Flexible bulletproof stab-resistant material and preparing method thereof

A bullet-proof, stab-proof, and flexible technology, which is applied in the direction of protective equipment, protective equipment, chemical instruments and methods, etc., can solve the problems of heavy weight of personal protective equipment, poor wearing comfort, difficulty in balancing protective performance and flexibility, etc., to achieve Comfortable bulletproof and stabproof effect, improvement of wearing comfort, excellent bulletproof and stabproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

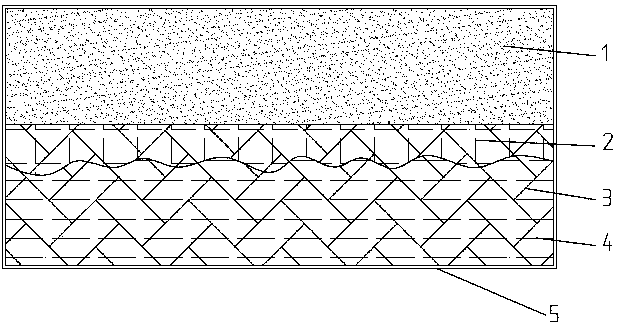

[0022] As shown in Figure 1, a flexible bullet-proof and stab-proof material is prepared by the following steps: (1) The gram weight is 20g / m 2 The EVA melt film is laid on a gram weight of 200g / m 2 The upper surface of the aramid fiber fabric was heated to 160° C., and hot-pressed to make the EVA material penetrate into the upper side of the fiber fabric to obtain Material 1. (2) Prepare the mixed solution of silicon carbide particles and phenolic resin by mechanical stirring method. The mass ratio of silicon carbide particles and phenolic resin is 1:1, and the average particle size of silicon carbide particles is 50 μm. Brush the mixed solution on the fiber fabric of material 1 3 On the side containing thermoplastic elastomer 2, control the brushing amount to 100g / m 2 , 150°C high temperature flattening, after the resin is cured, the mold is released, and the passivation layer 1 is produced to obtain material 2; (3) The shear thickening liquid with a solid content of 66% is...

Embodiment 2

[0025] As shown in Figure 1, a flexible bullet-proof and stab-proof material is prepared by the following steps: (1) The gram weight is 10 g / m 2 The TPU melt film is laid on a gram weight of 150g / m 2 The upper surface of the PBO fiber fabric is heated to 180° C., and hot-pressed to form the TPU material into the upper side of the fiber fabric 3 to obtain material 1. (2) The mixture of boron carbide particles and vinyl ester resin is prepared by mechanical stirring method, the mass ratio of boron carbide particles and vinyl ester resin is 1:2, the average particle size of boron carbide particles is 100 μm, and the mixture is painted on The fiber fabric of material 1 contains one side of thermoplastic elastic material, and the control brushing amount is 120g / m 2 , press at room temperature, release the mold after the resin is cured, and produce a passivation layer 1 to obtain material 2; (3) Dilute the shear thickening liquid with a solid content of 70% with methanol at a volum...

Embodiment 3

[0028]As shown in Figure 1, a flexible bulletproof and stab-proof material is prepared by the following steps: (1) The gram weight is 15g / m 2 The EVA melt film is laid on a gram weight of 300g / m 2 The upper surface of the aramid fiber fabric is heated to 160° C., and hot-pressed to form the EVA material into the upper side of the fiber fabric 3 to obtain material 1. (2) Prepare the mixed solution of silicon carbide particles and epoxy resin by mechanical stirring method. The mass ratio of silicon carbide particles and epoxy resin is 1:3, and the average particle size of silicon carbide particles is 10 μm. Brush the mixed solution on material 1 On the side of the fiber fabric containing thermoplastic elastic material, the control brushing amount is 150g / m 2 , high temperature pressing at 150°C, release the mold after the resin is cured, make a passivation layer 1, and obtain material 2; (3) Dilute the shear thickening liquid with a solid content of 68% with acetone at a ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com