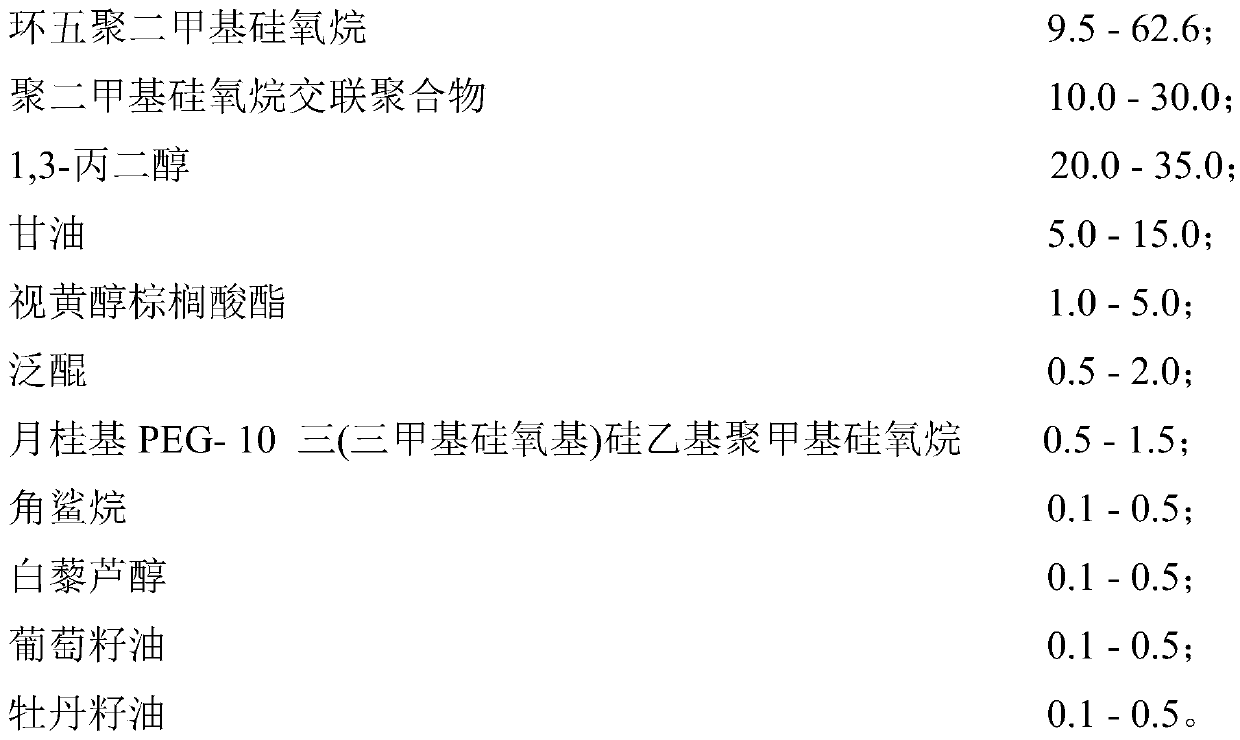

[0057] This embodiment provides a vitamin A anhydrous emulsion, including the following raw materials in parts by weight:

[0058] 9.5 parts by weight of cyclopentasiloxane, 30 parts by weight of dimethicone crosspolymer, 35 parts by weight of 1,3-propanediol, 15 parts by weight of glycerin, 5 parts by weight of retinyl palmitate 2 parts by weight of ubiquinone, 0.5 parts by weight of lauryl PEG-10 tris(trimethylsiloxy)silylethyl polymethicone, 0.1 parts by weight of squalane, 0.1 parts by weight of resveratrol, Grape seed oil 0.1 weight part, peony seed oil 0.1 weight part.

[0059] Its preparation method is as follows:

[0060] (1) Take cyclopentasiloxane and add it to the main pot;

[0061] (2) Add dimethicone crosspolymer and lauryl PEG-10 tris(trimethylsiloxy)silylethylpolymethicone to the cyclopentasiloxane from step 1 Siloxane, stirred at room temperature until there are no particles, to obtain a mixed solution;

[0062] (3) Clean and disinfect the reaction equipmen...

Embodiment 2

[0066] This embodiment provides a vitamin A anhydrous emulsion, including the following raw materials in parts by weight:

[0067] 62.5 parts by weight of cyclopentasiloxane, 10 parts by weight of dimethicone crosspolymer, 20 parts by weight of 1,3-propanediol, 5 parts by weight of glycerin, 1 part by weight of retinyl palmitate 0.5 parts by weight of ubiquinone, 1.5 parts by weight of lauryl PEG-10 tris(trimethylsiloxy) silylethyl methicone, 0.5 parts by weight of squalane, 0.5 parts by weight of resveratrol, Grape seed oil 0.5 weight part, peony seed oil 0.5 weight part.

[0068] Its preparation method is as follows:

[0069] (1) Take cyclopentasiloxane and add it to the main pot;

[0070] (2) Add dimethicone crosspolymer and lauryl PEG-10 tris(trimethylsiloxy)silylethylpolymethicone to the cyclopentasiloxane from step 1 Siloxane, stirred at room temperature until there are no particles, to obtain a mixed solution;

[0071] (3) Clean and disinfect the reaction equipment,...

Embodiment 3

[0075] This embodiment provides a vitamin A anhydrous emulsion, including the following raw materials in parts by weight:

[0076] Cyclopentasiloxane 9.5 parts by weight, Dimethicone crosspolymer 10 parts by weight, 1,3-Propanediol 35 parts by weight, Glycerin 5 parts by weight, Retinyl palmitate 5 parts by weight 0.5 parts by weight of ubiquinone, 1.5 parts by weight of lauryl PEG-10 tris(trimethylsiloxy)silylethyl methicone, 0.1 parts by weight of squalane, 0.1 parts by weight of resveratrol, Grape seed oil 0.5 weight part, peony seed oil 0.5 weight part.

[0077] Its preparation method is as follows:

[0078] (1) Take cyclopentasiloxane and add it to the main pot;

[0079] (2) Add dimethicone crosspolymer and lauryl PEG-10 tris(trimethylsiloxy)silylethylpolymethicone to the cyclopentasiloxane from step 1 Siloxane, stirred at room temperature until there are no particles, to obtain a mixed solution;

[0080] (3) Clean and disinfect the reaction equipment, then add 1,3-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com